Beijing Hownew Energy Technology Group Co., Ltd |

|

Verified Suppliers

|

|

Stainless Steel 304 Flange Single Ball Rubber Expansion Joint

1. Expansion joints(compensators)

Expansion joints, also known as compensators, are integral components comprising one or more bellows, connectors, supports, flanges, and conduits. They are installed in flexible structures such as vessel shells or pipelines to counteract additional stresses induced by temperature fluctuations and mechanical vibrations. By harnessing the expansion and contraction of the bellows, they accommodate dimensional changes in pipelines, conduits, vessels, etc., caused by thermal variations or compensate for axial, lateral, and angular displacements. Moreover, they serve purposes like noise and vibration reduction and supporting heating supply systems.

To prevent deformation or damage to heating pipelines from thermal expansion or temperature stress, compensators are crucial to offset the thermal expansion, alleviating stress on pipeline walls and forces on valves or support structures. Renowned for their elastic properties allowing for free expansion and contraction, expansion joints offer reliability, high performance, and compactness, making them prevalent in chemical engineering, metallurgy, nuclear energy, and similar fields.

Expansion joints come in various forms. In vessels, U-shaped expansion joints are predominant, followed by Ω-shaped and C-shaped joints. On pipelines, they are categorized by structural compensation into universal, pressure balanced, hinged, and gimbal expansion joints.

| Main Item | Classification | Description |

| Metal Expansion Joint | ElbowExpansion Joint | Bend the pipe into a U-shaped or other shape, also known as tension bends,are a type of expansion joint that utilizes the elastic deformation ability of the form to compensate. Its advantages are good strength, long service life, and on-site production.The disadvantages are space-consuming, high steel consumption, and high friction resistance. This type of expansion joint is widely used in various steam piping and long pipes. |

Bellows Expansion Joint

| A bellows expansion joint, crafted from metal bellows, facilitates axial expansion and contraction within pipelines, allowing slight bending. To prevent exceeding permissible compensation limits, protective rods or rings are affixed at both ends of the bellows, while guide supports are mounted at either extremity of connected pipelines. Additionally, angular and lateral expansion joints serve to rectify rotational and lateral deformations in pipelines. These expansion joints offer space and material efficiency, along with streamlined standardization and mass production. However, their relatively short lifespan is a notable drawback. Primarily utilized in short pipelines with lower temperature and pressure conditions, advancements in bellows production technology have broadened their application scope. Presently, bellows expansion joints can withstand pressures of up to 6.0 MPa in pipe systems. | |

| Slip-Type Expansion Joint | The slip-type expansion joint consists of inner and outer sleeves capable of relative axial movement. The space between the inner and outer sleeves is sealed with stuffing box. During use, keep both ends of the pipes moving on the same axis. The product mainly consists of sleeves (core tubes), shells, sealing materials, etc. It is used to compensate for axial expansion and axial rotation by arbitrary angle of pipelines. It has the characteristics of small volume and large compensation amount, suitable for hot water, steam, and grease media. By sliding the sleeve against the outer sleeve, it can compensate the thermal expansion. The inner sleeve of the slip-type expansion joint is connected to the pipeline and adopts the principle and structure of high-performance self-sealing dynamic seal. It can slide freely inside the shell with the expansion and contraction of the pipeline, and can meet the sealing requirements of any pipeline. A type of seal with new synthetic material is used between the shell and the inner sleeve, which can withstand high temperatures, possess corrosion resistance, and aging resistance, with an applicable temperature range of -40 to 150 degrees Celsius, and up to 350 degrees Celsius under special circumstances. It can not only ensure axial sliding but also prevent leakage of the medium inside the pipe. | |

| Non-metallic Expansion Joint | Rubber Expansion Joint | Composed of rubber and rubber-fiber composite materials, steel flanges, sleeves, and insulation materials, it is mainly used for flexible connections between various fans and ducts. Its functions include shock absorption, noise reduction, sealing, medium resistance, easy displacement and installation. It is an ideal accessory for shock absorption, noise reduction, smoke and dust removal in the field of environmental protection. |

| Fabric Expansion Joint | The fabric expansion joint is mainly made of fiber fabric, rubber, and other high temperature resistant materials. It can compensate for the vibration and deformation of fans and ducts.Fabric expansion joints can compensate for axial, lateral, and angular products, with features such as no thrust, simplified support design, corrosion resistance, high temperature resistance, noise reduction, vibration reduction,and others.It is particularly suitable for hot blast pipes and smoke and dust pipeline of power plant.The non-metallic compensator's fiber fabric and insulation cotton itself have the functions of sound absorption and vibration isolation, therefore they can effectively reducing the noise and vibration of boiler, fan, and other systems. Simple structure, light weight, and easy maintenance. |

Super Austenitic Stainless Steel:254SMO,904L,AL6XN

Duplex Stainless Steel :2205 Dual phase steel (S31803)

Nickel Based Alloy Steel:INCOLOY800/800H/800HT/840/825,INCONEL600/601/690/625/X-750

Hastelloy Alloy C-276/C-22/X,MONEL400/K500

Pure Nickel:N4,N6(Ni200,Ni201)

Titanium Plate For Stamping:GR1,GR2,TA1,TA2

Austenitic Stainless Steel:SUS304,SUS304L,SUS316,SUS316L,SUS310S,SUS321,SUS316Ti

2. Rubber Expansion Joints

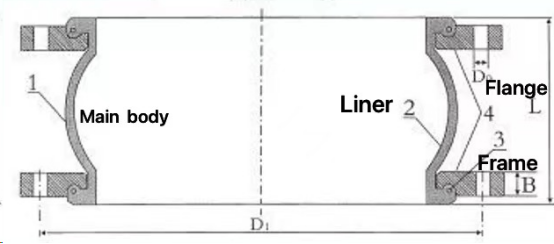

Rubber expansion joints typically feature smooth waveform compensation elements, complemented by rubber flanges at both ends and metal flanges. Employing a loose tube construction, metal flanges are commonly utilized. The compensation element surface comprises rubber, with an inner layer comprising multiple layers of reinforced fiber or steel strip interwoven with wire reinforcement. These reinforced layers extend to the rubber flanges at both ends, with a robust steel wire skeleton housed inside the flanges.

Notably, rubber expansion joints offer substantial displacement compensation capabilities, accommodating axial, lateral, and angular displacements. They possess noise reduction, vibration dampening, and certain corrosion-resistant properties. With attributes such as high-pressure resistance, elasticity, large displacement capacity, effective vibration and noise attenuation, and straightforward installation, they find widespread application across water supply and drainage, HVAC, fire protection, compressor, papermaking, pharmaceutical, marine, pump, and fan pipeline systems.

Selection Instructions

Rubber joints are generally suitable for temperatures ranging from -20°C to 70°C, with the capability to withstand instantaneous temperatures up to 115°C and operate within a range of 70°C to 115°C. In scenarios where flange-connected rubber joints are subjected to high working pressures and temperatures (with diameters exceeding 200 and temperatures surpassing 70°C, while operating pressures exceed 1.5MPa), it's advisable to opt for flange rubber joints equipped with limiting devices.

During the installation of flange-connected rubber joints, ensure that the bolts connecting the flanges are threaded from the inside of the flanges towards both ends, intersecting with washers or spring washers. Tighten the bolts diagonally in a step-by-step manner.

In the case of rubber joints connected via union swivels, it's imperative not to interchange the union swivels at both ends during installation to prevent product leakage or damage.

Rubber expansion joints have ultra-high performance, reliability, and service life, thereby improving factory safety and mechanical integrity of equipment. By inserting specially designed products into rigid pipeline systems, rubber expansion joints can: reduce displacement/improve thermal stability/release thermal changes, load stress, pump pressure fluctuations, system strain caused by sediment wear/ reduce mechanical noise/ compensate for centrifugation/ eliminate electrolysis between different metals.