Guangdong Hwashi Technology inc. |

|

Verified Suppliers

|

|

HWASHI IBC Cage Frame Production Line IBC Cage Base Frame Welding Machine

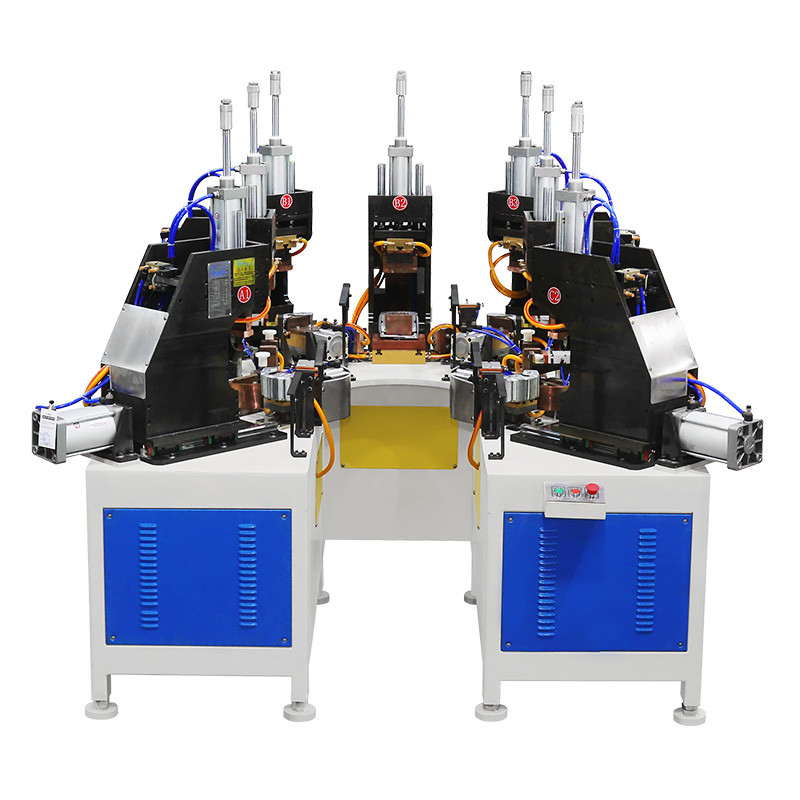

Description Of The IBC Cage Base Frame Welding Machine

The base frame welding machine design adopts horizontal structure

and 7 welding heads for completing the welding of base frame.The

operator only need to load and unload the product. The machine will

do the welding automatically.

Features Of The IBC Cage Base Frame Welding Machine:

1. The design adopts horizontal structure and 7 welding heads for

completing the welding of base frame. The operator only need to

load.

2. Welded pallet will be unload automatically. The machine will do

the welding automatically.

3. It adopts 3 sets of MF DC 250KVA power. The machine helps to

increase product quality and production rate, lower the production

cost.

4. Solve the problem of unstable welding quality caused by manual

work. Higher production rate and automation level.

Applications Of The IBC Cage Base Frame Welding Machine:

Mainly used for bending IBC pipe based frame.

Sample Of The IBC Cage Base Frame Welding Machine

IBC tank welding machine Production line equipment

Description Of The IBC Cage Frame Automatic Production Line

The IBC cage frame automatic production line is mainly used to manufacturing the IBC cage frame. It is composed of cage frame automatic welding machine, mesh unloading mechanical arm, turnover table, automatic frame bending machine, locking machine, hole making and punching machine, automatic production line moving mechanical arm. The complete line requires only 3-4 person. Operator only need to do the material loading to the frame welding machine, and do unloading at the end of the line. Also we can equip the line with automatic base frame welding machine and automatic unloading mechanical arm for the base frame.

| Six-Head IBC Frame Automatic Welding Machine The welding power is designed with 4 sets of MF DC power source. It can do 6 spots welding at one time. Double layer fixture feeder. When one fixture is under welding, another fixture can be loaded with material. | Flat Tube Mesh and Firm Welding Quality The welding machine will weld the tube into flat mesh type. Firm and strong welding quality. It will take about 60sec to complete the welding process. |

| Vertical Double Station IBC Frame Bending Machine IBC cage frame double station bending machine is processed as a whole to ensure high bending precision, stable operation and high efficiency. | Bend the Flat Mesh into Square Shape The bending machine will bend the flat mesh into square frame. It will takes about 20- 25sec to complete the bending process.

|

| IBC Cage Frame Locking Machine IBC cage frame locking machine is processed as a whole, with high insertion precision, large fastness to locking, stable and efficient operation. | Locking Efficiency and Quality

|

| IBC Cage Frame Hole Making and Punching Machine IBC cage frame hole making and punching machine is used to form the hole on the frame, so the complete frame can be fixed on the base frame. | Hole Making Efficiency and Quality The hole making and punching machine is using hydraulic force. It will takes about 25-30sec to complete the complete process. |

| IBC Cage Base Frame Welding Machine The base frame welding machine design adopts horizontal structure and 7 welding heads for completing the welding of base frame. The operator only need to load and unload the product. The machine will do the welding automatically. | Final Product of Base Frame We can add the automatic loading and unloading device for the base frame welding machine as per your requirement. The welding efficiency is about 15-20 sec/pc. |

Technical parameter Of The IBC Cage Base Frame Welding Machine

| Product Name | IBC frame production line | Style | single row /double row |

| Max welding width | 1200mm | Max welding length | 4250mm |

| Brand | Hwashi | Colour | blue/yelllow/custom |

| Equipped Power | 350kVA/400kVA | Place of Product | Zhejiang Province,China |

| Voltage | 3p 380V | Material | Galvanized Pipe |

| Tickness of the pipe | 1-2mm | duty cylce | 20% |

| Diameter of the pipe | 14-20mm | Frequency | 50HZ/60HZ |

| pipe loading method | manual/2 labors | Cable size | ≥70mm3 |

| working capacity | 350-450(480-550) pcs/8 hours | air pipe size | G1 |

| labor demand | 2-3 labors | Water pipe size | G1 1/4 |

Running Process Of The IBC Cage Frame Automatic Production Line:

Frame welding——bending——locking——hole punching——unloading——base

frame welding——base frame loading——manual screw for base frame and

outer frame

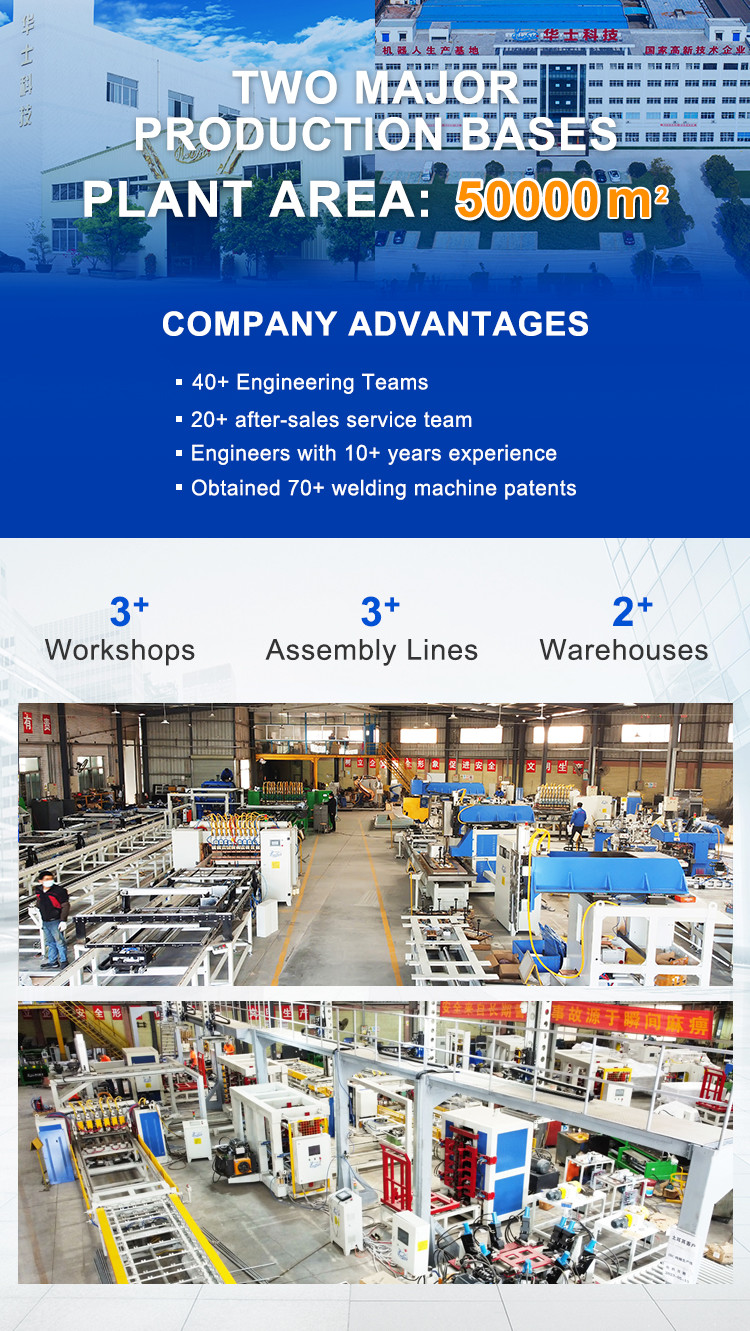

Our Company

Cooperated Customers