Hubei Nuojin Sen Technology Co.,Ltd |

|

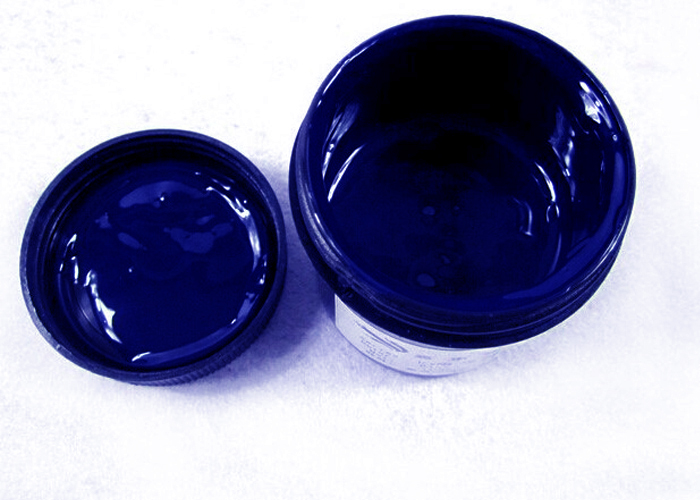

BLUE COLOR PHOTOIMAGEABLE ETCHING AND PLATING RESIST PCB INK

| Items | Technical features | Notes |

| Color | Blue | |

| Viscosity (25℃) | 10±2dPa﹒s | VT-04F |

| Fineness | ≤5µm | 0 ~25µm Fineness gauge |

| Solid content | 50±5% | |

| Density (25℃) | 1.10 ~1.20 g/ml | |

| Resolution | 50µm (2.0mil) | |

| Adhesion | 100/100 | Laceration experiment |

| Plating resistance | Copper ,Tin ,Nickle and Aurum | Normal plating technics |

| Hardness | ≥2H | Pencil harder |

| Etching | Acidic/Alkaline etching solution | |

| Pre-baking limit | 75℃, 60min | |

| Package | 5.0kg/bucket , 20kg/box | According to customer requirements |

| Shelf time | 6 months since the date of manufacture | Store below 25℃ in dark |

Working procedure

| Procedure | Content | |

(1) Pre-treatment | Rinsing and polishing :controlled electric current | |

| Washing :upper pressure 3±0.5 kg/cm2 , nether pressure 2±0.5 kg/cm2 | ||

Microetching :temperature 40±3℃, H2O2/H2SO4/Cu2+→microetching depth 30 ~50 µ inch | ||

| Washing :upper pressure 3±0.5 kg/cm2 , nether pressure 2±0.5 kg/cm2 | ||

| Water-absorbing roller :wetting , no distortion , no impurity | ||

| Drying :85±5℃→ no water trace →water film testing over 30 seconds | ||

| Dust-moving roller :change once every 2 ~4 hours | ||

(2) Printing |

| |

(3) Pre-drying | First side: 75℃×10 ~12min ; second side: 75℃×15 ~18min | |

(4) Exposure | 100 ~180 mJ/cm2 (the effective value through the polyester film), exposure step:7~9 step (standard in the remained film) | |

(5) Developing | Concentration of aqueous Na2CO3 :0.8 ~1.2% | |

| Temperature of developing solution :30 ~32℃ | ||

| Developing pressure:1.2 ~2.0 kg/cm2 | ||

| Developing time:40 ~60 seconds | ||

| Spray pressure after developing :1.6 ~2.0 kg/cm2 | ||

| Washing time:20 ~30 seconds | ||

(6) Plating | Resist to plating Copper ,Tin , Nichel , Aurum | |

(7) Etching | Etching of copper chloride , etching time:40 ~60 seconds | |

| Temperature of etching trough :48 ~52℃ | ||

| Conveyer speed :4.0 ~4.5 m/min | ||

| Spray pressure of etching :1.5 ~2.5 kg/cm2 | ||

| Change once a week of the cloth used for absorbing the oil | ||

(8) Coating-move | Concentration of removing coating solution NaOH:3% ~5% | |

| Temperature of moving coating:45±5℃ | ||

| Time of moving coating:1~2min | ||

| Spray pressure of chemical solution:1.5 ~2.0 kg/ cm2 | ||

Our company:

Company passed the ISO9001 quality standard certification and ISO 14000 environment system certification, which is the national high and new technology enterprise. Company has achieved many honors, including: the Chinese photographic society of professional committee of the radiation curing, deputy director of the unit,the ninth national committee, deputy director of the printed circuit branch of unit, the national standardization technical committee, deputy director of the unit printed circuit boards, printed circuit industry in China in the second session of "nation" brand enterprise, Hubei in 2015 advanced units of ecological construction and environmental protection, etc.Companies always adhere to the science and technology as the first productivity. Enterprise technology center in Wuhan city, the company has built in Wuhan city, and form a complete set of PCB ink research and development of engineering technology research center, two platform, and lead to make the printed circuit with marking ink and the printed circuit using resistance solder "two important industry standards. The company's flagship product, solder resist ink (solder mask) series of products have been American UL safety certification.

Attention :