Guangdong Blue Whale Ultrasonic Equipment Co;Ltd |

|

Verified Suppliers

|

|

Blue Whale Two Tanks SUS304 Industrial 45L Ultrasonic Cleaner

with Cleaning Heating Spraying Function

1. Some basic knowledge about ultrasonic cleaning technology that you might need to know.

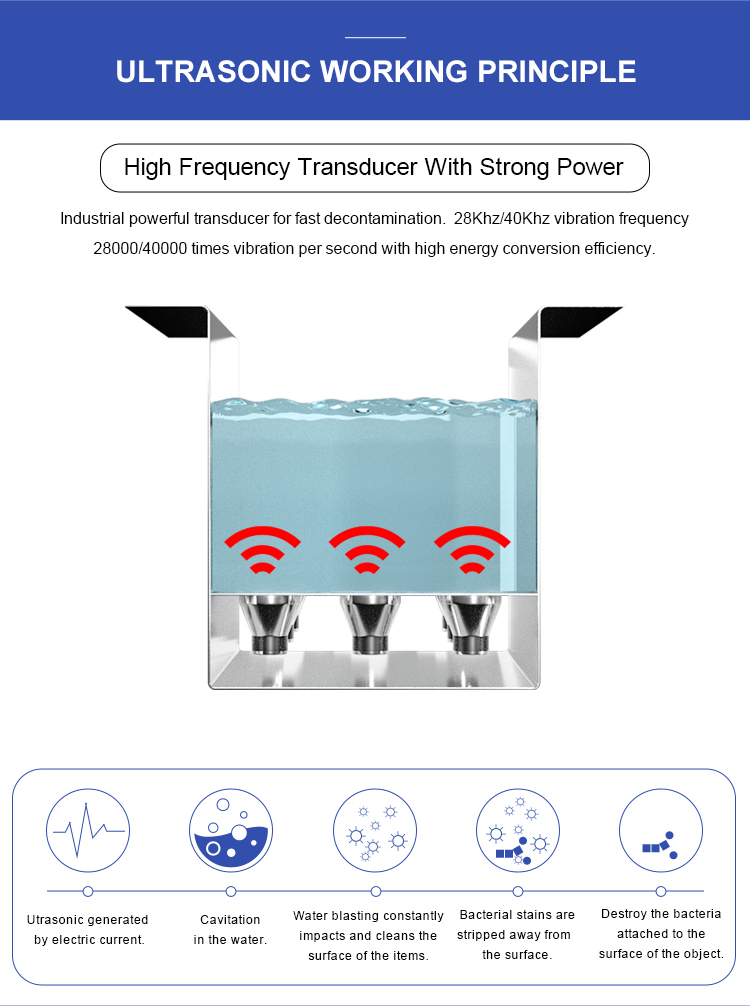

Cleaning Effectiveness: Ultrasonic cleaning is highly effective at removing a wide range of contaminants from hard surfaces. The intense cavitation effect generated by the collapsing bubbles creates powerful scrubbing action, reaching into crevices, blind holes, and other difficult-to-reach areas that traditional cleaning methods might struggle to access.

Non-Destructive: Ultrasonic cleaning is a non-destructive cleaning method for hard surfaces. The energy generated by the collapsing bubbles is localized and focused on the contaminants, minimizing the risk of damage to the object being cleaned. This makes it suitable for delicate and intricate objects such as jewelry, electronics, optical components, and precision instruments.

Versatile Cleaning Applications: Ultrasonic cleaning is used in a wide range of industries and applications. Some common examples include removing grease, oil, and carbon deposits from automotive parts; cleaning jewelry and watches; degreasing and descaling metal components; cleaning surgical instruments and dental equipment; and removing flux residues from circuit boards in electronics manufacturing.

Enhanced Cleaning Efficiency: Ultrasonic cleaning provides enhanced cleaning efficiency compared to traditional methods. The microscopic bubbles created by ultrasonic waves can penetrate tiny crevices and complex geometries, dislodging contaminants that may be difficult to reach using manual scrubbing or other mechanical methods.

Time and Labor Savings: Ultrasonic cleaning can save time and labor compared to manual cleaning methods. It is an automated process where objects are submerged in the cleaning solution and subjected to ultrasonic waves, allowing operators to perform other tasks. Additionally, the scrubbing action of the cavitation effect often reduces the need for manual scrubbing or brushing of the objects.

