Shenzhen Wisdomshow Technology Co.,ltd |

|

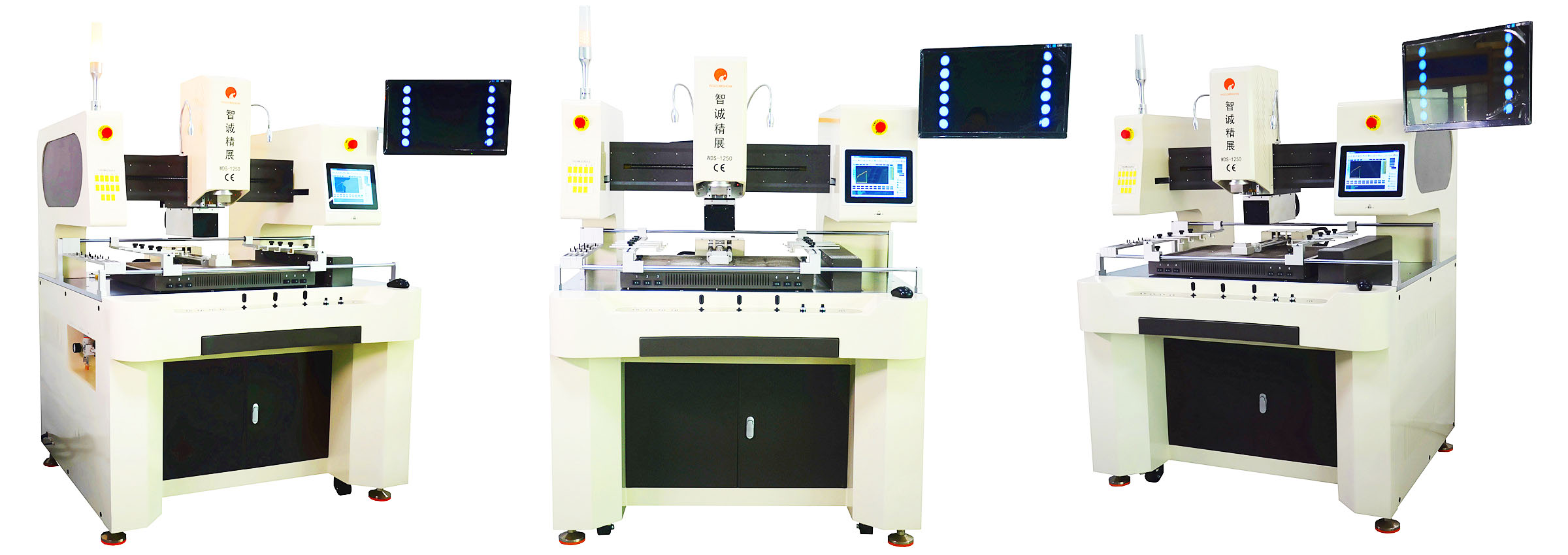

Most advanced wds-1250 full-auto bga rework station for large size pcb motherboard repair

Can't wait to know more about this machine?

Let's see some pictures first

Product Introduction:

