Guangdong Blue Whale Ultrasonic Equipment Co;Ltd |

|

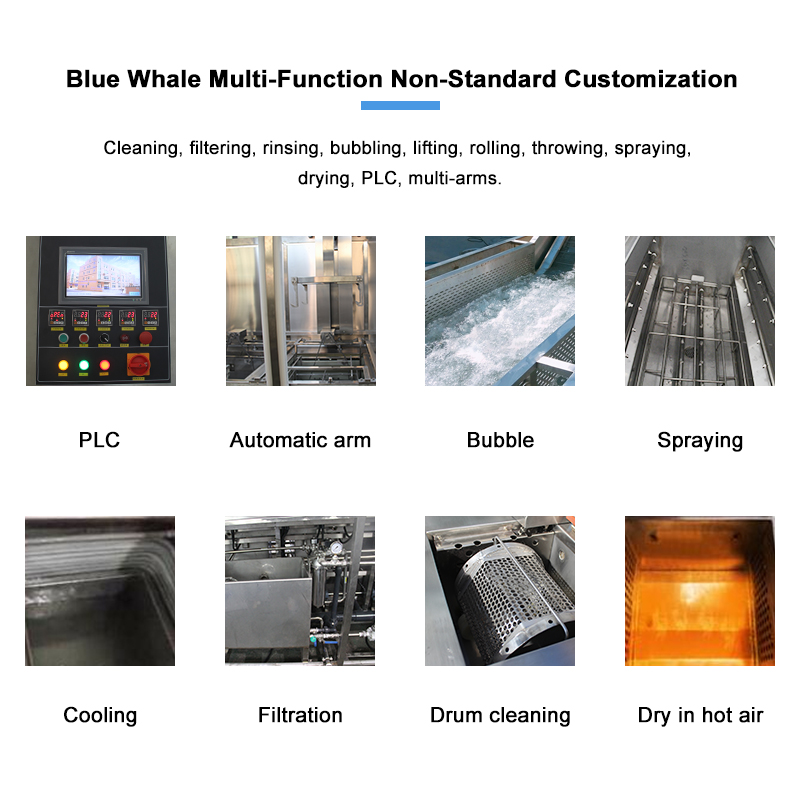

Verified Suppliers

|

|

Blue Whale Two Slots Industrial Ultrasonic Cleaner 53L with Cleaning

Heating Spraying Function to Remove Oil Grease Rust Dust

1. How ultrasonic technology can be used to clean the objects with hard surface?

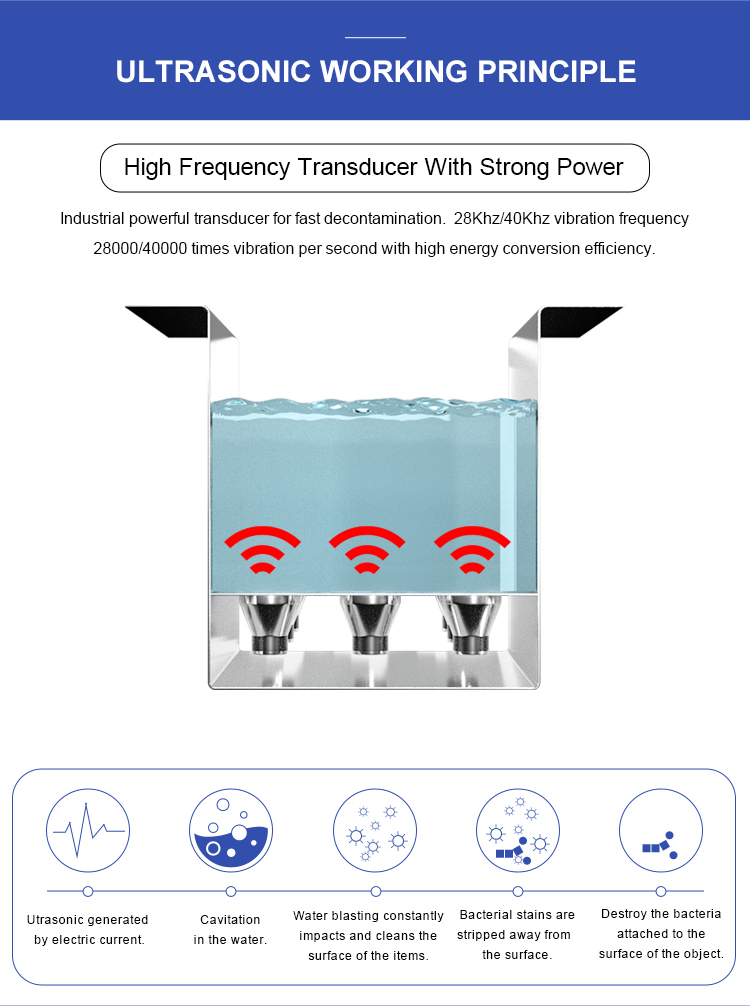

Ultrasonic technology can be used to clean objects with hard surfaces through a process called ultrasonic cleaning. This method utilizes high-frequency sound waves, typically above the range of human hearing, to create tiny, high-energy bubbles in a liquid cleaning solution. When these bubbles collapse near the surface of the object being cleaned, they generate intense localized energy, known as cavitation, which helps to dislodge dirt, grime, and contaminants.

Here's a general overview of how ultrasonic cleaning works:

Equipment Setup: An ultrasonic cleaning system consists of a tank filled with a suitable cleaning solution, an ultrasonic generator that produces high-frequency electrical signals, and ultrasonic transducers mounted on the tank's bottom or sides. The transducers convert the electrical signals into ultrasonic waves.

Object Preparation: The object to be cleaned is placed in the cleaning tank. Depending on the nature of the object and the contaminants involved, it may be necessary to pre-clean or pre-treat the item to remove any loose debris or excessive dirt.

Cleaning Solution: A cleaning solution is added to the tank, often a mixture of water and a specialized cleaning agent appropriate for the specific application. The cleaning solution should be selected based on the type of contaminants to be removed and the material of the object being cleaned.

Ultrasonic Agitation: The ultrasonic generator is activated, and it sends electrical signals to the transducers, which emit high-frequency sound waves into the cleaning solution. These sound waves create alternating high-pressure and low-pressure cycles, causing the formation and collapse of countless microscopic bubbles.

Cavitation Effect: As the sound waves propagate through the cleaning solution, the bubbles form and rapidly collapse near the object's surface. This collapse generates localized energy and creates tiny shockwaves that dislodge contaminants from the object's surface. The process is gentle enough to prevent damage to the object, but powerful enough to remove stubborn dirt and grime even from hard-to-reach areas.