Environmentally Friendly: Ultrasonic cleaning is generally considered an environmentally friendly cleaning method. It typically uses water-based cleaning solutions or biodegradable detergents, reducing the reliance on harsh chemicals or solvents. Moreover, the process generally requires lower energy consumption compared to other cleaning methods.

Scalability: Ultrasonic cleaning can be easily scaled up or down to accommodate different object sizes and cleaning volumes. Ultrasonic cleaning tanks are available in various sizes, and multiple objects can be cleaned simultaneously, increasing productivity in industrial settings.

Post-Treatment Options: After ultrasonic cleaning, objects may undergo additional post-treatment steps, such as rinsing, drying, or protective coating application, depending on the specific cleaning requirements and desired outcomes.

It's important to note that while ultrasonic cleaning is highly effective for many applications, there may be limitations and specific considerations depending on the object's material, shape, and the type of contaminants involved. It is advisable to review manufacturer guidelines, consult experts, or conduct small-scale trials when implementing ultrasonic cleaning for specific objects or applications.

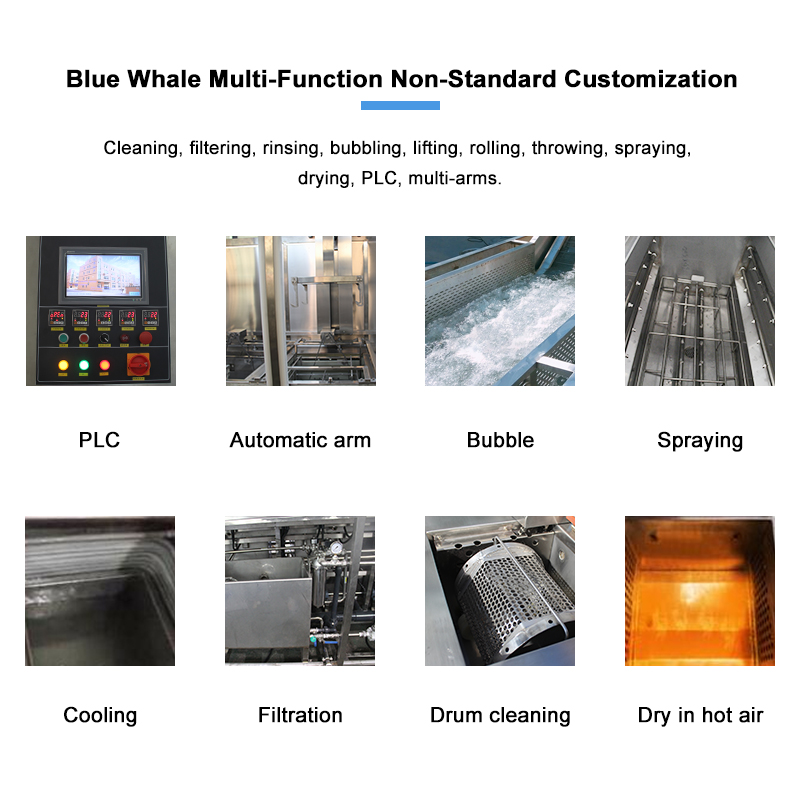

2. Product Features:

1). Working process: the 1st tank ultrasonic cleaning with heating,

remove the rust, grease and dust from the cleaning items. The 2nd

tank high pressure spraying to provide deep cleaning service. The

alarm buzzes once complete the spraying process.

2). The inner tank material: the use of 304 stainless steel,

thickened to 2mm, manual argon welding, strong and durable;

3). Adjustable time: 1-99 minutes/hour adjustable, can be opened

often;

4). Memory function: the device has an independent memory chip, and

there is no need to reset over and over after the time is set;

5). Equipment power cord: the use of industrial thickened power

cord, safe and durable;

6). Industrial grade transducer: the use of industrial shock head,

strong force and good effect, can work 24 hours uninterrupted;

7). Generator control system: independent generator control system,

flexible control, can be set according to the user's cleaning needs

to adjust the ultrasonic power;

8). Heating automatic constant temperature system: 20-95 degrees

adjustable, equipped with stainless steel heating tube, fast

heating speed.

