Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

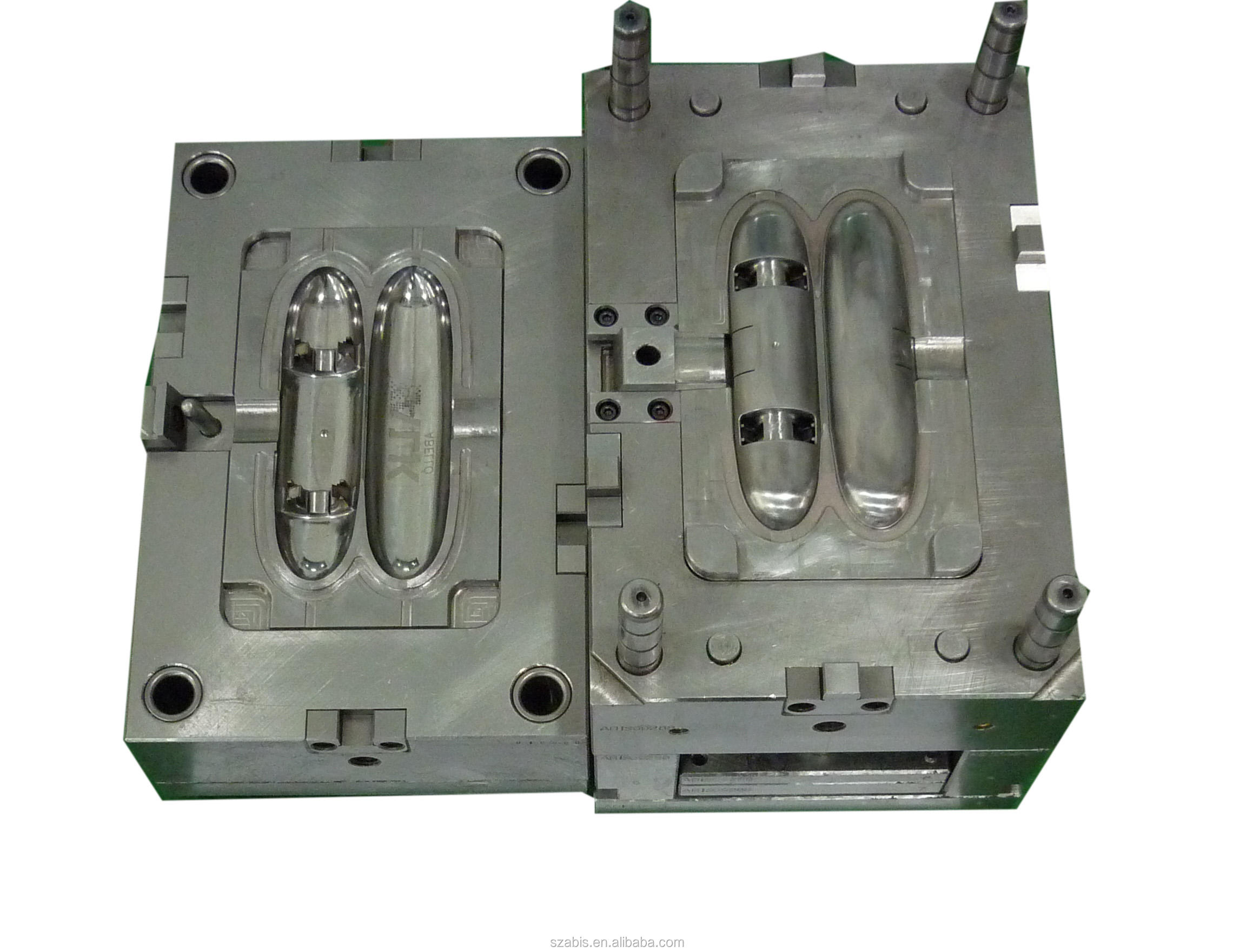

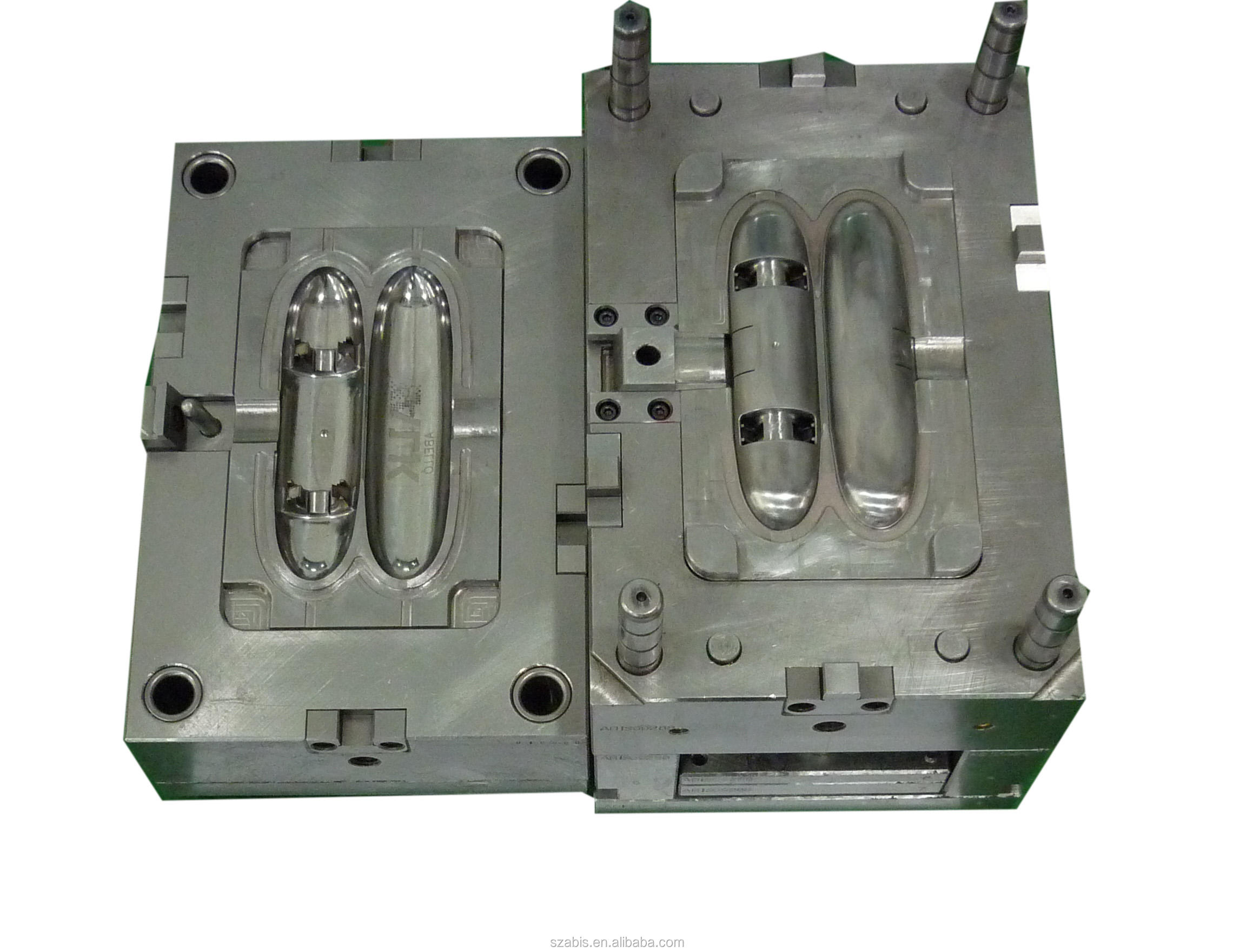

China mould maker customized colorful PP plastic shoe rack injection mold, slipper / sandal mould design

