Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

High quality low price ShenZhen supplier mold maker electric products of plastic injection mould Mold design

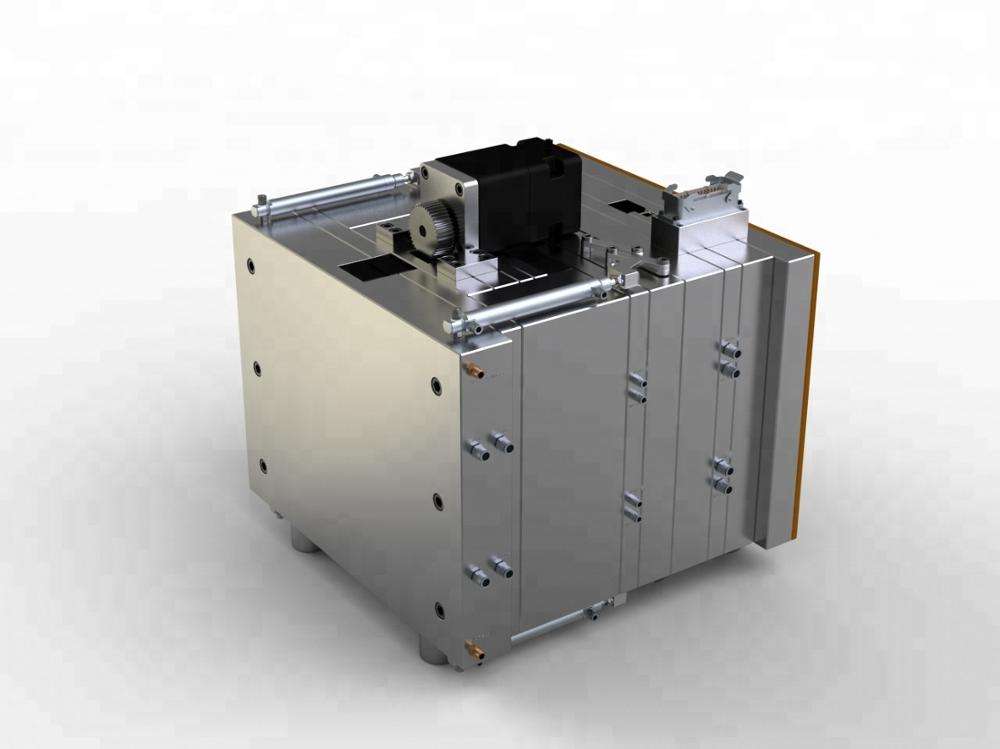

Our Mold Design product, originating from the industrious region of China Fujian, is a premium tooling solution that provides our clients with the flexibility and precision required for their custom mold parts production. With a focus on both single and multiple cavity molds, our product can be tailored to meet a variety of manufacturing needs, ensuring that each mold is optimally designed for the production of high-quality parts, whether in small batches or large-scale production runs.

The cornerstone of our Mold Design product is the stringent quality control process that we adhere to. Each mold undergoes strict inspection and testing to ensure that it meets our high standards and the individual requirements of our clients. This rigorous approach to quality assurance is designed to minimize the potential for defects, reduce the need for costly rework, and ultimately save time and resources for our customers. By choosing our mold design services, you are entrusting your project to a team that is committed to delivering molds of impeccable quality.

Understanding that no two projects are the same, we offer customized mold sizes to accommodate the unique dimensions and specifications of each custom mold part. Our customization service extends to all aspects of the mold design, from the overall size and shape to the intricate details of the mold cavities. This level of customization is crucial for achieving the precise tolerances and fit required for specialized components, ensuring that each part produced meets the exact specifications laid out by our clients.

To facilitate the creation of these highly customized molds, we utilize state-of-the-art design software, specifically CAD (Computer-Aided Design) technology. This allows our skilled designers to construct detailed and accurate mold designs with a high degree of efficiency. CAD software provides the tools necessary to simulate and analyze mold performance before fabrication, allowing for the optimization of the mold design for better part quality and easier manufacturing. Our use of advanced design software is a testament to our commitment to integrating the latest technological advancements into our mold design process.

The choice of material for any mold is critical, and that is why we have chosen to work with high-grade steel in the construction of our molds. Steel is renowned for its durability, strength, and resistance to wear, making it an ideal material for the high demands of injection molding and other molding processes. Our molds are built to withstand the rigors of continuous use, maintaining their precision and reliability over time. By selecting premium steel materials, we ensure that our molds not only meet but exceed the expectations for performance and longevity.

In the competitive world of custom mold parts manufacturing, our Mold Design product stands out as a leader in its class. From the bustling workshops of China Fujian to the global stage, our molds are synonymous with quality, precision, and customization. Whether you are in the market for a single cavity prototype mold or a complex, multi-cavity production mold, our team is equipped to deliver a tailored solution that meets your exact needs. Experience the difference that our meticulous design process, rigorous quality control, and commitment to customer satisfaction can make for your custom mold parts projects.

| Technical Parameter | Description |

|---|---|

| Application | Manufacturing |

| Design Process | Injection Molding |

| Lead Time | 2-4 Weeks |

| Quality Control | Strict Inspection And Testing |

| Plastic Molding Type | Injection |

| Surface Finish | Polishing |

| Cavity Number | Single Or Multiple |

| Design Software | CAD |

| Mold Size | Customized |

| Tolerance | 0.01mm |

The mold design product, originating from the industrious region of China Fujian, is a testament to precision engineering and design excellence. These Plastic injection mold parts are crafted with meticulous attention to detail, adhering to the stringent standards of ISO certification. The mold design product is ideal for manufacturers and industries that require high-quality Mould solutions for their production lines.

