Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Vertical Insulating Glass Production Line LJBZ2025 for glass

production machinery

LIJIANG production line adopts the latest technology, its main purpose is to create high-end

quality, to provide customers with the latest production technology, improve production efficiency,

save production costs and produce maximum benefits.

Now LIJIANG mainly has two kinds of IG line with different two different technologies. One uses

transfer wheels to transport glass, and the other is a new technology that uses air-floating

technology to transport glass. This new technology is to prevent the glass from being contaminated

by wheels and leaving traces, so new technology is used to improve the IG production’s high quality.

LJBZ2025 vertical hollow glass flat pressure production line can complete the following functions:

glass cleaning, aluminum frame placement, ordinary double glass, ordinary three glass, double

glass aeration and three glass aeration.

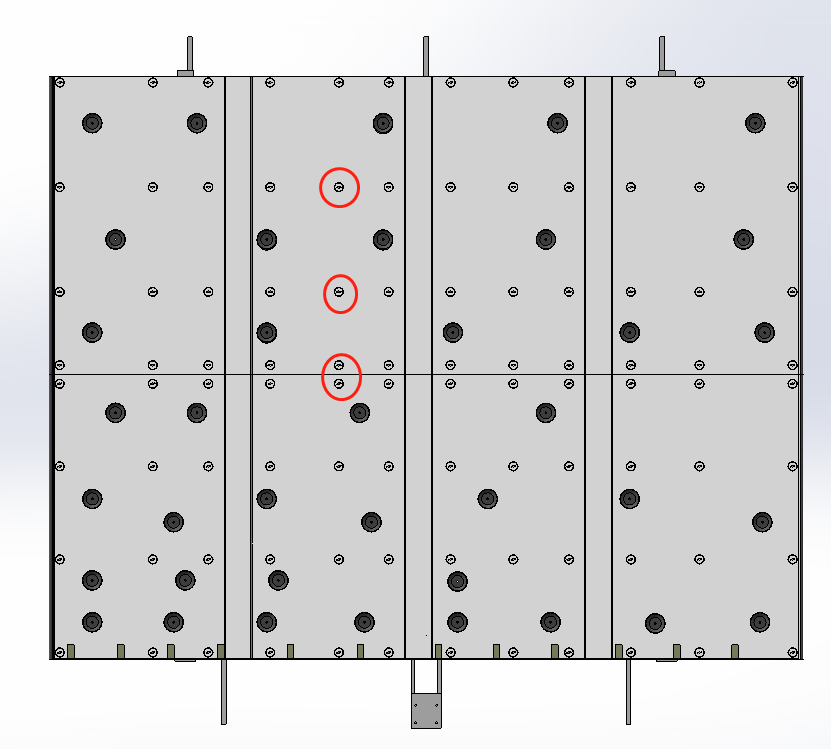

LJBZ2025 is a special equipment in aluminum hollow glass production. The production line has

the advantages of small area, high efficiency, reliable performance and convenient maintenance.

It is the first one in China to use adjustable points to ensure that the platen will never deform.

We adopt CNC technology into the pressing board. We designed the adjustable points inside the

pressing board to keep the back plate straight all the time. In China, except LIJIANG, no one can

guarantee that the pressing board will remain vertical and straight all the time after used 10 or 20

years. However, we solve this problem already.

The washing machine uses 304 stainless steel materials

The whole washing and drying section adopt 304 stainless steel materials, including the plate

and interior spare parts.

| Max. glass size | 2500mm*3500mm |

| Max glass size for filling gas | 2500mm*3200mm |

| Min. glass size | 280mm*450mm |

| Glass thickness | 3-15mm |

| Insulating glass thickness | 60mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed | 45m/min |

| Washing brushes | 3 pairs of soft brushes with 0.1mm hair |

| Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50HZ 40KW |

| Dimension | 23500*3500*3700mm |

| Weight | 6500kg |

| NAME | ORIGIN | BRAND |

| Transfer motor | Germany | SIEMENS |

| Brush motor | Germany | SIEMENS |

| Servo motor | Germany | SIEMENS |

| PLC | Germany | SIEMENS |

| Low voltage electrical appliance | Germany | SIEMENS |

| Frequency converter | Germany | SIEMENS |

| Micro Switch | Taiwan | TEND |

| Button and indicator light | France | SCHNEIDER |

| touch screen | Taiwan | WEINVIEW |

| Intermediate relay | Japan | OMRON |

| Water pump | China | LINGXIAO |

| Guide | Taiwan | HIWIN |

| Pneumatic Components | Taiwan | AIRTAC |

| electric gauge | China | MIRAN |

| Photoelectric switch | Korea | AUTONICS |

| JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD | ||