Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

Featured selections Trade Assurance Alibaba.com Membership Buyer Central Help Center Get the app Become a supplier High

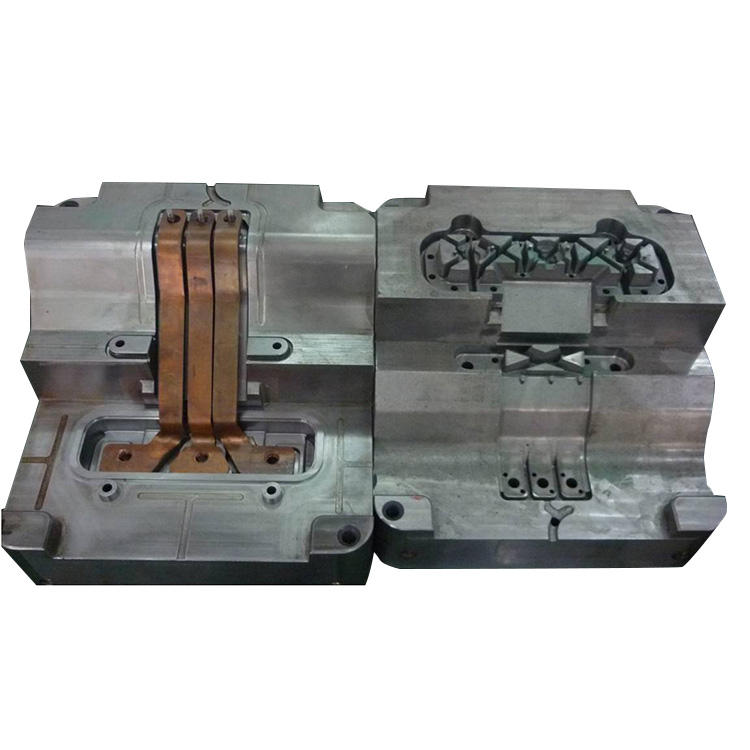

The industrial design landscape is constantly evolving, and with the advent of injection molding, the production of complex and customized components has become more efficient and cost-effective. Among the leading regions in this industrial revolution is China Fujian, where state-of-the-art mold design and manufacturing services are thriving. Our Mold design product is at the forefront of this innovation, offering a comprehensive solution tailored to meet the diverse needs of modern manufacturing.

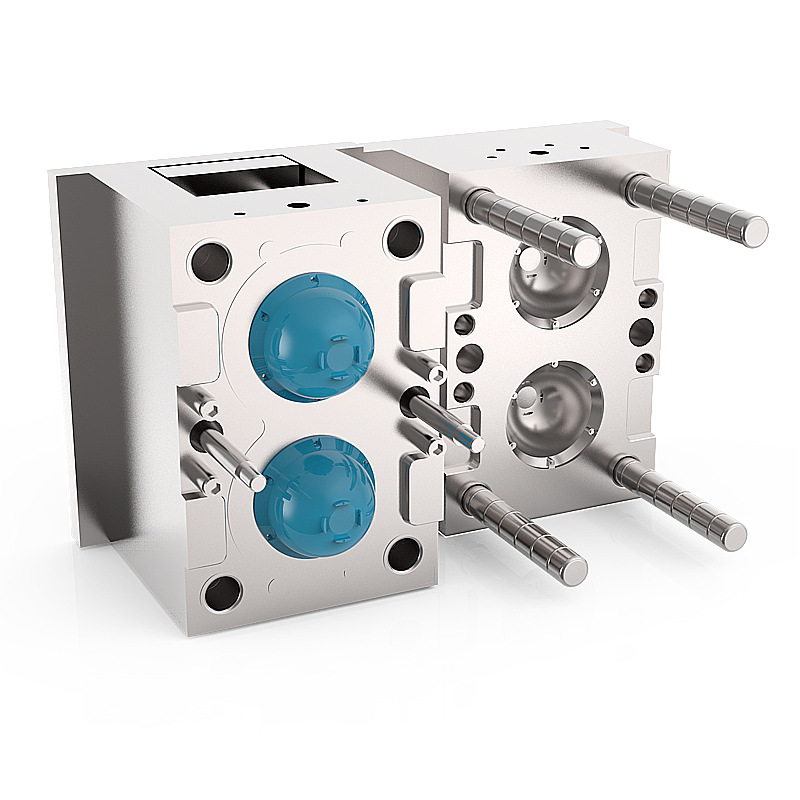

At the core of our services is the design process: Injection Molding. This process is renowned for its precision and versatility, capable of producing high-quality parts with intricate details. Injection molding works by injecting molten material, typically plastic, into a steel mold at high pressure. This technique ensures consistency and repeatability, making it ideal for large-scale production runs where every piece must match the original design specifications exactly.

