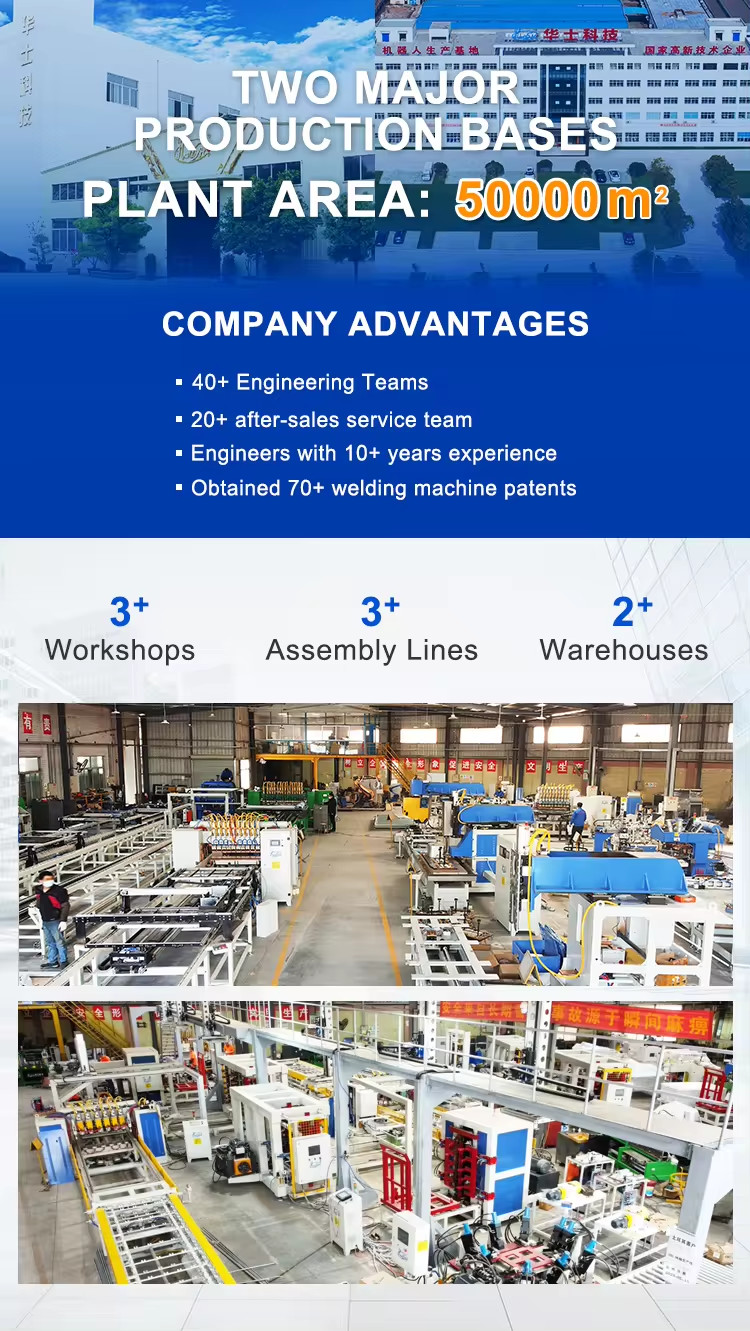

Guangdong Hwashi Technology inc. |

|

Verified Suppliers

|

|

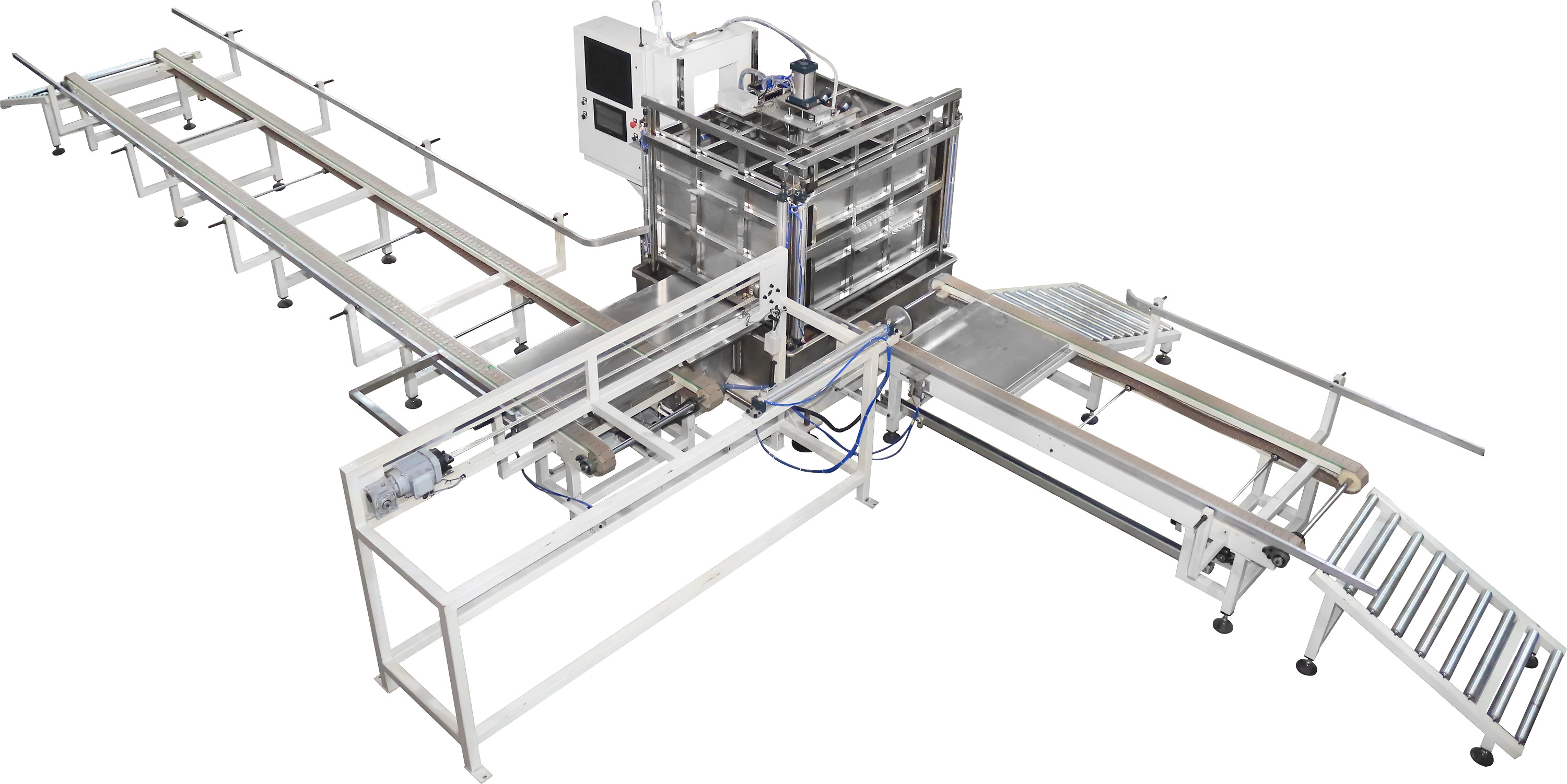

HWASHI IBC Cage Frame Automatic Production Line Machine

Description Of The IBC Cage Frame Automatic Production Line

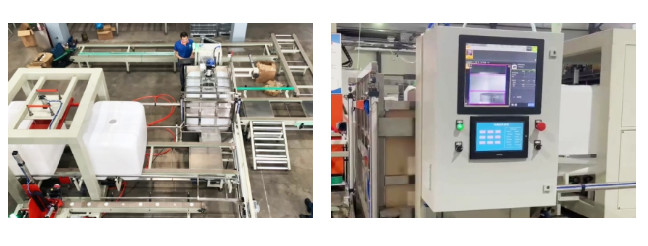

The IBC cage frame automatic production line is mainly used to manufacturing the IBC cage frame. It is composed of cage frame automatic welding machine, mesh unloading mechanical arm, turnover table, automatic frame bending machine, locking machine, hole making and punching machine, automatic production line moving mechanical arm. The complete line requires only 3-4 person. Operator only need to do the material loading to the frame welding machine, and do unloading at the end of the line. Also we can equip the line with automatic base frame welding machine and automatic unloading mechanical arm for the base frame.

Running Process Of The IBC Cage Frame Automatic Production Line :

Frame welding——bending——locking——hole punching——unloading——base frame welding——base frame loading——manual screw for base frame and outer frame

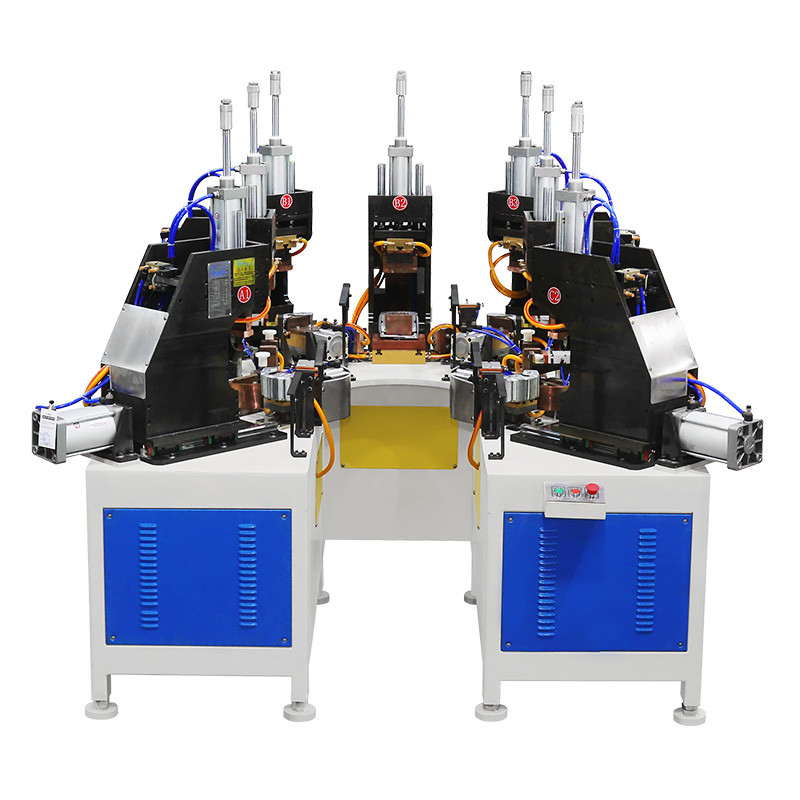

Description Of The IBC Cage Frame Welding Machine

The IBC cage frame welding machine is engineered with precision, featuring four sets of advanced MF DC power sources.

This sophisticated design enables the simultaneous execution of welding at six different spots, showcasing a remarkable capacity for multitasking. Introducing a dual-layer fixture feeder enhances operational efficiency – while one fixture is actively engaged in the welding process, the other can seamlessly load materials, ensuring a continuous and streamlined workflow.

The welding apparatus seamlessly transforms tubes into a distinctive flat mesh configuration, ensuring welds of unparalleled strength and robust quality. The welding process is efficiently completed in approximately 50 seconds, underscoring both speed and precision in the fabrication of each flat mesh.

