Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

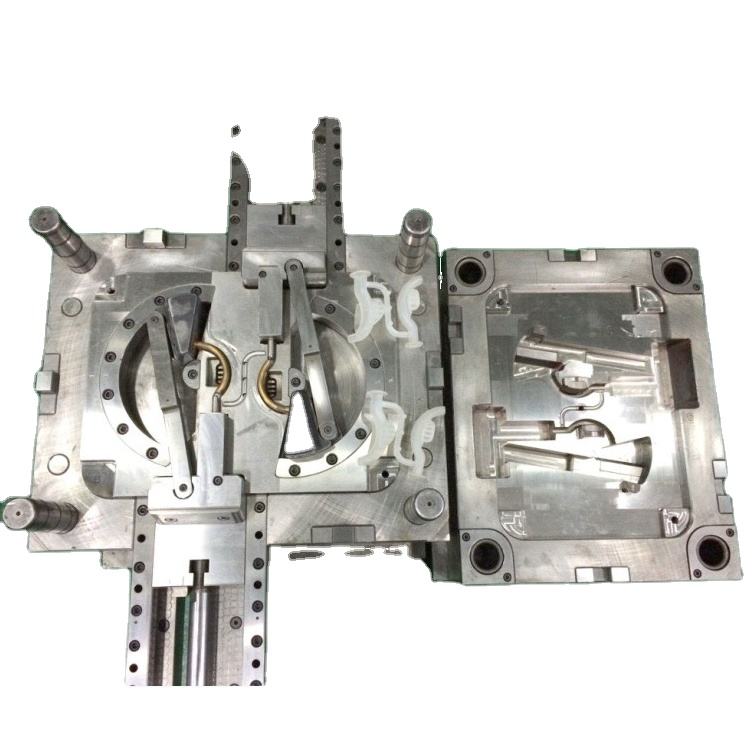

Professional Manufacturer Custom Plastic Parts,Plastic Injection Molding Service Mold making

In the realm of mould production, it is essential to have materials that not only meet the diverse needs of craftsmen, artisans, and manufacturers but exceed their expectations in performance and quality. Our cutting-edge mold-making product has been meticulously engineered with these requirements in mind, providing a solution that will revolutionize your approach to mould fabrication and patternmaking.

The key to successful mold creation lies in the material's ability to cure quickly without sacrificing the integrity of the final product. Our mold-making compound boasts an exceptionally fast curing time, allowing users to streamline their production process without the long waits associated with traditional materials. This rapid curing not only enhances productivity but also ensures that the workflow is as efficient as possible, thereby reducing downtime and increasing the turnaround for projects.

Durability is of utmost importance in mould production, and our product has been formulated to offer strong chemical resistance. This crucial feature means that the molds you create can withstand exposure to various chemicals, making them ideal for a wide range of applications. Whether you're working with resins, plastics, or more caustic materials, our mold-making solution provides the resilience needed to maintain the integrity of your molds, ensuring consistent results and prolonged usability.

One of the most notable attributes of our mold-making material is its long shelf life. We understand the importance of having a dependable product at the ready, whether you're working on a time-sensitive project or preparing for future mould fabrication endeavors. Our product's extended shelf life guarantees that you can store it for extended periods without worrying about degradation in quality or performance, providing peace of mind and reducing waste.

Designed for a wide range of mold-making applications, our product is exceptionally versatile. It is suitable for creating molds that capture intricate details, making it an indispensable asset in patternmaking. Whether you're creating molds for artistic purposes, industrial components, or consumer goods, our mold-making solution delivers the precision and detail required for high-quality mold production. This versatility also extends to its ease of use, making it accessible to both professionals and hobbyists alike.

In environments where temperature plays a critical role, our mold-making product excels with its high temperature resistance. Capable of withstanding extreme heat, it is perfect for applications that involve subsequent heating processes or exposure to high temperatures. This temperature resilience ensures that the molds you create can be used in a variety of scenarios without the risk of deformation or loss of detail, solidifying our product's role as a staple in high-performance mould fabrication.

Our mold-making product is more than just a material; it's a comprehensive solution for anyone involved in mould production. Its fast curing time, strong chemical resistance, long shelf life, high temperature resistance, and versatility in usage come together to create an unparalleled tool in the art of patternmaking and mould fabrication. Whether you're a seasoned professional or an enthusiastic amateur, our product is designed to inspire confidence in your craft and elevate the quality of your work to new heights.

Embrace the future of mold-making with our innovative product, where efficiency, durability, and precision go hand in hand. Experience the difference in your mould production projects and join the ranks of satisfied users who have discovered the outstanding benefits of our superior mold-making solution. Your quest for the perfect mold begins and ends here, with a product that promises to transform your ideas into tangible, high-quality results.

| Attribute | Details |

|---|---|

| Chemical Resistance | Strong |

| Material | Silicone |

| Temperature Resistance | High |

| Size | Various Sizes |

| Durability | High |

| Shelf Life | Long |

| Curing Time | Fast |

| Surface Finish | Smooth |

| Flexibility | Flexible |

| Precision | High |

The realm of mould fabrication is incredibly diverse, and the application occasions and scenarios for a mould making product can span across various industries. Mould manufacturing, especially with origins from China, is highly sought after due to the adherence to international standards such as the ISO certification. This ensures a level of quality and reliability that is paramount in any industry that relies on precision and durability.