Our product type caters specifically to industrial design. We understand that in the world of manufacturing, the functionality of a component is as crucial as its design. Our team of skilled engineers and designers works closely with clients to create molds that not only meet aesthetic standards but also adhere to strict industrial requirements. Whether it's a component for a machine, an automotive part, or a medical device, our mold design product ensures that the final output is of the highest quality and ready for use in real-world applications.

The application of our mold design product spans a wide array of manufacturing sectors. We are equipped to handle projects for automotive, aerospace, consumer goods, electronics, and more. The versatility of our mold design product means it can be adapted to various production needs, whether it's a small batch of specialized parts or mass production of standardized components. Our expertise ensures that each mold is optimized for the application it's intended for, resulting in enhanced performance and longevity of the manufactured parts.

Understanding that no two projects are the same, we offer customized mold size options to suit every unique requirement. The customization process begins with a detailed consultation to grasp the scope and specifications of the project. Following this, our engineers design a mold that perfectly fits the dimensions and shapes needed for the client’s product. Whether it's a tiny precision part or a large-scale industrial component, our customized molds are designed for perfect compatibility with the client's manufacturing process.

Material selection is critical in mold making, and that's why we use high-grade steel in our mold design product. Steel offers outstanding durability, resistance to wear, and longevity, attributes that are essential for molds that will be used in high-volume production runs. The use of steel ensures that our molds can withstand the rigors of the injection molding process time and time again, maintaining their precision and ensuring the quality of the end product remains uncompromised.

With a strong focus on quality, precision, and customization, our mold design product is a testament to the craftsmanship and technological advancement of the China Fujian region. By combining traditional mold-making techniques with modern design technologies, we provide a mold design product that meets the growing demands of the manufacturing industry. Trust our expertise to deliver a mold that enhances your production capabilities, reduces lead times, and ensures that your products stand out in a competitive market.

In conclusion, our Mold design product is an embodiment of innovation, designed to cater to the rigorous demands of modern industrial manufacturing. With our customized approach, high-quality materials, and cutting-edge technology, we are committed to providing our clients with a superior mold that not only meets but exceeds their expectations. Embrace the future of manufacturing with our Mold design product, where precision, efficiency, and quality are not just goals but guarantees.

| Attribute | Details |

|---|---|

| Product Type | Industrial Design |

| Mold Life | 100,000-1,000,000 Shots |

| Design Process | Injection Molding |

| Mold Cost | Varies Depending On Complexity |

| Plastic Molding Type | Injection |

| Application | Manufacturing |

| Quality Control | Strict Inspection And Testing |

| Production Volume | Small To Large Scale |

| Design Software | CAD |

| Lead Time | 2-4 Weeks |

Originating from the industrially diverse region of China Fujian, our mold design product stands as a testament to the precision and quality that can be expected from this area. Each mold is meticulously crafted to meet the stringent ISO certification standards, ensuring a consistent level of excellence. Designed primarily for the production of plastic injection mold parts, these molds are engineered to transform raw materials into finely detailed components with utmost accuracy.

With a minimum order quantity of 100 and a competitive price point, our mold design product is accessible for both small startups and large-scale manufacturing companies. We understand the importance of packaging and delivery, which is why each mold is secured in neutral packing, guaranteeing its condition from our facility to yours. The delivery time is set at a standard 30 days, striking a balance between quality assurance and efficient turnaround.

Transactions are conducted with ease, thanks to our straightforward payment terms that require TT (Telegraphic Transfer). This, coupled with a robust supply ability of more than 10,000 pieces every 7 days, ensures that we can meet your production demands consistently, irrespective of the scale. Our commitment to customer satisfaction is further underlined by our after-sales support and the longevity of our molds, which boast a life ranging from 100,000 to a staggering 1,000,000 shots.