IBC Cage Base Frame Welding Machine Sample Of IBC Cage Base Frame Welding Machine

Features of The IBC Cage Base Frame Welding Machine

Welding Efficiency: 50sec/pc

Welding Source: 4 sets MF DC Power Source

Feeder Platform Option: Single Layer or Double Layer

Unloading System Option: Manual Unloading or Automatic Mechanical

Arm Unloading

Technical Parameter Of The IBC Frame Automatic Welding Machine

| Items | Data |

| Electricity Requirement | Three-phase Four Wires 380V±10% |

| Electricity Requirement | 400KVA,air switch 600A |

| Control Method | PLC |

| Automatic Moving Speed | 200-500mm/s Adjustable |

| Machine Size | 15600x3000mm(welding machine only) 15600x5000mm(including unloading arm) |

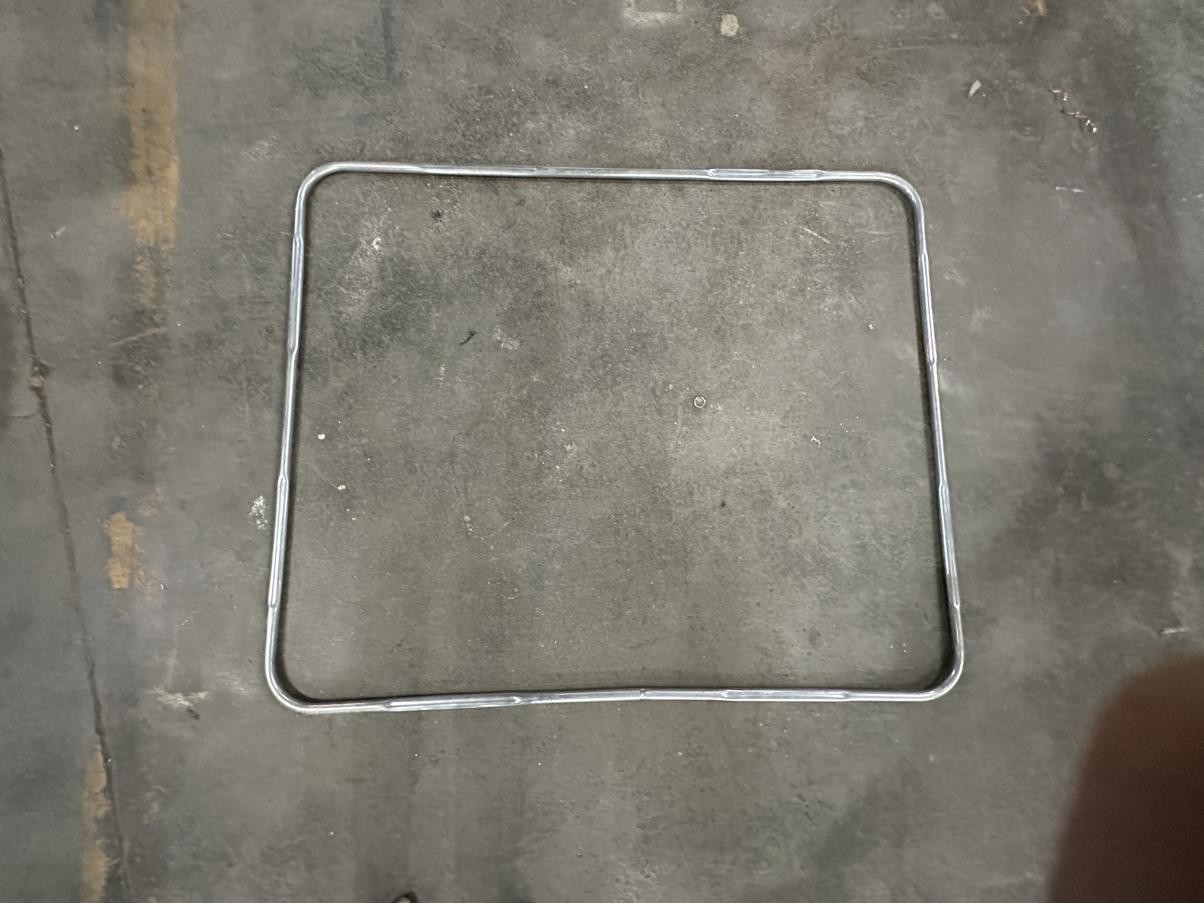

Description Of The Vertical Double Station IBC Frame Bending Machine

Vertical double station IBC frame bending machine undergoes comprehensive processing to guarantee not only high precision in bending but also stable operations and remarkable efficiency.

The bending machine expertly transforms the flat mesh into a precisely squared frame. Achieving the bending process in approximately 20-25 seconds highlights the machine's efficiency and rapid production capability.

CNC processed bending beam is used to ensure the bending angle.

Each mold on the bending beam can be adjusted upward and downward for about 3mm to increase bending range.

120 degree mold design made each bending angle more smooth.

Vertical Double Station IBC Frame Bending Machine Sample Of Vertical Double Station IBC Frame Bending Machine

Technical Parameter of The Vertical Double Station IBC Frame Bending Machine

| Items | Data |

| Bending Method | Four columns bending at the same time |

| Bending Size | 1200+1000mm (tolerance ±5mm) |

| Loading Method | Manual or Automatic |

| Bending Efficiency | 25-30 sec |

| Bending Force | Hydraulic |

| Required Operator Number | Manual: 1 people Automatic: 0 |

Description Of The IBC Cage Frame Locking Machine

The IBC cage frame locking machine is meticulously crafted as a

cohesive unit, boasting exceptional precision in insertion, robust

locking strength, and a seamless blend of stability and efficiency

during operation.

IBC Cage Frame Locking Machine Samples Of IBC Cage Frame Locking Machine

Technical Parameter Of The IBC Cage Frame Locking Machine

| Items | Data |

| Max. Working Height | 1200mm |

| Loading Method | Manual: manual inserting and manual loading Automatic: automatic inserting and loading |

| Lock shape | The outside is round and the inside is backtoothed (customized) |

| Locking Efficiency | 25-30 sec |

| Locking Force | Hydraulic+Pneumatic |

| Required Operator Number | Manual: 1 people Automatic: 0 |

Description Of The IBC Cage Frame Hole Making and Punching Machine

IBC cage frame hole making and punching machine is used to form the hole on the frame, so the complete frame can be fixed on the base frame.

IBC Cage Frame Hole Making and Punching Machine

Samples Of The Frame Hole Making and Punching Machine

Features Of The Frame Hole Making and Punching Machine

The frame hole making and punching machine is using hydraulic

force. It will takes about 25-30sec to complete the complete

process.

1. Pressing heads with pressing mold

2. Hydraulic station

3. Punching head locating panel

Technical Parameter Of The Frame Hole Making and Punching Machine

| Items | Data |

| Max. Working Size | 1200x1000mm (tolerance±5mm) |

| Loading Method | Manual/Automatic |

| Punching Shape | Customized |

| Punching Efficiency | 30-35 sec |

| Punching Force | Hydraulic+Pneumatic |

| Required Operator Number | Manual: 1 people Automatic: 0 |

Description Of The IBC Cage Base Frame Welding Machine

The base frame welding machine design adopts horizontal structure

and 7 welding heads for completing the welding of base frame.The

operator only need to load and unload the product. The machine will

do the welding automatically.

IBC Cage Base Frame Welding Machine Sample of IBC Cage Base Frame Welding Machine

Features Of The IBC Cage Base Frame Welding Machine:

1. The design adopts horizontal structure and 7 welding heads for

completing the welding of base frame. The operator only need to

load.

2. Welded pallet will be unload automatically. The machine will do

the welding automatically.

3. It adopts 3 sets of MF DC 250KVA power. The machine helps to

increase product quality and production rate, lower the production

cost.

4. Solve the problem of unstable welding quality caused by manual

work. Higher production rate and automation level.

Technical parameter Of The IBC Cage Base Frame Welding Machine

| Product Name | IBC frame production line | Style | single row /double row |

| Max welding width | 1200mm | Max welding length | 4250mm |

| Brand | Hwashi | Colour | blue/yelllow/custom |

| Equipped Power | 350kVA/400kVA | Place of Product | Zhejiang Province,China |

| Voltage | 3p 380V | Material | Galvanized Pipe |

| Tickness of the pipe | 1-2mm | duty cylce | 20% |

| Diameter of the pipe | 14-20mm | Frequency | 50HZ/60HZ |

| pipe loading method | manual/2 labors | Cable size | ≥70mm3 |

| working capacity | 350-450(480-550) pcs/8 hours | air pipe size | G1 |

| labor demand | 2-3 labors | Water pipe size | G1 1/4 |

Description Of The Automatic Pipe Bending Machine

Automatic pipe pressing shrinking and double bending for IBC TOTES frame is a special customized machine for IBC base pipe processing. It can achieve full automatic pipe feeding, pipe end shrinking, pipe hydraulic pressing, double head pipe bending, and automatic unloading process. No operator needed. It helps to greatly increase the production rate, and save manpower.

Automatic Pipe Bending Machine Sample Of The Automatic Pipe Bending Machine

Description Of The IBC Tank Leakage Testing Machine

The IBC tank will be delivered to the leakage testing machine by conveyor line. We will use the visual testing and differential pressure detection method to define if the product is qualified or not. The unqualified product will be kicked out of the line automatically. High automation level and high precision of the leakage testing.

IBC Tank Leakage Testing Machine

conveyor line visual testing

Technical Parameter Of The IBC Tank Leakage Testing Machine

| IItem | Technical Parameter |

| Power Requirement | 380V 50H z 12KW |

| Feeding Method | Automatic/Manual |

| Detection Method | Differential pressure detection + visual detection |

| Pressure Source | Air Pressure |

| Detection Efficiency | 55-75s |

The IBC tank vibration testing machine can simulate the test environment by driving the platform to vibrate up and down through the motor. It can place two IBC to simulate the maximum load of 3 Tons.

Vibration Testing Machine

Features Of The Vibration Testing Machine :

1) The up and down vibration simulation test was adopted.

2) The machine adopts man-machine interface+PLC programming control

mode, high degree of automation.

3) You can set testing time and vibration frequency according to

your needs.

Technical Data Of The Vibration Testing Machine :

| Itiems | Technical Data |

| Power Requirement | 380V 50Hz 18KW |

| Motor Power | 15KW |

| Max. Testing Frame Number | 2 pieces (2000kg) |

| Testing Time | 0 to 1 hour |

| Amplitude Range | 25mm±5% |

| Frequency Range | 2-5Hz (100-300 turns/min) |

| Platform Size | 1200x1200mm |

Other Machines Related To IBC Cage Frame Automatic Production Line

Description Of The Long Tube Forming Machine

The long tube forming machine is a special customized machine for IBC tube processing. It can achieve full automatic pipe feeding, pipe end shrinking, pipe hydraulic pressing, and automatic unloading process. No operator needed. It helps to greatly increase the production rate, and save manpower.

Long Tube Forming Machine

Samples Of Long Tube Forming Machine

Technical Parameter Of The Long Tube Forming Machine

| Items | Parameter |

| Pipe Diameter | Round pipe 18mm (customized) |

| Pressing Source | Hydraulic |

| Pressing Mark Number | 20 |

| Shrinking Function | Yes |

| Each Time Processing Number | 2 pcs |

| Efficiency | 12-15sec/2pcs |

Description Of The Short Tube Forming Machine

The short tube automatic forming machine is a special customized machine for IBC tube processing. It can achieve full automatic pipe feeding, pipe end forming and cutting, pipe hydraulic pressing, and automatic unloading process. No operator needed. It helps to greatly increase the production rate, and save manpower.

Short Tube Forming Machine Sample Of The Short Tube Forming Machine

Technical Parameter Short Tube Forming Machine

| Items | Parameter |

| Pipe Diameter | Round pipe 18mm (customized) |

| Pressing Source | Hydraulic |

| Pressing Mark Number | 8 |

| Shrinking Function | Yes |

| Each Time Processing Number | 2 pcs |

| Efficiency | 12-15sec/2pcs |