Guangdong Blue Whale Ultrasonic Equipment Co;Ltd |

|

Verified Suppliers

|

|

Blue Whale Two Tanks 96L Industrial Ultrasonic Cleaner with Cleaning Heating and Spraying Function

1. What is the ultrasonic cleaning technology?

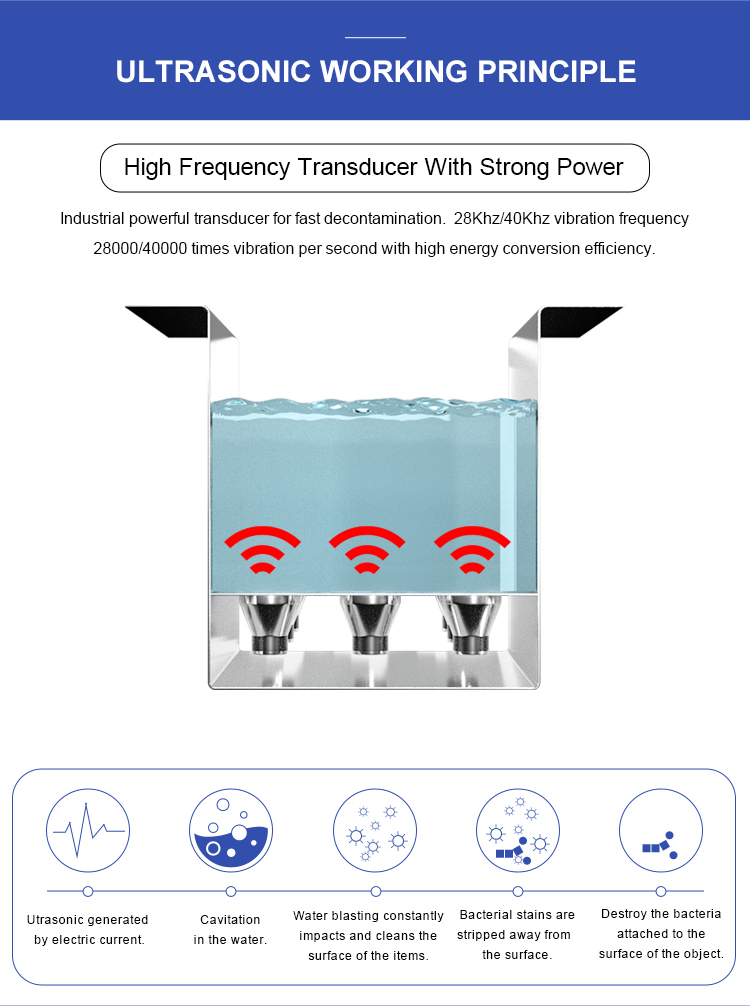

Ultrasonic cleaning technology involves the use of high-frequency sound waves to create microscopic bubbles in a liquid cleaning solution, which then implode near the surface of objects being cleaned. This implosion generates intense scrubbing action and helps dislodge and remove contaminants from the objects' surfaces. Here are the key components and principles of ultrasonic cleaning technology:

Ultrasonic Transducers: Ultrasonic transducers are the core components of an ultrasonic cleaning system. They convert electrical energy into high-frequency sound waves through a process called piezoelectric effect. The transducers are typically made of piezoelectric crystals that vibrate rapidly when an electrical signal is applied to them.

Generator: The generator is an electronic device that provides the electrical energy needed to power the ultrasonic transducers. It generates high-frequency electrical signals that are sent to the transducers, causing them to vibrate at the desired frequency.

Cleaning Tank: The cleaning tank, also known as the ultrasonic bath or chamber, is a container that holds the cleaning solution and the objects to be cleaned. It is typically made of stainless steel or a material that is resistant to the cleaning solution and can withstand the vibrations generated by the transducers.

Cleaning Solution: The cleaning solution used in ultrasonic cleaning is a mixture of water and specialized detergents, solvents, or additives. The selection of the cleaning solution depends on the type of contaminants to be removed and the material being cleaned. The solution should be chosen to optimize cleaning effectiveness while considering material compatibility and safety.

Cavitation: When the transducers vibrate, they create high-frequency sound waves in the cleaning solution. These sound waves produce alternating high-pressure and low-pressure cycles, causing microscopic bubbles known as cavitation bubbles to form and collapse rapidly. The collapsing bubbles generate localized pressure differentials and intense scrubbing action, helping to dislodge and remove contaminants from the object's surface.

Cleaning Process: The objects to be cleaned are immersed in the cleaning solution within the ultrasonic cleaning tank. The ultrasonic generator powers the transducers, which emit high-frequency sound waves into the solution. As the sound waves propagate through the solution, they create cavitation bubbles that implode near the objects' surfaces, effectively cleaning them.

Frequency and Power: Ultrasonic cleaning systems operate at various frequencies, typically ranging from 20 kHz to 400 kHz. The frequency selection depends on factors such as the size of contaminants, the material being cleaned, and the desired cleaning intensity. Higher frequencies are generally used for delicate cleaning, while lower frequencies are suitable for heavy-duty cleaning tasks. The power level of the ultrasonic system can also be adjusted to control the intensity of the cleaning process.

Ultrasonic cleaning technology offers several advantages, including efficient and effective cleaning of complex shapes and hard-to-reach areas, reduced manual labor, shorter cleaning times, and the ability to clean a wide range of materials. However, it's important to consider material compatibility, the type of contaminants, and follow proper guidelines to ensure safe and successful cleaning outcomes.

2. Product Features:

1). Working process: the 1st tank ultrasonic cleaning with heating,

remove the rust, grease and dust from the cleaning items. The 2nd

tank high pressure spraying to provide deep cleaning service. The

alarm buzzes once complete the spraying process.