3. Double Tanks Industrial Ultrasonic Cleaner CHS Series:

Ultrasonic Cleaning, Heating, High Pressure Spraying

4. What cleaning agent can be used in industrial ultrasonic cleaning machine?

The choice of cleaning agent for an industrial ultrasonic cleaning machine depends on various factors, including the type of contaminants being removed, the material of the objects being cleaned, and any specific industry or regulatory requirements. Here are some common types of cleaning agents used in industrial ultrasonic cleaning:

Water-Based Detergents: Water-based detergents are widely used in industrial ultrasonic cleaning. They are generally mild, environmentally friendly, and effective at removing common contaminants such as dirt, oil, grease, and general soiling. Water-based detergents are available in various formulations to suit different cleaning applications and can be used for a wide range of materials.

Solvent-Based Cleaners: Solvent-based cleaners are often used when water-based detergents are not effective or compatible with the cleaning requirements. Solvents can remove stubborn contaminants like oils, waxes, adhesives, and certain types of coatings. However, it's important to ensure that the chosen solvent is compatible with the materials being cleaned and that proper safety precautions are followed due to the flammable nature of some solvents.

Alkaline Cleaners: Alkaline cleaners are effective for removing heavy grease, carbon deposits, and baked-on contaminants. They are commonly used in industrial settings, such as automotive or manufacturing, where there is a need to remove tough residues. Alkaline cleaners can be highly caustic, so proper safety precautions and material compatibility checks are essential.

Acidic Cleaners: Acidic cleaners are used for specific applications, such as removing mineral deposits, rust, and scale. These cleaners are effective for materials that can withstand acid, but caution must be exercised as they can be corrosive. Acidic cleaners should be used with appropriate safety measures and material compatibility checks.

Specialty Cleaners: Depending on the industry or specific cleaning requirements, there are specialty cleaners available for ultrasonic cleaning. These may include cleaners designed for specific materials like metals, plastics, glass, or delicate surfaces. Specialty cleaners are formulated to address unique challenges and ensure effective and safe cleaning.

When selecting a cleaning agent for an industrial ultrasonic cleaning machine, it's important to consider factors such as the level of contamination, material compatibility, safety requirements, regulatory compliance, and manufacturer recommendations. Consulting with cleaning agent suppliers, equipment manufacturers, or industry experts can help in identifying the most suitable cleaning agent for your specific cleaning needs.

5. Are there any regulations or guidelines that I should be aware of when selecting a cleaning agent for an industrial ultrasonic cleaning machine?

Yes, there are regulations and guidelines that you should be aware of when selecting a cleaning agent for an industrial ultrasonic cleaning machine. Here are some important considerations:

Occupational Safety and Health Administration (OSHA): OSHA provides regulations and guidelines for workplace safety, including the handling and use of chemicals. Ensure that the cleaning agents you select comply with OSHA standards, particularly regarding hazardous materials, labeling, storage, and employee safety.

Environmental Protection Agency (EPA): The EPA regulates the use and disposal of chemicals to protect the environment. Be aware of any specific regulations or restrictions related to the cleaning agents you intend to use, especially if they contain hazardous substances. Follow proper disposal practices and consider using environmentally friendly cleaning agents when possible.

Material Safety Data Sheets (MSDS): Manufacturers are required to provide Material Safety Data Sheets for their chemical products. These sheets contain important information about the properties, hazards, safe handling, and emergency procedures for the cleaning agents. Review the MSDS for each cleaning agent to ensure you understand the associated risks and necessary safety precautions.

Local Regulations: Depending on your location, there may be additional local or regional regulations governing the use, handling, and disposal of cleaning agents. Familiarize yourself with these regulations to ensure compliance.

Industry-Specific Regulations: Certain industries, such as healthcare, electronics, or food processing, may have specific regulations or guidelines regarding cleaning agents. These regulations may pertain to cleanliness standards, residue limits, or material compatibility. Consult relevant industry associations or regulatory bodies to ensure compliance.

Manufacturer Recommendations: Follow the cleaning agent recommendations provided by the manufacturer of your ultrasonic cleaning machine. They may have specific guidelines or restrictions based on the equipment's design and materials. Deviating from these recommendations could affect cleaning performance, equipment warranty, or safety.

