Sichuan Techairs Co., Ltd |

|

Verified Suppliers

|

|

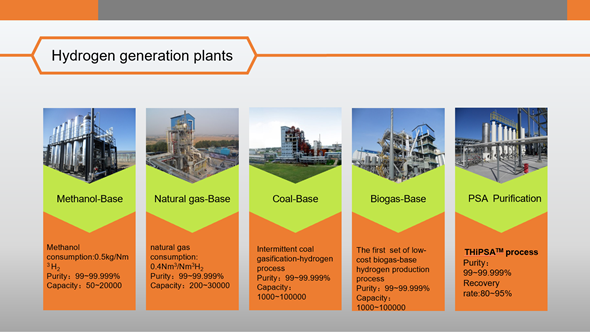

1000Nm3/H Hydrogen Manufacturing Plant PSA Unit For Hydrogen Production

Jiangsu 1000Nm3/h Hydrogen Generation Plant,Hydrogen Production From Methanol

Technology Application

Techairs is professional engaged in gas preparation, separation and

purification technology research and development and engineering

transformation. It is widely used in petrochemical industry, coal

chemical industry, fine chemical industry, gas industry, ethanol

industry, photovoltaic semiconductor industry and PTA

industry.Unique THiPSATM technology and FrTPSA technology can

achieve high purity, high yield, low material consumption and low

energy consumption; Separation of multicomponent gas and low

separation coefficient gas.

Technical indexes

Capacity:1000Nm3/h

Purity:99% ~ 99.9999%

Know how

● “Double high double low” – THiPSATM PSA technology: Gas PSA separation and technologies with high purity and high recovery rate, low material consumption and low energy consumption are used in the gas preparation purification technology and in the purification of trichlorosilane, chloro-silicane, cyclohexanone, cyclohexanol, ethylhexanoate, caprolactam, vinyl chloride, styrene, end gas containing ammonia, chlor-alkali end gas, coke oven gas, blast furnace gas, converter gas, semi-coke end gas and source of gas containing hydrogen, and its materials with heavy constituents shall be recovered.The recovery rate of hydrogen gas is larger than 5% higher than that of conventional PSA.

1.1 What is the THiPSATM recovery of hydrogen purification of the new process?

1) Sino-US joint development and can simultaneously achieve high yield, high purity double high PSA separation technology;

2) THiPSATM new technology is composed of a series of proprietary technology:

a. The ultra-low dead space ratio, large capacity adsorption of new adsorbent

b. Selective polymer membrane and PSA technology effective coupling

c. Low pressure or vacuum adsorption, regeneration of gas back to use

d. Differential pressure, grading, staggered PSA

1.2 Practical Fields of THiPSATM New Process:

1) Gas for hydrogen decomposition: Natural gas/methanol/biogas steam reforming gas, methanol decomposition gas, coal gas

2) Refinery tail gas: Catalytic cracking (FCC) dry gas, hydrocracking low molecular weight dry gas, hydrofinishing, aromatics isomerization hydrogen-rich, catalytic reforming hydrogen

3) Petrochemical exhaust: Lube oil hydrogenation, ethylene flare gas, styrene exhaust, EO/EG emissions

4) Coal chemical industry: coal bed methane, coke oven gas, ammonia/methanol tail gas, chlor-alkali tail gas, biogas....

1.3 Basic Characteristics of THiPSATM New Process:

1) Overcoming thecontradiction between traditional PSA process purity and yield, and realizing recovery and separation with both high yield and high purity;

2) Effective components in the PSA desorbed gas are recycled through THiPSATM new process, and the advantages include:

a. Reducing complex pretreatment in traditional separation techniques;

b. Relatively reducing investment;

c. Reducing PSA regeneration load, avoiding cross-infection between adsorbents, adjusting the matching between adsorption and regeneration;

d. Effectively solving multi-phase PSA regeneration gas circulation accumulation and avoiding the reverse of the adsorption concentration gradient;

e. Suitable for products and exhaust pressure conditions, especially the output of the exhaust pressure can be adjusted;

3) An effective combination of the new adsorbent (TechairsTM) with a ultra-low dead space rate can significantly reduce retention of effective components in dead space, reduce the number of pressure equalization or avoid product hydrogen flushing or even evacuation, in order to realize high yield and high purity;

4) Suitable for feed gas conditions on edge of the effective component range of conventional PSA treatment.

5) Coupling with the multi-phase PSA process is especially good, and realizing sub-phase or sub-concentration of PSA.

Engineering case