Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

insulating glass pruduction ,Double glass three glass high efficiency stable operation

LIJIANG production line adopts the latest technology, its main purpose is to create high-end quality, to provide customers with the latest production technology, improve production efficiency, save production costs and produce maximum benefits.

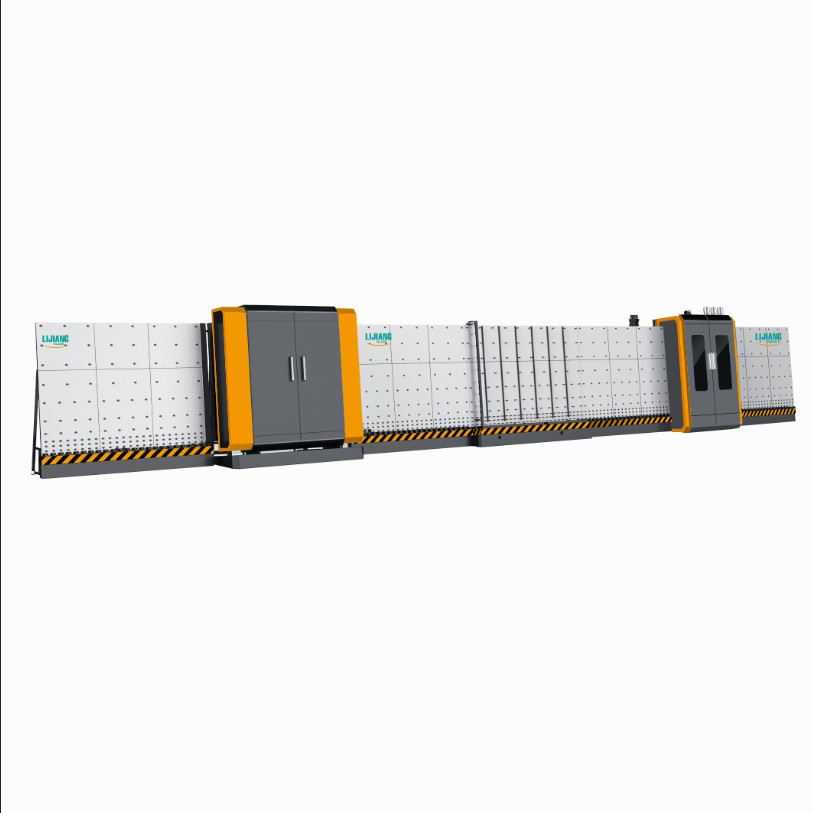

Now LIJIANG mainly has two kinds of IG line with different two different technologies. One (Picture 1) uses transfer wheels to transport glass, and the other (Picture 2) is a new technology that uses air-floating technology to transport glass. This new technology is to prevent the glass from being contaminated by wheels and leaving traces, so new technology is used to improve the IG production’s high quality.

The front and back transfer wheel are all moved, all actively transferred. It can guarantee the big and thick glass pass through smoothly.

The new air – floating technology uses air to support glass and transfer glass. When glass is washed clearly from the washing machine, using air to transport the glass, it won't be contaminated. Ensure that the produced insulating glass is of the highest quality.

This sensor is installed before washing machine. It can automatically recognize Low-e glass surface fast and precisely, preventing the glass from dropping Low-e surface.

Production line debugging steps

1.Place the machine in position from incoming to outgoing material

in sequence

2.Use a level gauge or level and two pieces of 1500X1500 glass (5mm

thickness, white glass with fine grinding edge) to level each

section of the machine so that the two pieces of glass are level

above and below a plane

3.Install the water pipe of the fan, air pipe and water tank

| NAME | ORIGIN | BRAND |

| Transfer motor | Germany | SIEMENS |

| Brush motor | Germany | SIEMENS |

| Servo motor | Germany | SIEMENS |

| PLC | Germany | SIEMENS |

| Low voltage electrical appliance | Germany | SIEMENS |

| Frequency converter | Germany | SIEMENS |

| Micro Switch | Taiwan | TEND |

| Button and indicator light | France | SCHNEIDER |

| touch screen | Taiwan | WEINVIEW |

| Intermediate relay | Japan | OMRON |

| Water pump | China | LINGXIAO |

| Guide | Taiwan | HIWIN |

| Pneumatic Components | Taiwan | AIRTAC |

| electric gauge | China | MIRAN |

| Photoelectric switch | Korea | AUTONICS |

| JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD | ||

Power on and work

After the machine is powered on, unscrew the emergency stop switch on the operation panel of the flat press and washing machine, press the reset or start button on the operation panel of the plate press, and check whether the knob switches on the operation panel of the flat press and washing machine are in the corresponding state.

Production of insulating glass

First, put two pieces of glass in the feeding section in turn, step

on the foot, let the glass into the washing section, according to

the then temperature adjustment panel stepless speed control knob

or in the touch screen to adjust the speed of the washing machine,

adjust the speed of washing air drying.

Glass washing section, by washing discharge section, to the box on

the checking period of stop, check whether the glass is clean,

qualified after stepping on foot switch to the first piece of glass

into the plate or piece of positioning, bracket or beam hold a

glass plate before pressing to absorb the glass in the past, board

face to open in place, in washing discharge period of the second

piece of glass in the middle of the first piece of glass will leave

frame period since the launch, into the box on the check period,

positioning stop, qualified manual frame stepping on foot switch,

the glass into pieces positioning pressing. The compressed

insulating glass can be automatically transferred to the feeding

section of the automatic sealing glue line. (into the turntable, to

photoelectric stop. Step on the foot and the tilting table will

fall down automatically. After the glass is removed, step on the

foot and the tilting table will rise. (select whether to use the

rollover function of the rollover table according to the size of

the glass) (rollover table is configured for selection)