The surface finish of each mold is achieved through a careful polishing process that enhances part release and overall aesthetic appeal. This meticulous attention to detail is also evident in our design process, which utilizes injection molding to support both low and high-volume production runs. From small to large scale production volumes, our molds are adaptable to your specific requirements.

Customization is at the core of our service. The mold size can be tailored to fit the unique needs of your project, ensuring that every aspect of the mold design is optimized for your specific application. Whether you are producing intricate plastic injection mold parts or larger components, our molds provide the precision and reliability necessary to maintain a competitive edge in your respective market.

In conclusion, our mold design product from China Fujian is an indispensable tool for businesses looking to produce high-quality plastic injection mold parts. With a fusion of Chinese manufacturing prowess, comprehensive ISO-certified processes, and customer-centric service, we are poised to be your partner in innovation and production excellence.

Place of Origin: China

Certification: ISO

Minimum Order Quantity: 100

Price: Contact us for the latest price

Packaging Details: Neutral Packing

Delivery Time: 30 days

Payment Terms: TT (Telegraphic Transfer)

Supply Ability: 10000+ pcs per month

Lead Time: 2-4 Weeks

Design Process: Injection Molding

Tolerance: ±0.01mm

Mold Cost: Varies Depending On Complexity

Material: High-quality Steel

Product Customization Services: We provide high precision custom mold parts for your unique needs. Our Plastic injection mold parts are designed to meet stringent quality standards. With our advanced technology and expertise, we can manufacture Plastic injection mold parts that are tailored to your specifications.

Our Mold Design product comes with comprehensive technical support and services designed to assist you at every stage of the mold design process. We understand how critical it is to have a reliable support system in place, which is why we offer a range of services to ensure your success.

We provide detailed product documentation that guides you through all features and functions of our Mold Design software. This includes step-by-step tutorials, best practices, and troubleshooting advice to help you overcome any challenges you may encounter.

Our technical support team is made up of experts in mold design and software application. They are available to answer any technical questions you may have, providing you with professional advice and practical solutions.

For more complex issues, our advanced diagnostic services can help identify and resolve problems quickly and efficiently. We use the latest tools and methodologies to analyze your design processes and recommend improvements.

We also offer training services, ranging from basic courses for beginners to advanced workshops for experienced users. Our training programs are designed to enhance your skills and knowledge, ensuring you get the most out of our Mold Design product.

Software updates are regularly provided to ensure compatibility with the latest technologies and to introduce new features that keep your mold design capabilities ahead of the curve. Our update services keep your software current and performing optimally.

Lastly, we have a vibrant community of users where you can share experiences, tips, and best practices. Engage with other professionals in the field to expand your knowledge and collaborate on mold design solutions.

Product Packaging:

Our mold design product is packaged with care to ensure it arrives in perfect condition. Each mold is encased in a protective foam insert that conforms to its unique contours for maximum protection. The foam is then placed inside a sturdy, corrugated cardboard box that can withstand the rigors of transit. We seal the box with heavy-duty packing tape and label it clearly with handling instructions to ensure careful transit.

Shipping:

We ship our mold design products using reputable carriers to guarantee safe and timely delivery. Once your order is processed, we provide you with a tracking number so you can monitor your package's progress. Shipping times vary depending on the destination, but we always aim for the fastest possible delivery. Please note that shipping costs are calculated at checkout based on the weight and dimensions of the package, as well as the shipping destination.

Q1: Where are the molds designed from?

A1: Our mold designs originate from China, where they are meticulously crafted and engineered.

Q2: What certifications do your mold design products have?

A2: Our mold design products are ISO certified, ensuring adherence to industry standards and quality benchmarks.

Q3: What is the minimum order quantity for your mold design products?

A3: The minimum order quantity for our mold design products is 100 units.

Q4: Can you provide the pricing details for your mold design products?

A4: Yes, the price for our mold design products is set at 1 unit of your currency.

Q5: How are the mold design products packaged?

A5: Our mold design products are shipped in Neutral Packing to ensure safe transit and delivery to the customer.

Q6: What is the delivery time for an order?

A6: The standard delivery time for our mold design products is 30 days from the confirmation of the order.

Q7: What are the payment terms for purchasing your mold design products?

A7: We accept payment through TT (Telegraphic Transfer).

Q8: What is the supply ability for your mold design products?

A8: We have the capacity to supply over 10,000 pcs per week for our mold design products.