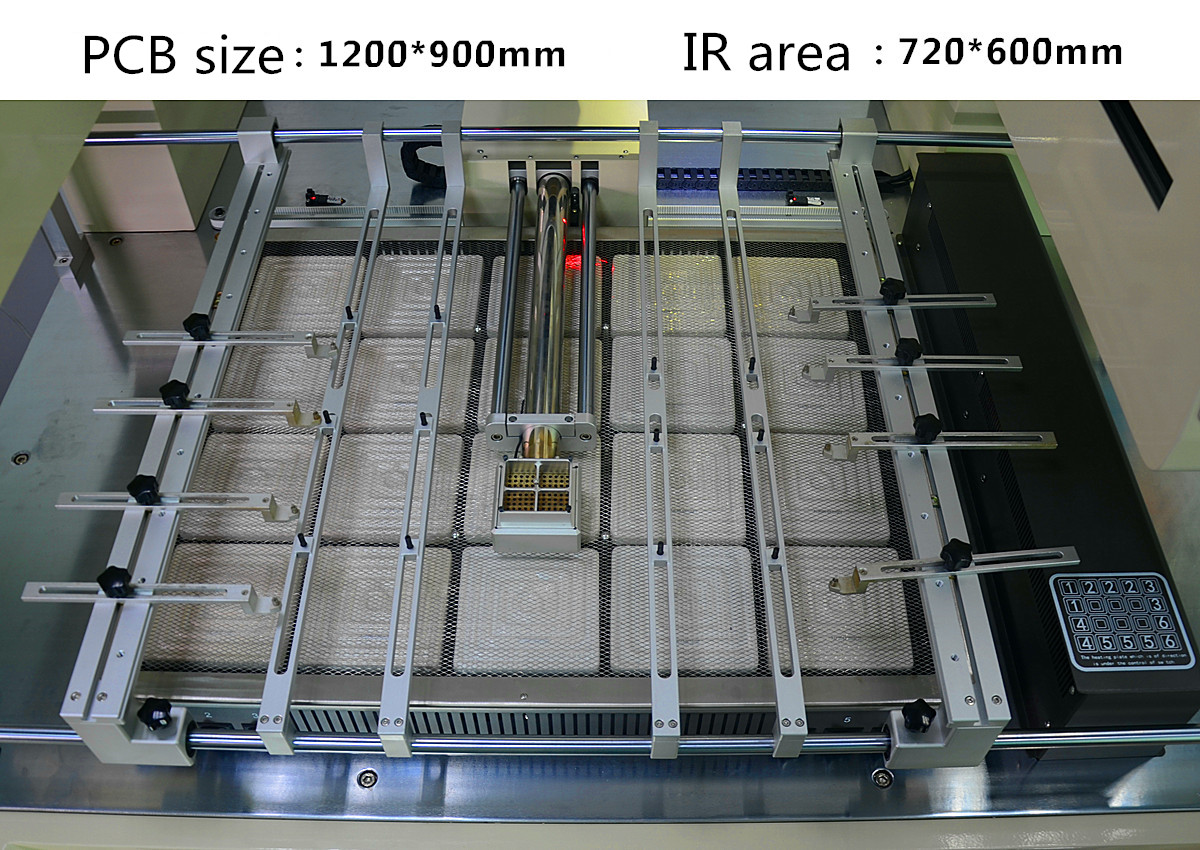

WDS-A1250 its designed for big size industrial control motherboard&5Gservice motherboardrepairing(PCB repair maximum size:1200mmX700mm),all operation is control by computer.Equipped HD optical

alignment system,hot air+IR+gas which heating way is 3 in 1(include nitrogen or compressed air).All in one BGA rework station which all movement actions are made of electric motor drive and software control.Suit for removing or soldering any kind of seal chips and BGA chips,any special or difficult chipsPOP, CCGA,

BGA,QFN,CSP,LGA,Micro SMD,MLF(Micro Lead Frames) .

