Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

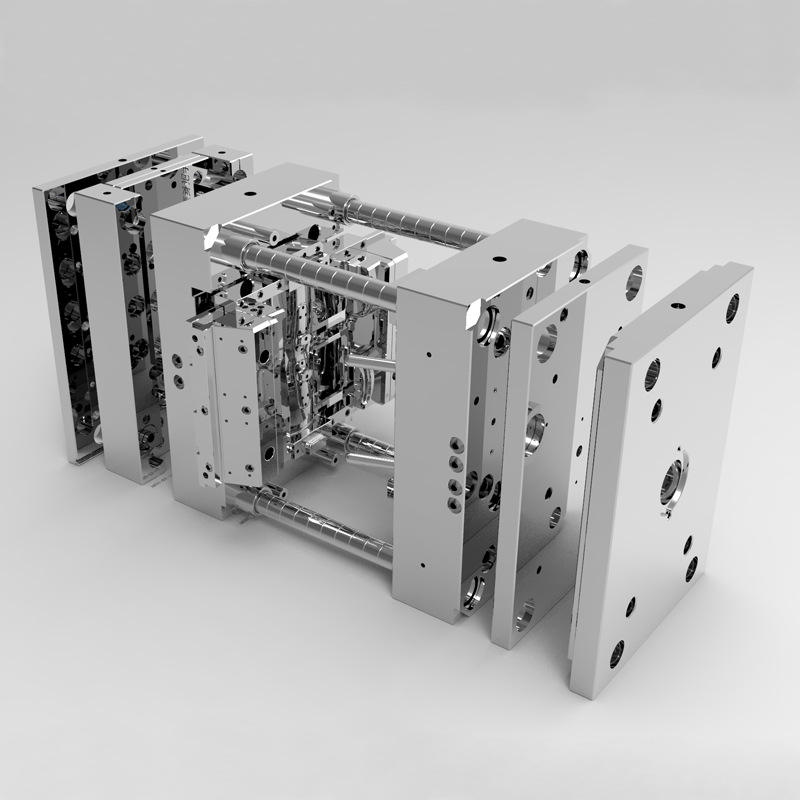

Plastic Injection Mold Maker Custom Plastic Mold Manufacturer Plastic Housing Parts Mould Socket Mold Mold design

The advent of custom mold parts has revolutionized the industrial design sector, allowing for the precise creation of components across a myriad of industries. Our Mold Design Product is a bespoke solution tailored to meet the needs of small to large scale production volumes, ensuring that no project is too big or too small. With a remarkable tolerance of 0.01mm, our mold designs deliver unparalleled accuracy, which is essential for the intricate details required in high-quality industrial components.

Utilizing state-of-the-art Computer-Aided Design (CAD) software, our experienced designers can bring even the most complex ideas to life. This advanced technology enables us to create molds that are not only precise but also efficient in terms of both time and materials. The CAD software's powerful capabilities allow for meticulous planning and modifications, ensuring that the final product is optimized for both performance and production.

Plastic injection mold parts are a cornerstone of our product offerings, catering to a wide range of applications from consumer goods to specialized industrial equipment. Our molds are designed to work seamlessly with plastic injection molding machines, providing a fast and reliable method for mass-producing plastic parts with excellent surface finish and structural integrity. The precision of our molds guarantees that each part produced is consistent, reducing the need for post-production finishing and thus saving on additional costs.

Our commitment to quality does not end with design; we understand that the mold cost is a crucial factor for our clients. Therefore, we offer competitive pricing that varies depending on the complexity of the mold. We work closely with our clients to ensure that the mold design meets their budgetary and functional requirements. Our transparent pricing model ensures that there are no hidden costs, and clients are fully aware of what they are paying for.

The versatility of our mold design product is one of its most compelling attributes. Whether you are looking for custom mold parts for a niche application or need a standard mold for more common plastic injection mold parts, our team is equipped to deliver high-quality results. We take pride in our ability to adapt our designs to any product type within the industrial design space, ensuring that our clients receive molds that are tailor-made for their specific needs.

In the realm of Plastic injection mold parts, durability and reliability are paramount. Our molds are constructed using only the highest-grade materials, designed to withstand the rigors of continuous production without compromising on the quality of the molded parts. This durability translates to a longer lifespan for the mold, offering better return on investment and reduced maintenance costs over time.

To ensure that our clients receive the best possible service, we offer comprehensive support throughout the mold design and manufacturing process. From initial concept to final production, our team of experts is available to provide guidance, answer questions, and make adjustments as required. Our goal is to not just meet but exceed client expectations, delivering a product that adds value to their operations and contributes to their success.

