Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

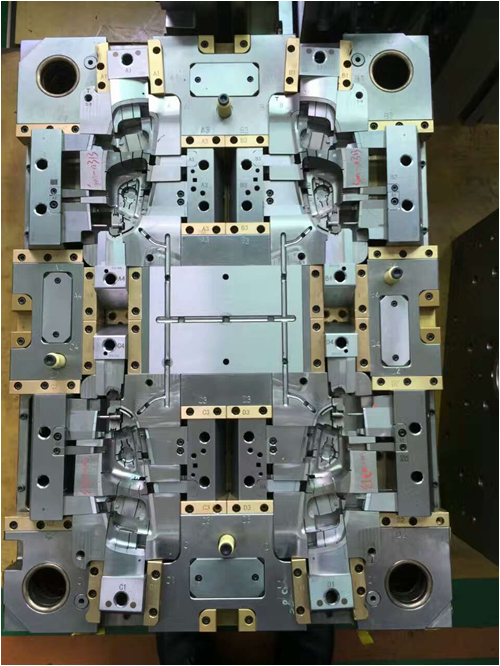

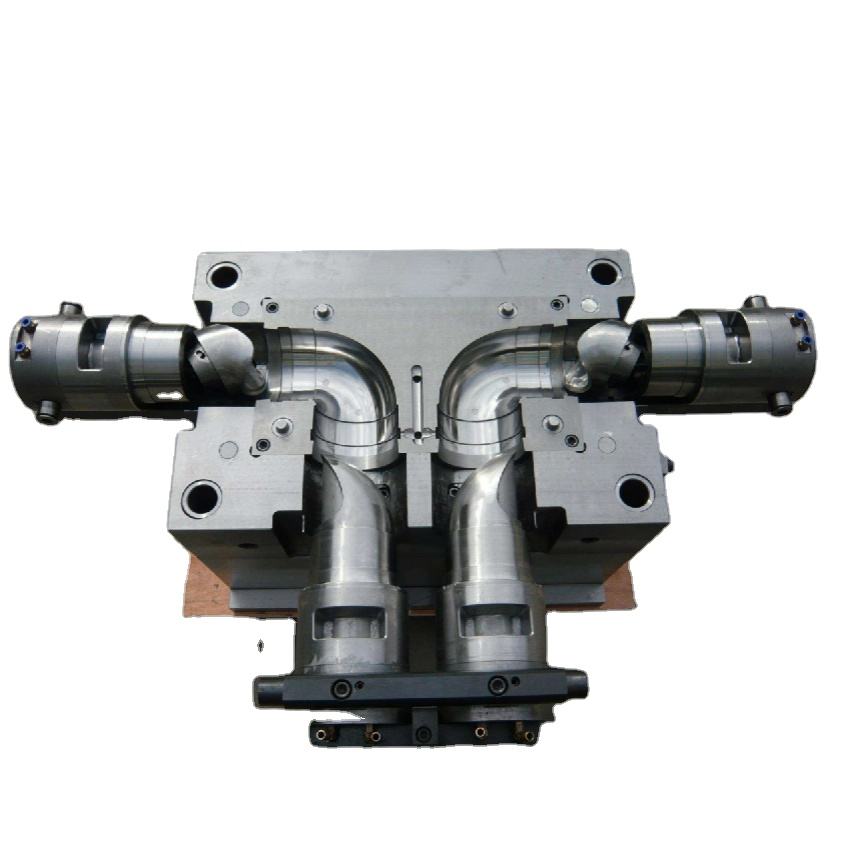

Custom processing service products production shell injection mold Plastic injection mouldingMold making

Our state-of-the-art mold making product is an exemplar of precision and quality in the field of mold design and fabrication. Crafted with meticulous attention to detail, this product offers a high degree of precision that professionals in the industry have come to expect. Perfect for creating detailed and complex designs, our mold making solution ensures that every nuance of your mould design is captured accurately, resulting in a final product that meets the highest standards of excellence.