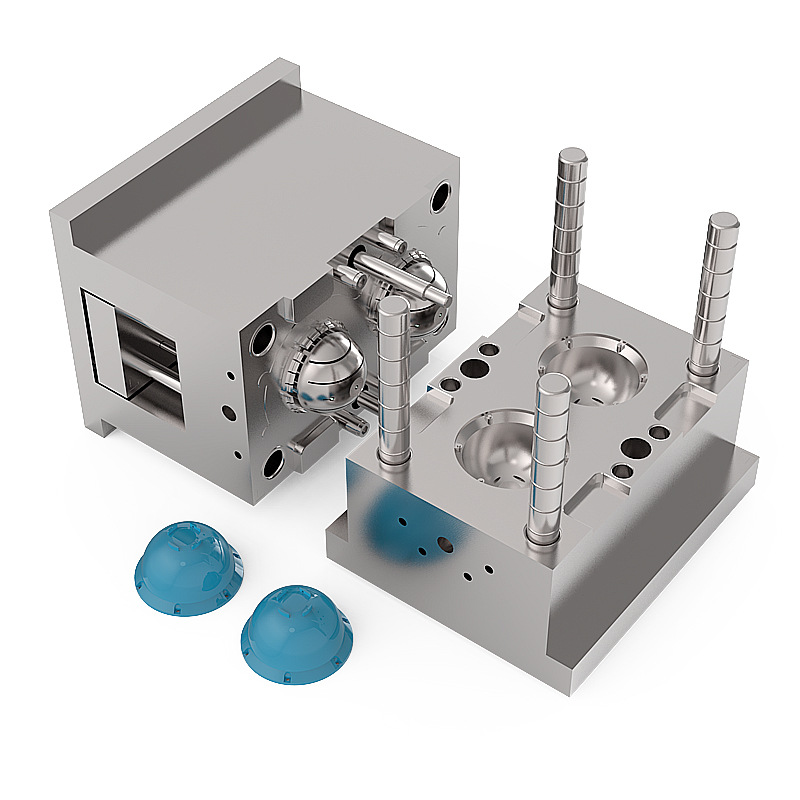

Our premium mold-making product offers unparalleled precision, flexibility, and durability, designed to meet the demanding requirements of industrial applications. When it comes to creating detailed and accurate molds, our product stands out in the market, tailored specifically for professionals engaged in patternmaking and mould fabrication. The high-precision formulation allows for the capture of intricate details, ensuring that every nuance of the original pattern is faithfully replicated in the mold. This level of accuracy is essential for industries where the slightest deviation could compromise the functionality or aesthetics of the final product.

One of the most significant attributes of our mold-making material is its flexibility. This characteristic is crucial for the demolding process, allowing for the easy release of complex shapes without causing damage to either the mold or the cast. The flexible nature of our product also contributes to its durability, as it can withstand the rigors of repeated use without cracking or tearing. This flexibility does not compromise the mold's strength or stability, ensuring that each casting is as precise as the last.

Patternmaking professionals will appreciate the long shelf life of our mold-making product. This feature ensures that the material retains its optimal properties over time, providing value and reducing waste. A long shelf life is particularly beneficial for industrial settings where materials are bought in bulk, and production schedules can be unpredictable. The assurance that the mold-making product will perform consistently, regardless of when it is used, is a testament to its superior quality and formulation.

The application of our mold-making product is primarily in the industrial sector, where high standards for quality and performance are the norms. It is ideally suited for creating molds used in large-scale manufacturing processes, where the precision and repeatability of each mold are paramount. Whether it's for automotive components, consumer goods, or intricate electronic parts, our product delivers the reliability and consistency that industrial applications demand.

Usage of the mold-making product is straightforward and user-friendly. It is designed for creating molds that can be used for various casting materials, including plastics, metals, and ceramics. The versatility of our product means that it can be adapted to a wide range of molding techniques and equipment, ensuring seamless integration into existing production workflows. Professionals in mould fabrication will find that our product not only meets but exceeds their expectations for creating high-quality molds that reflect their commitment to excellence.

In conclusion, our mold-making product is the ideal solution for industry professionals who require a high-performance material for patternmaking and mould fabrication. Its high precision, exceptional flexibility, long shelf life, and suitability for industrial applications make it a standout choice for creating molds that are both detailed and durable. When accuracy, efficiency, and quality are critical, our mold-making product delivers results that professionals can trust. Experience the ultimate in mold-making technology with our advanced product, designed to bring your most complex patterns to life with ease and precision.

| Attribute | Specification |

|---|---|

| Chemical Resistance | Strong |

| Color | Clear |

| Durability | High |

| Size | Various Sizes |

| Shelf Life | Long |

| Material | Silicone |

| Application | Industrial |

| Curing Time | Fast |

| Temperature Resistance | High |

| Precision | High |

The mold-making product, originating from China, is designed to serve a wide array of industrial applications that require the creation of patterns, molds, or replicas. These molds are essential for patternmaking, a critical step in the manufacturing process where consistent and precise replicas of parts are required. With an ISO certification, our mold-making products ensure high-quality standards that align with the stringent requirements of diverse industries.