Material Compatibility: Consider the compatibility of the cleaning agent with the materials being cleaned. Some cleaning agents may be too harsh or corrosive for certain materials, leading to damage or degradation. Consult with the cleaning agent supplier or perform compatibility tests to ensure the cleaning agent is suitable for the materials you are cleaning.

It is important to stay informed about regulations and guidelines relevant to your industry and location. Regularly review updates and changes in regulations to ensure ongoing compliance with safety and environmental standards. When in doubt, consult with regulatory authorities, industry experts, or chemical suppliers to ensure you are selecting and using appropriate cleaning agents for your industrial ultrasonic cleaning machine.

6. Can you provide more information on the proper maintenance and cleaning of ultrasonic cleaning equipment?

Proper maintenance and cleaning of ultrasonic cleaning equipment are important to ensure its optimal performance and longevity. Here are some guidelines for maintenance and cleaning:

Regular Inspection: Perform regular visual inspections of the ultrasonic cleaning equipment to check for any signs of damage, wear, or loose connections. Pay attention to the transducers, tank, and electrical components. If any issues are identified, address them promptly.

Cleaning Solution Maintenance: Regularly monitor and maintain the cleaning solution in the ultrasonic tank. Over time, contaminants can accumulate in the solution, reducing its cleaning effectiveness. Replace the solution as needed, following the manufacturer's recommendations or when it becomes visibly dirty or degraded.

Tank Cleaning: Clean the ultrasonic tank periodically to remove any residue or buildup that may affect the cleaning process. Drain the tank and wipe the interior surfaces with a soft cloth or sponge. Avoid using abrasive materials that could damage the tank. If necessary, use a mild detergent or cleaning agent recommended by the manufacturer.

Transducer Maintenance: The transducers are responsible for generating the ultrasonic waves. Keep them clean and free from debris or contaminants that could interfere with their performance. Gently wipe the transducers with a soft cloth or sponge, using a mild cleaning solution if necessary. Avoid excessive force or harsh chemicals that could damage the transducers.

Electrical Safety: Ensure that the electrical components of the ultrasonic cleaning equipment are properly maintained and in good condition. Check the power cords, plugs, and connections regularly for any signs of wear or damage. If any issues are detected, consult a qualified technician for repair or replacement.

Descaling: Over time, mineral deposits or scale may accumulate on the tank and transducers, affecting the efficiency of the ultrasonic cleaning process. Descaling agents specifically designed for ultrasonic cleaning equipment can be used to remove these deposits. Follow the manufacturer's instructions for descaling, as the process may vary depending on the equipment model.

Lubrication: If your ultrasonic cleaning equipment has moving parts or mechanical components, check the manufacturer's guidelines for lubrication requirements. Apply the recommended lubricant to ensure smooth operation and prevent excessive wear or friction.

Calibration: If your ultrasonic cleaning equipment has adjustable settings, such as frequency or power level, it may be necessary to periodically calibrate the equipment to maintain accuracy. Consult the manufacturer's instructions or seek professional assistance for calibration procedures.

User Manual: Refer to the user manual provided by the manufacturer for specific maintenance and cleaning instructions tailored to your ultrasonic cleaning equipment. The manual will provide detailed guidelines on maintenance intervals, recommended cleaning agents, and any specific considerations for your equipment model.

By following these maintenance and cleaning guidelines, you can ensure that your ultrasonic cleaning equipment operates efficiently, delivers optimal cleaning results, and has an extended lifespan.

7. Customer's Cleaning Feedback:

8. Something about Blue Whale Factory.

As a manufacturer, we have our own factory building including several floors of production sites and offices, we have focused on the R&D, manufacturing and sales of ultrasonic cleaning equipment for over 20 years. We are a strong and experienced factory. We are good at benchtop ultrasonic cleaners, industrial ultrasonic machines and customized full-automatic cleaning equipment. We are a technologically mature factory in ultrasonic equipment. Our product warranty period is 1 year. We offer technical support and spare parts for the whole service life.

For more information, please link our company website: https://whalesonic.en.alibaba.com

If you have any interest, please kindly contact us at sales3@bwhalesonic.com or call me at 86-13532782263 or 86-13268501951.