The material of choice for our mold making product is a high-grade silicone that exhibits an impressive level of flexibility. This flexibility is crucial in mould fabrication, as it allows for the easy demolding of finished parts without risking damage to either the part or the mold itself. The inherent pliability of our silicone material ensures that even the most intricate designs with undercuts can be realized without complications, thereby expanding the creative possibilities for designers and engineers alike.

Alongside its flexibility, our silicone mold making product boasts strong chemical resistance. This resilience against various chemicals ensures a long service life and consistent performance, even when exposed to aggressive resins and other reactive substances commonly used in mold making processes. Whether you are working with epoxies, polyurethanes, or other casting materials, you can be confident that our product will maintain its integrity and continue to produce flawless replicas time and time again.

In the realm of surface finish, our product truly excels. It is engineered to yield a smooth surface finish that enhances the aesthetics and functionality of the final cast pieces. A smooth finish is not only visually appealing but also minimizes the need for post-processing, saving time and resources in the production cycle. This level of surface finish precision ensures that even the finest details are accurately captured, reflecting the true intention of your mould design.

The combination of high precision, strong chemical resistance, smooth surface finish, and flexibility makes our silicone mold making product an indispensable asset in a variety of applications. Whether you are involved in prototype development, small-batch production, or large-scale manufacturing, our product delivers consistent results that uphold the integrity of your original design. It is the ideal choice for professionals who demand nothing less than the best in mould design and mould fabrication.

Our commitment to quality and performance extends beyond the product itself. We understand that successful mold making is a synergy of superior materials and expert design. As such, we offer comprehensive support to ensure that our clients can fully leverage the capabilities of our product. From initial mould design to the final stages of mould fabrication, our team of experts is available to provide guidance and technical assistance to help you achieve exceptional outcomes every time.

In conclusion, for those seeking a mold making solution that embodies precision, durability, and superior finish, look no further than our silicone mold making product. It is specifically formulated to meet the rigorous demands of modern mould design and fabrication, providing an unmatched level of performance that professionals in the industry can rely on. Experience the perfect blend of flexibility, chemical resistance, and a smooth surface finish that will bring your creative visions to life with unparalleled accuracy and quality.

| Attribute | Description |

|---|---|

| Usage | For Creating Molds |

| Durability | High |

| Precision | High |

| Chemical Resistance | Strong |

| Material | Silicone |

| Shelf Life | Long |

| Color | Clear |

| Size | Various Sizes |

| Flexibility | Flexible |

| Surface Finish | Smooth |

The mold making product originating from China has been crafted with precision and is suitable for a variety of applications and scenarios where high-quality molds are required. This product is backed by ISO certification, ensuring that it complies with international standards for quality and safety. With a minimum order quantity of 50 and a competitive price, this mold making product is accessible to both small and large-scale operations.

The product is designed with strong chemical resistance, allowing it to withstand harsh substances that it might come into contact with during the molding process. This makes it ideal for industries where chemical exposure is a common occurrence, ensuring the longevity and durability of the molds created. The fast curing time of the material increases productivity by allowing for quicker turnaround times from mold creation to final product output.

Packaging details are given careful consideration, with neutral packing being utilized to ensure that the product arrives in perfect condition, ready for immediate use. With a delivery time of 30 days and payment terms that include TT, purchasing and planning for the use of this mold making product is straightforward and hassle-free. The supply ability of over 100 pieces every 7 days signifies that even large orders can be accommodated and fulfilled without delay.

The use of this product in mould manufacturing is expansive, catering to various industries that require the high precision it offers. It is beneficial for patternmaking, where exact replicas are paramount, and for mould design, where the intricate details and high temperature resistance are critical. The high temperature resistance ensures that the molds can withstand extreme conditions without losing their shape or accuracy, which is crucial for maintaining the integrity of the cast or formed items.