In summary, our Mold Design Product is an exceptional tool for anyone in need of high-precision, custom mold parts or standard plastic injection mold parts. With our small to large scale production capabilities, tight tolerance levels, advanced CAD software, variable mold cost, and dedication to industrial design, we are confident that our molds will serve as a cornerstone for your manufacturing needs. Partner with us and experience the benefits of precision engineering and dedicated customer service in the creation of your next industrial masterpiece.

| Attribute | Details |

|---|---|

| Surface Finish | Polishing |

| Material | Steel |

| Lead Time | 2-4 Weeks |

| Cavity Number | Single Or Multiple |

| Plastic Molding Type | Injection |

| Product Type | Industrial Design |

| Quality Control | Strict Inspection And Testing |

| Production Volume | Small To Large Scale |

| Design Software | CAD |

| Mold Life | 100,000-1,000,000 Shots |

The product in question is a high-precision mold design originating from China, specifically from the Fujian region. This product is designed to cater to various application occasions and scenarios, particularly in industries that require plastic injection mold parts and custom mold parts. The molds are crafted with meticulous attention to detail, ensuring a tolerance of 0.01mm, which makes them suitable for the most demanding manufacturing requirements.

These mold design products come with an ISO certification, guaranteeing international standards of quality and reliability. Whether clients are involved in the automotive, medical, consumer electronics, or packaging industries, these custom mold parts are engineered to meet the specific needs of their production lines. The molds can be designed with a single cavity or multiple cavities, depending on the client's requirements, and are subject to strict inspection and testing to ensure the highest quality control.

For businesses looking to place an order, the minimum order quantity is set at 100 pieces, with each unit priced at 1. To facilitate a smooth transaction, the packaging details are clear – products are delivered in neutral packing to maintain the integrity of the molds during transit. Furthermore, the delivery time is set at 30 days, with a lead time of 2-4 weeks, allowing for efficient planning and integration into the client's manufacturing process.

Payment for these molds is streamlined through TT (Telegraphic Transfer), providing a secure and convenient method for international trade. The supply ability of these products is robust, with the capacity to produce over 10,000 pieces per 7 days, ensuring that even large orders can be fulfilled without delay. The combination of expert craftsmanship, rigorous quality control, and efficient service makes these mold design products from China Fujian an essential asset for any business requiring precision plastic injection mold parts and custom mold parts.

Place of Origin: China

Certification: ISO

Minimum Order Quantity: 100

Price: 1

Packaging Details: Neutral Packing

Delivery Time: 30

Payment Terms: TT

Supply Ability: 10000+pc+7

Cavity Number: Single Or Multiple

Plastic Modling Type: Injection

Application: Manufacturing

Quality Control: Strict Inspection And Testing

Lead Time: 2-4 Weeks

We offer customized Product Customization Services for your Mould design needs, specializing in Plastic injection mold parts . Each mold is crafted with precision and quality control, ensuring that your Plastic injection mold parts meet the highest standards.

Our Mold Design product is supported by a comprehensive suite of technical support and services designed to ensure that you can make the most of our software. Our support includes detailed documentation, an online knowledge base, user forums, and troubleshooting guides to help you solve common issues.

We also offer a range of services to enhance your experience with our Mold Design product. This includes professional training programs, which can be customized to your specific needs and skill level. Additionally, we have a team of experienced technical support engineers who can provide assistance with more complex issues or with optimizing your mold designs for production.

For users looking to maximize productivity, our premium services offer priority support, which includes faster response times and direct access to senior engineers. Furthermore, we conduct regular webinars and workshops to keep you updated on the latest features and best practices in mold design.

To ensure your ongoing success, our support and services are continually updated to reflect the latest advancements in mold design technology and industry trends. We are committed to providing you with the tools and knowledge you need to excel in your mold design projects.

Product Packaging:

Our Mold Design products are meticulously packed in high-quality, durable materials to ensure they reach you in perfect condition. Each mold is securely encased in a custom-fitted foam insert that prevents movement during transit. The foam is then placed inside a sturdy cardboard box, which is sealed and reinforced to prevent any damage from external pressure or impact.

Shipping Information:

Once your Mold Design product is packaged, it is shipped using our trusted courier services to provide you with a fast and reliable delivery. You will receive a tracking number to monitor your package's progress. Please ensure that the shipping address provided is accurate to avoid any delays. Our standard shipping times vary depending on your location, but we strive to deliver within the estimated timeframe.

Q1: Where is the Mold design product manufactured?

A1: The Mold design product is manufactured in China.

Q2: Does the Mold design product have any certification?

A2: Yes, the Mold design product is ISO certified.

Q3: What is the minimum order quantity for the Mold design product?

A3: The minimum order quantity for the Mold design product is 100 units.

Q4: How is the Mold design product packaged?

A4: The Mold design product is packaged using neutral packing to ensure safety and integrity during transit.

Q5: What is the delivery time for the Mold design product?

A5: The delivery time for the Mold design product is approximately 30 days after the order is confirmed.

Q6: What are the payment terms for purchasing the Mold design product?

A6: The payment terms for purchasing the Mold design product are TT (Telegraphic Transfer).

Q7: What is the supply ability for the Mold design product?

A7: The supply ability for the Mold design product is over 10,000 pieces every 7 days.