Guangdong Hwashi Technology inc. |

|

Verified Suppliers

|

|

HWASHI IBC Metallic Grid Mesh Bending Machine Three-Phase Four Wires 380V

Description Of The IBC Cage Frame Automatic Production Line

The IBC cage frame automatic production line is mainly used to manufacturing the IBC cage frame. It is composed of cage frame automatic welding machine, mesh unloading mechanical arm, turnover table, automatic frame bending machine, locking machine, hole making and punching machine, automatic production line moving mechanical arm. The complete line requires only 3-4 person. Operator only need to do the material loading to the frame welding machine, and do unloading at the end of the line. Also we can equip the line with automatic base frame welding machine and automatic unloading mechanical arm for the base frame.

Running Process Of The IBC Cage Frame Automatic Production Line :

Frame welding——bending——locking——hole punching——unloading——base

frame welding——base frame loading——manual screw for base frame and

outer frame

Description Of The Vertical Double Station IBC Frame Bending Machine

Vertical double station IBC frame bending machine undergoes comprehensive processing to guarantee not only high precision in bending but also stable operations and remarkable efficiency.

The bending machine expertly transforms the flat mesh into a precisely squared frame. Achieving the bending process in approximately 20-25 seconds highlights the machine's efficiency and rapid production capability.

CNC processed bending beam is used to ensure the bending angle.

Each mold on the bending beam can be adjusted upward and downward for about 3mm to increase bending range.

120 degree mold design made each bending angle more smooth.

Vertical Double Station IBC Frame Bending Machine

Technical Parameter of The Vertical Double Station IBC Frame Bending Machine

| Items | Data |

| Bending Method | Four columns bending at the same time |

| Bending Size | 1200+1000mm (tolerance ±5mm) |

| Loading Method | Manual or Automatic |

| Bending Efficiency | 25-30 sec |

| Bending Force | Hydraulic |

| Required Operator Number | Manual: 1 people,Automatic: 0 |

Applications Of The Vertical Double Station IBC Frame Bending Machine:

Mainly used for bending IBC frame.

Sample Of The Vertical Double Station IBC Frame Bending Machine

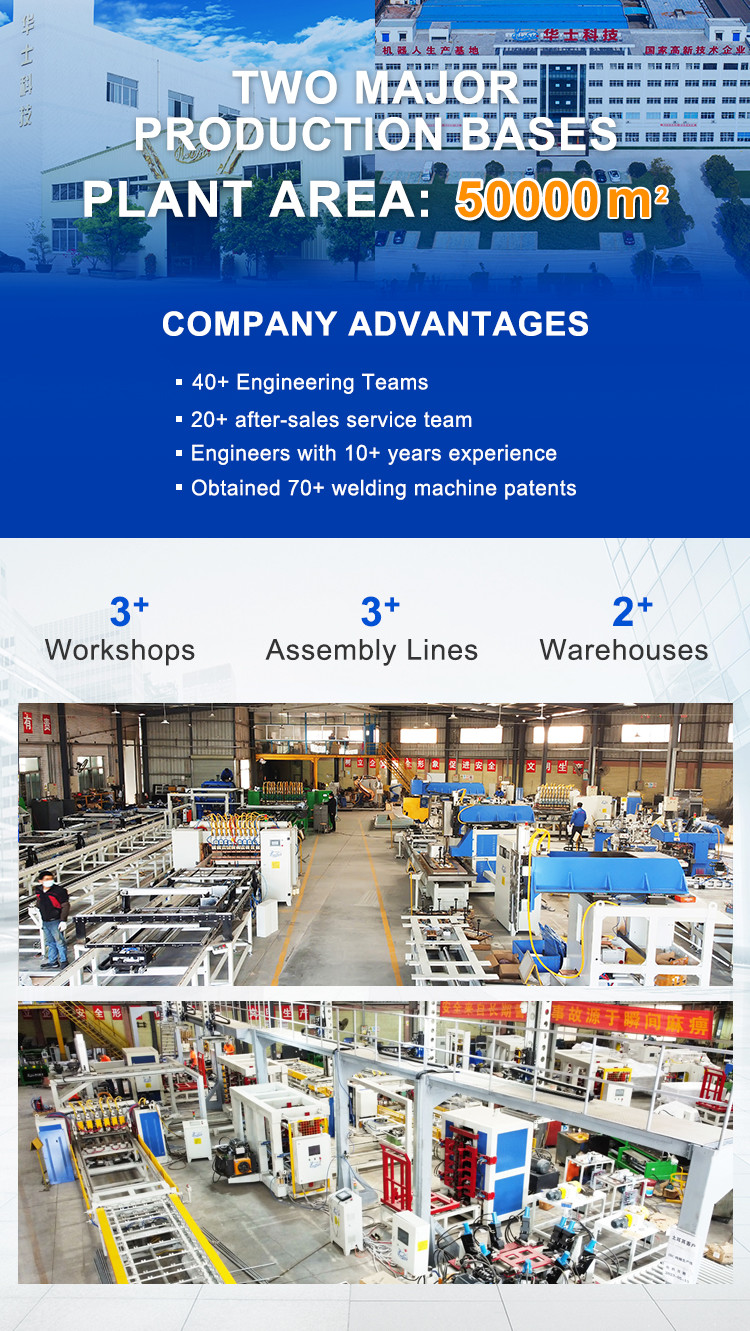

Our Company

Cooperated Customers