This mold making product is an essential tool for professionals in various fields such as automotive, aerospace, consumer goods, and medical device manufacturing. The capacity to create detailed and precise molds ensures that the final products meet stringent quality requirements. Whether you are involved in the development of prototypes or mass production, this product provides the reliability and performance needed to achieve outstanding results in mold making.

Place of Origin: China

Certification: ISO

Minimum Order Quantity: 50

Price: 1

Packaging Details: Neutral Packing

Delivery Time: 30 days

Payment Terms: TT

Supply Ability: 100+ pcs every 7 days

Usage: For Creating Molds

Chemical Resistance: Strong

Size: Various Sizes

Temperature Resistance: High

Curing Time: Fast

Specializing in Mould Design , our product customization services cater to your specific patternmaking needs. We ensure top-quality Mould Fabrication with a strong emphasis on chemical and temperature resistance, suitable for various applications in the mold-making industry.

Thank you for choosing our mold making products. We are committed to providing you with high-quality support and services to ensure your complete satisfaction. If you encounter any issues or have any questions regarding our products, please refer to the following technical support and services we offer:

Product Documentation: Comprehensive user manuals and product guides are available for download from our website. These documents provide detailed instructions on product usage, safety guidelines, and troubleshooting tips.

Online Resources: Access our online knowledge base and FAQs for quick answers to common questions and problems. Our online resources are regularly updated to include the latest information and solutions.

Technical Support Forums: Join our community forums where you can connect with other users, share experiences, and get advice from our product experts. Our forums are moderated by technical support staff who can provide additional guidance.

Training and Workshops: We offer a variety of training sessions and workshops designed to help you get the most out of our mold making products. These sessions range from beginner to advanced levels and cover various aspects of mold design and fabrication.

Maintenance and Repairs: Our service centers provide professional maintenance and repair services to ensure your product operates at peak performance. Regular maintenance can help prolong the life of your product and prevent common issues.

Software and Firmware Updates: Keep your product up-to-date with the latest software and firmware updates available from our website. These updates can improve functionality, add new features, and enhance overall performance.

We are dedicated to providing exceptional support and services to assist you with any needs you may have with our mold making products. Our support team is well-equipped to handle any inquiries and ensure that you have a positive experience with our solutions.

Product Packaging:

Our mold-making products are carefully packaged in sturdy, eco-friendly materials designed to protect the contents during transit. Each item is securely enclosed within a custom-fit packaging that prevents movement and reduces the risk of damage. The outer surface of the packaging is clearly labeled with the product name, handling instructions, and a barcode for efficient tracking.

Shipping:

We ship our mold-making products globally using reputable courier services to ensure timely and safe delivery to your doorstep. Tracking information will be provided upon dispatch so you can monitor your shipment's progress. Please note that shipping times may vary based on your location and customs clearance procedures. We recommend checking the estimated delivery date provided at checkout for the most accurate information.

Q1: Where are these mold making products manufactured?

A1: Our mold making products are manufactured in China, adhering to high-quality standards and industry regulations.

Q2: Do these mold making products come with any certification?

A2: Yes, our mold making products come with ISO certification, ensuring they meet international quality and safety standards.

Q3: What is the minimum order quantity for these mold making products?

A3: The minimum order quantity for our mold making products is 50 units, allowing us to cater to both small and large-scale production needs.

Q4: What is the price of each mold making product?

A4: The price for each mold making product is set at 1. This competitive pricing is aimed at providing cost-effective solutions for our clients.

Q5: Can you provide details about the packaging and delivery of the mold making products?

A5: Certainly, all our mold making products are shipped using Neutral Packing to ensure safe and secure transportation. The delivery time for an order is approximately 30 days after the confirmation of payment.

Q6: What are the payment terms for purchasing these mold making products?

A6: We accept payment through TT (Telegraphic Transfer), which is a secure and efficient way to process transactions for our customers.

Q7: What is the supply ability of your company for these mold making products?

A7: Our company has a robust supply ability, capable of providing 100+ pieces every 7 days to meet the demands of our diverse clientele.