The Minimum Order Quantity for our mold-making products is set at 50 pieces, making it an accessible option for small to medium-sized production runs. We offer these premium molds at an incredibly competitive price of just $1 per unit. Our packaging details promise neutral packing, which ensures the product's integrity and safety during transportation. With a standard delivery time of 30 days, our clients can plan their production schedules effectively without worrying about significant delays.

When it comes to payment, we accept TT (Telegraphic Transfer) for secure and reliable transactions. Our supply ability stands robust at 100+ pieces per week, demonstrating our commitment to cater to the ongoing demands of the industry. The surface finish of our molds is impeccably smooth, which is essential for producing high-quality end products that require minimal post-processing.

Applications of our mold-making products are diverse, accommodating various industrial requirements for mould production. The sizes of these molds are varied, ensuring that clients can find the perfect match for their specific needs. The strong chemical resistance of our molds ensures longevity and the ability to withstand harsh environments, which is critical for processes involving corrosive materials. Their high durability further underscores the value that these molds bring to the table, offering a prolonged service life and reducing the need for frequent replacements.

Whether it's for automotive components, consumer goods, or intricate electronic parts, our molds are the backbone of mould manufacturing. They enable businesses to maintain precision and quality throughout their production cycles. Investing in our mold-making products translates to a smooth, efficient, and cost-effective manufacturing process that stands the test of time.

Place of Origin: China

Certification: ISO

Minimum Order Quantity: 50

Price: Contact us for the latest price

Packaging Details: Neutral Packing

Delivery Time: Approximately 30 days

Payment Terms: TT (Telegraphic Transfer)

Supply Ability: 100+ pieces within 7 days

Application: Industrial

Material: Silicone

Temperature Resistance: High

Precision: High

Curing Time: Fast

Our company specializes in Mould Production , offering custom Mould Design services to meet your industrial needs. With advanced technology and expertise in Mould Production , we ensure high precision and temperature resistance for all our silicone molds, promising a fast curing time for efficiency.

Our Mold Making Product Technical Support and Services are dedicated to providing you with comprehensive assistance for all your mold-making needs. Our team of experienced technicians is well-versed in the intricacies of mold design, material selection, and process optimization to ensure that you receive the highest quality support and service.

We offer a range of services to enhance your mold-making experience, including:

Our commitment to excellence ensures that you have the support you need, when you need it, to keep your operations running smoothly and efficiently. We pride ourselves on our quick response times and our ability to provide practical solutions that address your specific challenges.

Please note that our Technical Support and Services do not include any direct contact information. For assistance, kindly refer to the contact section of our website or product manual for details on how to reach our support team.

Product Packaging: Our mold making product comes securely packaged in a durable, protective box to ensure it arrives in perfect condition. Inside, you will find the product encased in custom-fit foam padding that guards against shocks and impacts during transit. We also include a detailed instruction manual and safety guidelines to help you get started safely and efficiently.

Shipping Information: We ship our mold making product using trusted carriers to provide you with reliable and timely delivery. The standard shipping option will deliver your product within 3-5 business days, depending on your location. Expedited shipping options are available at checkout for an additional fee if you require faster delivery. Once your order is dispatched, we will provide you with a tracking number so you can monitor your package's progress. Please ensure that your shipping address is accurate to avoid any delays.

Q1: Where is the mold making product manufactured?

A1: The mold making product is manufactured in China.

Q2: Does the mold making product have any certifications?

A2: Yes, our mold making product is ISO certified, ensuring international standards of quality and safety.

Q3: What is the minimum order quantity for the mold making product?

A3: The minimum order quantity for our mold making product is 50 pieces.

Q4: Can you provide the pricing details for the mold making product?

A4: The price for the mold making product is set at 1. Please contact us for detailed pricing and bulk order discounts.

Q5: How is the product packaged and what are the delivery times?

A5: Our mold making product comes in neutral packing to ensure safe transportation. The delivery time is approximately 30 days after order confirmation.

Q6: What are the payment terms for purchasing the mold making product?

A6: The accepted payment terms for our mold making product are TT (Telegraphic Transfer).

Q7: What is the supply ability for the mold making product?

A7: We have a supply ability of over 100 pieces every 7 days.