Cleaning Process: The object is submerged in the cleaning solution, and the ultrasonic waves continue to agitate the liquid, ensuring thorough cleaning. The duration of the cleaning process depends on factors such as the type and level of contamination, the object's size, and the power of the ultrasonic system. Typically, cleaning cycles can range from a few minutes to several hours.

Rinse and Drying: After the ultrasonic cleaning cycle is complete, the object is removed from the tank and rinsed with clean water to remove any residual cleaning solution. Depending on the specific requirements, the object may undergo additional processes such as drying, air blowing, or other post-treatment steps.

Ultrasonic cleaning is widely used across various industries, including manufacturing, automotive, electronics, jewelry, healthcare, and more. It is particularly effective for cleaning objects with complex shapes, intricate details, and hard surfaces where traditional cleaning methods may not be as efficient.

2. Product Features:

1). Working process: the 1st tank ultrasonic cleaning with heating,

remove the rust, grease and dust from the cleaning items. The 2nd

tank high pressure spraying to provide deep cleaning service. The

alarm buzzes once complete the spraying process.

2). The inner tank material: the use of 304 stainless steel,

thickened to 2mm, manual argon welding, strong and durable;

3). Adjustable time: 1-99 minutes/hour adjustable, can be opened

often;

4). Memory function: the device has an independent memory chip, and

there is no need to reset over and over after the time is set;

5). Equipment power cord: the use of industrial thickened power

cord, safe and durable;

6). Industrial grade transducer: the use of industrial shock head,

strong force and good effect, can work 24 hours uninterrupted;

7). Generator control system: independent generator control system,

flexible control, can be set according to the user's cleaning needs

to adjust the ultrasonic power;

8). Heating automatic constant temperature system: 20-95 degrees

adjustable, equipped with stainless steel heating tube, fast

heating speed.

3. Double Tanks Industrial Ultrasonic Cleaner CHS Series:

Ultrasonic Cleaning, Heating, High Pressure Spraying

4. Are there any safety precautions that need to be taken when using ultrasonic cleaning?

Yes, there are a few safety precautions that should be taken when using ultrasonic cleaning:

Personal Protective Equipment (PPE): Wear appropriate PPE, such as gloves and safety glasses, to protect your hands and eyes from the cleaning solution and any splashing that may occur during the cleaning process.