2). The inner tank material: the use of 304 stainless steel,

thickened to 2mm, manual argon welding, strong and durable;

3). Adjustable time: 1-99 minutes/hour adjustable, can be opened

often;

4). Memory function: the device has an independent memory chip, and

there is no need to reset over and over after the time is set;

5). Equipment power cord: the use of industrial thickened power

cord, safe and durable;

6). Industrial grade transducer: the use of industrial shock head,

strong force and good effect, can work 24 hours uninterrupted;

7). Generator control system: independent generator control system,

flexible control, can be set according to the user's cleaning needs

to adjust the ultrasonic power;

8). Heating automatic constant temperature system: 20-95 degrees

adjustable, equipped with stainless steel heating tube, fast

heating speed.

3. Double Tanks Industrial Ultrasonic Cleaner CHS Series:

Ultrasonic Cleaning, Heating, High Pressure Spraying

4. What are some common applications of ultrasonic cleaning technology?

Ultrasonic cleaning technology is widely used across various industries for its ability to effectively clean a wide range of objects and materials. Here are some common applications of ultrasonic cleaning:

Precision and Industrial Parts Cleaning: Ultrasonic cleaning is extensively used for cleaning precision parts, such as automotive components, aerospace parts, electronic circuit boards, medical instruments, jewelry, and optical lenses. The technology's ability to reach intricate and hard-to-reach areas makes it suitable for removing contaminants like dirt, oils, grease, flux residues, and fingerprints.

Medical and Dental Equipment: Ultrasonic cleaning is employed in medical and dental facilities to clean instruments, surgical tools, dental prosthetics, and other medical equipment. It helps remove biological residues, blood, tissue fragments, and other contaminants from the surfaces, ensuring proper hygiene and sterilization.

Jewelry and Watch Cleaning: Jewelers and watchmakers use ultrasonic cleaning to restore the shine and cleanliness of jewelry pieces, watches, and gemstones. The gentle yet effective action of ultrasonic waves can remove dirt, oils, and polishing compounds from intricate settings and crevices.

Automotive and Aerospace Industry: Ultrasonic cleaning is widely used in the automotive and aerospace industries to clean engine parts, fuel injectors, carburetors, pistons, valves, bearings, and other components. It helps remove carbon deposits, oils, and grease, improving performance and extending the lifespan of the parts.

Electronics and PCB Manufacturing: Ultrasonic cleaning plays a vital role in the electronics industry for cleaning printed circuit boards (PCBs), electronic components, connectors, and delicate electronic assemblies. It helps remove flux residues, soldering flux, contaminants, and dust from PCBs and electronic parts, ensuring optimal functionality and reliability.

Restoration and Conservation: Ultrasonic cleaning is utilized in the restoration and conservation of artifacts, antiques, and delicate historical objects. It can gently remove dirt, soot, tarnish, and other surface contaminants without causing damage to the original material.

Laboratory Equipment Cleaning: Ultrasonic cleaning is employed in laboratories to clean glassware, lab equipment, sample containers, and scientific instruments. It helps remove chemicals, residues, and contaminants, ensuring accurate and reliable experimental results.

Optics and Photographic Equipment: Ultrasonic cleaning is commonly used in the optics and photography industry to clean lenses, camera filters, telescopes, binoculars, and other optical equipment. It can effectively remove dust, oils, smudges, and fingerprints, improving the clarity and performance of the optics.

These are just a few examples of the diverse applications of ultrasonic cleaning technology. The versatility, efficiency, and precision of ultrasonic cleaning make it a valuable tool in industries that require thorough and effective cleaning of various objects and materials.

5. Customer's Cleaning Feedback:

6. What cleaning agent can be used for industrial ultrasonic cleaner?

The choice of cleaning agent for an industrial ultrasonic cleaner depends on the specific application, the type of contaminants to be removed, and the material being cleaned. Here are some commonly used cleaning agents for industrial ultrasonic cleaning:

Water-Based Detergents: Water-based detergents are widely used in industrial ultrasonic cleaning. They are effective for removing general contaminants like dirt, oils, greases, and light residues. Water-based detergents are often mild and safe for use on a variety of materials, including metals, plastics, ceramics, and glass.

Solvent-Based Cleaners: Solvent-based cleaners are suitable for removing heavy oils, greases, waxes, and stubborn contaminants from industrial parts. These cleaners are formulated with organic solvents such as hydrocarbons or alcohol-based solutions. Solvent-based cleaners should be chosen based on material compatibility and safety considerations.

Alkaline Cleaners: Alkaline cleaners, also known as degreasers, are effective for removing tough oil, grease, and carbon-based contaminants. These cleaners have high pH levels and are suitable for cleaning industrial components made of metals, alloys, and some plastics. Care should be taken to select an alkaline cleaner that is compatible with the specific material being cleaned.

Acidic Cleaners: Acidic cleaners are used for removing scale, rust, mineral deposits, and oxide layers from metals and certain surfaces. Acidic cleaners are typically used in specific industrial applications where acid-compatible materials are being cleaned. It is important to handle acidic cleaners with care and follow safety guidelines.

Enzymatic Cleaners: Enzymatic cleaners are designed to break down and remove organic contaminants such as proteins, blood, and biological residues. They are commonly used in industries such as healthcare, laboratories, and food processing. Enzymatic cleaners are generally safe for use on a wide range of materials, but compatibility should always be verified.

When selecting a cleaning agent, it is crucial to consider factors such as material compatibility, safety, environmental impact, and any industry-specific regulations or guidelines. It's advisable to consult with cleaning agent manufacturers or suppliers who can provide recommendations based on your specific cleaning requirements and the materials being cleaned in your industrial ultrasonic cleaner.