Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

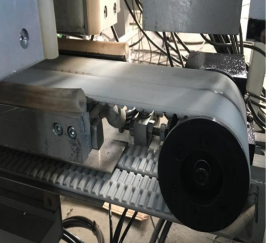

Air float insulating glass production line, the latest technology, to ensure the perfect operation of the new processing

The side of insulating glass should be aligned, and a small opening should be reserved at the back to let the dried gas escape. After pressing, the sealing should be done immediately. The outer part of the aluminum frame and the edge of the glass should have a distance of 5 mm and 7 mm after the completion of the processing of the rubber type insulating glass. It is used for coating the first channel sealing. To make sulfur glue, it should be coated along one side to avoid bubbles. To accomplish this aluminum strip double-glazing glass , the placement of hollow glass processing: hollow glass placed correctly or not will affect the final quality of hollow glass, both in the production, transportation or storage first design for fear of the shadow characteristics of pile frame, heap at the bottom of the frame has certain gradient but plane and side should always maintain 90 degrees, thus can protect hollow glass of two pieces of glass bottom vertically placed outside the pile frame, the ministry of machinery not continent meters and other swimming trapped to empty the first line of sealant will produce different degrees of erosion, thus affecting the sit glass sealing performance

The cleaning of glass must be done by machine, because manual cleaning cannot guarantee the cleaning quality. To ensure the bonding between sealant and broken glass, it is better to use deionized water. In addition, to ensure water circulation and save water resources, the water can be filtered to ensure long-term use. After cleaning the glass to pass the light inspection, check the surface of the glass whether there is water, water stains and other stains, if there is water and other drift with machine speed such as hot product degree. The air lamp, the brush, in addition to the adjustment until the effect is good enough to wash after printing glass should be assembled into hollow glass within 1 hour, in addition to ensure that the glass and glass do not scratch between the best semi-finished glass storage car, the glass separated

| NAME | ORIGIN | BRAND |

| Transfer motor | Germany | SIEMENS |

| Brush motor | Germany | SIEMENS |

| Servo motor | Germany | SIEMENS |

| PLC | Germany | SIEMENS |

| Low voltage electrical appliance | Germany | SIEMENS |

| Frequency converter | Germany | SIEMENS |

| Micro Switch | Taiwan | TEND |

| Button and indicator light | France | SCHNEIDER |

| touch screen | Taiwan | WEINVIEW |

| Intermediate relay | Japan | OMRON |

| Water pump | China | LINGXIAO |

| Guide | Taiwan | HIWIN |

| Pneumatic Components | Taiwan | AIRTAC |

| electric gauge | China | MIRAN |

| Photoelectric switch | Korea | AUTONICS |

| JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD | ||