Force sensor torque transducer |

|

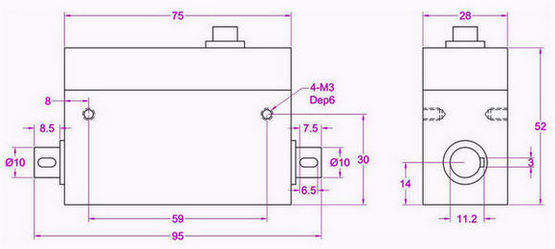

Low Capacity Shaft-to-Shaft Rotary Torque Sensor 0.1Nm 0.2N*m 0.5Nm 1N*m 2Nm 3N-m 5N*m

Shaft to Shaft Low Range Rotary Torque Sensor FY02 is a slip-ring type torque transducer intended for rotating torque measurement in both clockwise and anticlockwise direction,slip rings are used to conduct the millivolt signal from the wheatstone bridge bonded on the sensing shaft which rotates together with motor shaft and gets the torque measured with maximum 0.2% non-linearity of the full capacity. Dynamic torque meter FY02 offers 0-0.1N*m / 0-0.2Nm / 0-0.5N*m / 0-1Nm / 0-2N*m / 0-3N*m / 0-5Nm seven rated measuring ranges to choose from. Keyed shafts located on both ends of the sensor can be connected to motor shaft and load shaft through couplings. Rotating speed of model FY02 goes up to 4000RPM, the housing remains still while the shaft rotates along with the rotating object during measurement. Typical applications for this type of torquemeter are for example servo motor torque measurement, torque control for blenders, test bench applications, screw driver calibration, actuator test,and so on.

| Ordering code | Torque Range | Torque measure direction |

| FY02-0.1NM | 0~0.1N*m | Clockwise & Anticlockwise |

| FY02-0.2NM | 0~0.2N*m | |

| FY02-0.5NM | 0~0.5N*m | |

| FY02-1NM | 0~1N-m | |

| FY02-2NM | 0~2N*m | |

| FY02-3NM | 0~3N*m | |

| FY02-5NM | 0~5N-m |

Specifications

| Rated capacity | 0.1Nm / 0.88lbf*in / 1kg*cm 0.2N*m / 1.77lbf-in / 2kg*cm 0.5N-m / 4.43lbf*in / 5kg-cm 1N*m/ 8.85lb-in / 10kg-cm 2N*m / 17.7lb*in / 20kg*cm 3Nm / 26.5lb*in / 30kg*cm 5Nm / 44.3 lb-in / 50kg*cm | ||

| Rated output | 1.0 mV/V | Compensated temperature | -10...+40oC |

| Excitation | 3-15V | Operating temperature | -20...+60oC |

| Zero balance | ±0.05mV/V | Temperature shift zero | ±0.02% R.O./oC |

| Nonlinearity | ±0.2% R.O. | Temperature shift span | ±0.02% R.O./oC |

| Hysteresis | ±0.2% R.O. | Input resistance | 380±30 ohms |

| Nonrepeatability | ±0.1% R.O. | Output resistance | 350±5 ohms |

| Creep(10min) | ±0.1% R.O. | Insulation resistance | >2000M ohms |

| Safe overload | 150% F.S. | Ingress protection | IP40 |

| Ultimate overload | 200% F.S. | Material of element | Stainless steel |

| Cable | Ø5*3000mm 4-core shielded (Mating connector included) | ||

| Wiring code | Clockwise@ Red--Excitation+ Black--Excitation- Green--Signal+ White--Signal- | ||

A torque sensor is a transducer that converts mechanical torque into mV signal proportional to the applied torque.There are two types of torque transducers: Reaction type torque sensor and rotary type torque sensor. The acting torsion causes deformation of the measuring element,the bonded strain gauge deforms accordingly which will cause the resistance change of the wheatstone bridge,under constant power supply, the output signal between Sig+ and Sig- will change proportionally,thus the moment can be measured by measuring the output signal from the transducer.The output range of dynamic torque sensor FY02 is normally within -15mV...+15mV, a signal conditioner can be used to convert mV signal into -5~5V, 0-10V or 4-20mA output for easy data processing.

Taking rotating torque meter FY02-1Nm working with amplifier FSC(-10-10V)-24V for example,the torque-voltage relationship will be 0-1NM in clockwise direction VS 0-10V output, 0-1N*m in anticlockwise direction VS 0-(-10V) output, 1V output corresponds to 0.1N*m torque in clockwise direction, -5V output corresponds to 0.5N*m torque in anticlockwise direction, and so on.

A Digital readout can also be used to work with our torque

transducers to get below functions:

-Display torque value in real time

-Peak holding to grab the maximum torque during testing

-RS485 or RS232 interface

-0-5V/0-10V/4-20mA analog output

-Switch output for process control

Low Capacity Shaft-to-Shaft Rotating Torque Measurement Transducer 0.1N*m 0.2Nm 0.5N*m 1Nm 2N*m 3N*m 5Nm