Technical Parameters of WDS-1250 full-auto bga rework station

| PCB Thickness | 0.3-8mm |

| BGA Size | 0.6*0.6-120*120mm |

Min.ball pitch | 0.15mm |

Max Weight of BGA | 300g |

Placement precision | ±0.01mm |

PCB Locating Way | V shape holder&universal jigs |

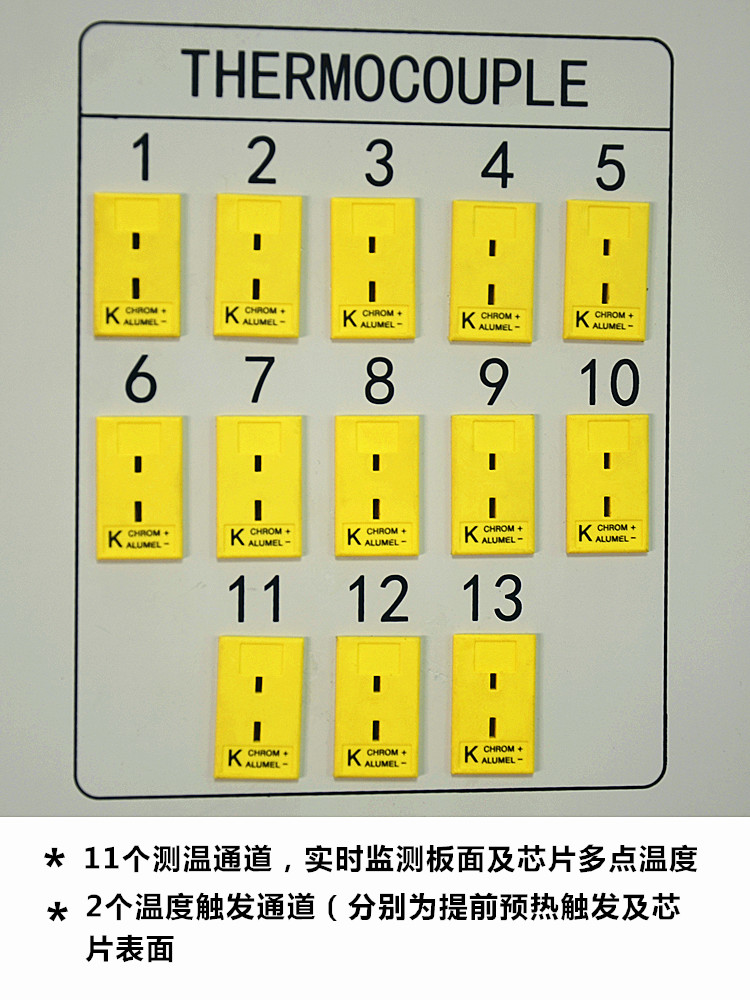

Temperature Control | High precision k shape sensor(closed loop),up&down independent temperature heating zone,precision can reach ±1℃ |

| Alignment system | Optical lens+HD industrial camera |

| Tin point monitoring | Side camera used for monitoring solder ball melting in soldering process |

Feeder system | Auto feeding system |

Specifications of WDS-1250 full-auto bga rework station

1. Your inquiry will be replied in 12 hours.

2. Original Manufacture to customers, with competitive price.

3. We provide one year warranty, free training and whole life

technology support.

4. We can arrange the shipment by air, DHL,Fedex, UPS, and by

Sea,etc for you, and will give you the tracking NO. after shipment.

5. Well-trained and Professional after-sales service team to

support you.

6. Manual and Demo video CD will package with machine, It will show

you how to use machine step by step.

7.

Payment terms ,like T/T, Westerunion, PayPal is choosed by customers.

Pre-Sales Service:

* All productiong lines have adequate quality control and QA/QC

inspectors work independently from the production line.All products

passed CE & ISO certification.

After-Sales Service:

* Offer free spare parts and service within 12 months of warranty,and

all the other relative cost should be on the buyer's account.

* Provide Demo operation video for training.If you have time,welcome

to our company,will arrange engineers to show you the operation,you

can also test the machine by yourself.

User Manual

We offer you a friendly English User manual for free.

Warranty

1 year warranty,and whole life service.

MOQ

1 set welcome, you may order more after a nice try.

Video

We can offer all kinds of videos in pre & after sale service.

How to buy

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment

methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma

invoice.

E. We prepare for your order in terms of the proforma invoice after

confirming your full payment. And 100% quality check before

shipping.

F.Send your order by airplane or by sea.

1,Standard export strong wooden package for bga rework station

2,Delivery in 2 workdays after payment confirm;

3,Shipping by TNT, UPS ,DHL,FEDEX (IE), Aramex or by air or by sea

4,Loading Port: ShenZhen or Hongkong

Click here to check more products:Shenzhen Wisdomshow Technology Co.,ltd

If you are interested in our machine,welcome to send inquiry in the below,we will reply you as soon as possible.