With a Minimum Order Quantity of 100 and an affordable price point of 1, our mold design product represents not only quality but also value. Each order is managed with the utmost care, with Packaging Details that ensure Neutral Packing to safeguard the integrity of each component during transit. Clients can expect a Delivery Time of 30 days, a reflection of our commitment to prompt service without compromise on quality.

Our Payment Terms are customer-friendly, accepting TT to facilitate a smooth transaction process. Additionally, we boast a robust Supply Ability of 10000+pc+7, ensuring that we can meet the demands of both small-scale projects and large-volume production requirements. Moreover, our Mould solutions cater to a diverse range of applications and scenarios, thanks to the flexibility in Cavity Number, offering both Single Or Multiple options to accommodate different project scales and complexities.

The Lead Time for our mold design product is set between 2-4 Weeks, ensuring that our clients can progress with their projects in a timely fashion. Each mold is tailored to client specifications, with Mold Size being Customized to fit unique requirements. Our Design Process is centered around Injection Molding, a reliable and efficient method that guarantees the production of high-quality parts.

Lastly, our expertise in Plastic Modling Type is specifically Injection, which is renowned for its precision and versatility. This process is suitable for creating complex and intricate designs, making our Mould solutions perfect for a wide array of applications, ranging from automotive components to consumer electronics and medical devices. In every scenario, our mold design product stands as a pillar of innovation and quality, rooted in the manufacturing excellence of China Fujian.

Place of Origin: China

Certification: ISO

Minimum Order Quantity: 100

Price: Negotiable

Packaging Details: Neutral Packing

Delivery Time: 30 days

Payment Terms: TT (Telegraphic Transfer)

Supply Ability: 10000+ pieces per month

Design Process: Injection Molding

Surface Finish: Polishing

Mold Life: 100,000 to 1,000,000 Shots

Mold Size: Customized

Mold Cost: Varies Depending On Complexity

Our expert team specializes in designing custom mold parts for various applications. With a focus on precision and quality, our mould design services cater to your specific needs, ensuring that the final product meets your exact specifications. Whether you require a simple design or complex custom mould solutions, we have the expertise and technology to deliver exceptional results. Trust us to enhance your project with our tailored product customization services for mold design.

Our Mold Design product comes with comprehensive technical support and services to ensure you achieve the best performance and results. Our support includes access to our online knowledge base, detailed documentation, and a suite of tutorial videos designed to help you get the most out of our product.

If you encounter any technical issues or have questions about how to use any aspect of the Mold Design software, our dedicated support team is ready to assist you. We provide troubleshooting guidance, optimization tips, and best practice advice for a seamless design experience.

We are committed to continually improving our product and services. As part of our technical support, we offer regular software updates including new features, enhancements, and bug fixes to keep your Mold Design software functioning at its best.

Our services also include a user forum where you can connect with other Mold Design professionals. Share your experiences, ask for advice, and gain insights from a community of experts. This collaborative environment can be an invaluable resource as you work to solve complex design challenges.

Please note that our technical support and services are provided during regular business hours and are subject to our terms of service. For any issues that require immediate attention, we strive to respond promptly and effectively to minimize any disruption to your work.

For our Mold Design product, each unit is meticulously packaged to ensure the utmost protection during transit. We use durable, impact-resistant materials tailored to the shape and size of the mold to prevent any damage. The product is first wrapped in a protective foam layer that cushions it against shocks and vibrations.

Once the initial layer of protection is applied, the mold is then placed in a sturdy cardboard box that has been specifically designed to accommodate its dimensions. The box is sealed with heavy-duty packing tape and all seams are reinforced to maintain the integrity of the package during shipping.

To further secure the product, the boxed mold is then placed within a shipping crate made of robust, high-quality wood. This crate is built to withstand the rigors of transport, whether by land, sea, or air. It is securely closed and sealed, with the contents clearly labeled on the outside to facilitate careful handling and delivery to the destination.

Before dispatch, we ensure that all necessary shipping documents are attached and that the package complies with international shipping regulations. The product is shipped with a tracking number, allowing customers to monitor their package's journey until it safely arrives at its final destination.

Q1: What is the origin of the mold design products?

A1: All of our mold design products originate from China, ensuring high-quality manufacturing standards.

Q2: Are the mold design products certified?

A2: Yes, our mold design products come with ISO certification, which denotes international quality and safety standards.

Q3: What is the minimum order quantity for the mold design products?

A3: The minimum order quantity for our mold design products is 100 units, catering to both small and large-scale operations.

Q4: How are the mold design products priced and packaged?

A4: The price for our mold design products is set at 1 unit per price. They are packaged using neutral packing to ensure safe transportation and delivery.

Q5: What are the payment terms and delivery time for the mold design products?

A5: The payment terms for our mold design products are TT (Telegraphic Transfer). The standard delivery time is 30 days after the payment has been processed.

Q6: How is the supply ability for the mold design products?

A6: We have a robust supply ability of over 10000 pieces every 7 days, ensuring a steady supply to meet our customer's demands.