When considering a mould making product with a fast curing time and a smooth surface finish, one immediately thinks of its use in high-paced industrial settings. The application of such moulds is critical in sectors that require rapid production cycles without sacrificing the quality of the end product. With the ability to supply over 100 pieces every 7 days, manufacturers are equipped to handle large scale projects, catering to a high demand for moulds in various sizes and with flexible properties.

From automotive to consumer goods, the versatility of mould design allows for a wide range of products to be created. In the automotive industry, for instance, the precision of these moulds is used to fabricate parts that must meet stringent safety and performance criteria. Similarly, in the consumer sector, everything from plastic containers to intricate toy components relies on the precision of mould design to ensure consistency and quality.

Given the minimum order quantity of 50, businesses, both large and small, can access these high-quality mould making products at a competitive price of 1, with the convenience of neutral packing. The delivery time is set at 30, enabling efficient planning and inventory management. Payment is streamlined through TT (Telegraphic Transfer), and the promise of reliability is underscored by the mould's industrial application.

Whether a business is in the early stages of product development or looking to scale up production, the flexible size options of these moulds ensure that they can be adapted to specific requirements. The fast curing time aids in reducing turnaround times, which is critical for staying competitive in the fast-paced market. A smooth surface finish is not just an aesthetic requirement but also a functional one, as it can significantly impact the performance of the final product.

In conclusion, the product attributes of origin, certification, minimum order quantity, price, packaging details, delivery time, payment terms, supply ability, application, curing time, surface finish, size, and flexibility make these mould making products from China an excellent choice for businesses looking to excel in mould fabrication, mould manufacturing, and mould design.

Place of Origin: China

Certification: ISO

Minimum Order Quantity: 50

Price: 1

Packaging Details: Neutral Packing

Delivery Time: 30 days

Payment Terms: TT

Supply Ability: 100+ pcs/week

Precision: High

Durability: High

Color: Clear

Curing Time: Fast

Flexibility: Flexible

Our Product Customization Services cater to your specific needs in Mould Production, ensuring each mould is crafted with High Precision and Durability. Our expertise in Mould Design and Mould Manufacturing allows us to deliver products that meet the highest standards of quality and efficiency. With a Fast Curing Time and Flexible properties, our molds are ideal for a wide range of applications. Choose our services for a clear advantage in mould production.

Our Mold Making Product Technical Support and Services are designed to provide you with the assistance you need to ensure your mold making process is efficient and effective. We understand the complexities involved in mold making and are dedicated to helping you achieve the best results. Our support services include but are not limited to the following:

Technical Assistance: Our team of experienced professionals is on hand to offer advice on product selection, usage, and troubleshooting. Whether you are facing issues with mold design, material selection, or processing techniques, we are here to help.

Product Guides and Documentation: We provide comprehensive guides and documentation to assist you in understanding the properties and capabilities of our mold making products. This includes detailed instructions on product use, safety data sheets, and best practices.

Training Services: We offer training sessions to help you and your team get up to speed with the latest mold making techniques and technologies. Our training can be customized to meet the specific needs of your organization and can be conducted on-site or through virtual platforms.

Quality Assurance: Our products undergo rigorous quality testing to ensure they meet the highest standards. If you encounter any quality issues with our products, our support team will work with you to resolve the problem promptly.

Product Updates: We continuously improve our mold making products and services. Stay informed about the latest product updates and enhancements that can benefit your mold making process.

Our commitment is to provide you with exceptional support and services to make your mold making endeavors successful. For further assistance, please refer to the contact us section of our website or reach out to our customer service team directly.

Product Packaging:

All our mold making products are carefully packaged to ensure they reach you in perfect condition. The product is sealed in airtight plastic bags and then placed into sturdy boxes cushioned with packing material to prevent any movement during transit. We also include a desiccant in each package to help control humidity and protect the product from any potential moisture damage.

Shipping:

We ship our mold making products worldwide using reliable courier services to guarantee timely delivery. Tracking information will be provided so that you can monitor the progress of your shipment. Please note that shipping times may vary depending on your location and customs processing. We recommend checking with your local customs office for any additional fees or regulations regarding the import of mold making products.

Q1: Where are these mold making products manufactured?

A1: Our mold making products are manufactured in China, ensuring quality and precision in production.

Q2: Do these mold making products have any certifications?

A2: Yes, our mold making products are ISO certified, adhering to high international standards.

Q3: What is the minimum order quantity for these mold making products?

A3: The minimum order quantity for our mold making products is 50 units to accommodate both small and large scale projects.

Q4: How are the mold making products packaged?

A4: Our mold making products come with neutral packing to ensure safe transportation and storage until they reach your facility.

Q5: What is the delivery time for an order of mold making products?

A5: The delivery time for our mold making products is approximately 30 days, allowing for production and logistics planning.

Q6: What are the payment terms for purchasing these mold making products?

A6: Payment terms are TT (Telegraphic Transfer), which is a secure method of payment to process your order efficiently.

Q7: What is the price per unit for these mold making products?

A7: The price per unit for our mold making products is competitively set at 1, offering value for our customers.

Q8: What is the supply ability for these mold making products?

A8: Our supply ability is over 100 pieces every 7 days, ensuring we can meet both regular and urgent demands for our products.