Ventilation: Ensure proper ventilation in the cleaning area to prevent the buildup of fumes or vapors from the cleaning solution. This is particularly important if you are using chemical-based cleaning agents.

Chemical Handling: If you are using specialized cleaning agents or chemicals in the ultrasonic cleaning process, follow the manufacturer's instructions for safe handling, storage, and disposal. Some cleaning solutions may be hazardous or require specific precautions.

Electrical Safety: Ensure that the ultrasonic cleaning equipment is properly grounded and the power supply is safely connected. Avoid contact with electrical components while the system is operational.

Temperature Control: Maintain the appropriate temperature range for the cleaning solution, as specified by the manufacturer or process guidelines. Excessive heat can lead to evaporation or degradation of the cleaning solution, while low temperatures may affect the effectiveness of the cleaning process.

Compatibility: Ensure that the object being cleaned is compatible with the ultrasonic cleaning process. Certain materials, such as delicate gemstones, soft plastics, or items with loose components, may be sensitive to the intense agitation caused by ultrasonic cleaning. If in doubt, consult the manufacturer's guidelines or seek professional advice.

Avoidance of Direct Contact: Avoid placing your hands or any body part directly into the cleaning solution while the ultrasonic cleaner is operating. The intense cavitation effect can cause discomfort or injury if there is direct contact with the cleaning solution.

Maintenance and Inspection: Regularly inspect the ultrasonic cleaning equipment for any signs of damage or malfunction. Follow the manufacturer's instructions for maintenance and cleaning of the equipment to ensure its safe and efficient operation.

By following these safety precautions, you can minimize potential risks and ensure a safe working environment when using ultrasonic cleaning technology.

5. What are some common cleaning agents used in ultrasonic cleaning?

Several cleaning agents can be used in ultrasonic cleaning, depending on the specific application and the type of contaminants being removed. Here are some common cleaning agents used in ultrasonic cleaning:

Water-Based Cleaners: Water is often used as a base for ultrasonic cleaning solutions, especially for general-purpose cleaning. It is effective for removing light soils, dust, and some water-soluble contaminants. However, for more stubborn or specific types of contaminants, water alone may not be sufficient.

Detergents: Various types of detergents can be added to the water to enhance the cleaning process. These detergents can help break down oils, greases, and organic residues. They are available in different formulations, such as alkaline, neutral, or acidic, to suit different cleaning requirements.

Solvents: Solvents are used when water-based cleaning agents are not effective or suitable for the contaminants involved. Solvents can dissolve and remove oils, waxes, adhesives, and other non-polar or hydrophobic substances. Common solvents used in ultrasonic cleaning include isopropyl alcohol, acetone, and mineral spirits. It's important to handle solvents with caution, as they may be flammable or have health hazards associated with them.

Surfactants: Surfactants, also known as surface-active agents, are compounds that reduce the surface tension of liquids, allowing the cleaning solution to penetrate and remove contaminants more effectively. They can enhance the wetting and emulsifying capabilities of the cleaning solution, improving its overall cleaning performance.

Enzymatic Cleaners: Enzymatic cleaners contain specific enzymes that break down biological substances such as proteins, blood, and organic matter. They are commonly used in healthcare settings, laboratories, and food processing industries to effectively remove biofilms, stains, and other organic residues.

Rust Inhibitors: For objects susceptible to rust or corrosion, rust inhibitors can be added to the cleaning solution. These inhibitors help protect the object's surface during the cleaning process and prevent or minimize oxidation.

It's important to note that the selection of the cleaning agent should be based on the type of contaminants, the material of the object being cleaned, and any specific requirements or guidelines provided by the manufacturer. It's recommended to consult the manufacturer's recommendations or seek expert advice when choosing the appropriate cleaning agent for your ultrasonic cleaning application.

6. Customer's Cleaning Feedback:

7. Something about Blue Whale Factory.

As a manufacturer, we have our own factory building including several floors of production sites and offices, we have focused on the R&D, manufacturing and sales of ultrasonic cleaning equipment for over 20 years. We are a strong and experienced factory. We are good at benchtop ultrasonic cleaners, industrial ultrasonic machines and customized full-automatic cleaning equipment. We are a technologically mature factory in ultrasonic equipment. Our product warranty period is 1 year. We offer technical support and spare parts for the whole service life.

For more information, please link our company website: https://whalesonic.en.alibaba.com

If you have any interest, please kindly contact us at sales3@bwhalesonic.com or call me at 86-13532782263 or 86-13268501951.