Shanghai Genius Industrial Co., Ltd |

|

Verified Suppliers

|

|

MIG arc welding robot introduction

The arc welding robot introduced this time is based on a robot with an imported brand (Japan OTC) with an accuracy of 0.18mm. It develops the technology of industrial robots and arc welding robots, and at the same time proves the accuracy and life of our RV reducers.

MIG arc welding robot features

MIG arc welding robot composition

Welding robots mainly include two parts: robots and welding

equipment.

The robot consists of a robot body and a control cabinet and a

teach pendant.

The welding equipment (for example, arc welding ) consists of

a welding power source, an automatic wire feeder device, and

welding torch.

6 Axis industrial robot body specification

| Robot model | ZK1400-06 | |

| Application | MIG / MAG arc welding | |

| Mounting | Vertical ground installation | |

| Number of axes | 6 | |

| Payload | 6kg | |

| Max working radius | 1400mm | |

| Repeated posiontioning accuracy | 0.03mm | |

| Maximum joint range | J1 | RV reducer ±160° |

| J2 | RV reducer +110°, -70° | |

| J3 | RV reducer +65°, -120° | |

| J4 | RV reducer ±150° | |

| J5 | Hollow harmonic reducer +105°, -110° | |

| J6 | Hollow harmonic reducer ±320° | |

| Maximum joint speed | J1 | RV reducer 201.9°/S |

| J2 | RV reducer 198.3°/S | |

| J3 | RV reducer 198.3°/S | |

| J4 | RV reducer 296.2°/S | |

| J5 | Hollow harmonic reducer 197.5°/S | |

| J6 | Hollow harmonic reducer 247.2°/S | |

| Allowable bending moment N.m | J4 | RV reducer 9.8N.m |

| J5 | RV reducer 9.8N.m | |

| J6 | Hollow harmonic reducer 4N.m | |

| Allowable inertia Kg.㎡ | J4 | RV reducer 0.3kg.㎡ |

| J5 | RV reducer 0.3kg.㎡ | |

| J6 | Hollow harmonic reducer 0.05kg.㎡ | |

| Body total weight | KG | 185KG |

| Operating environment | Temperature | 0℃ - 45℃ |

| Humidity | 20% - 80% | |

| Others | Keep away from corrosive gases or liquids or explosive gases, | |

| Power capacity | 6KVA (Robot) + 24KVA (Welding source) | |

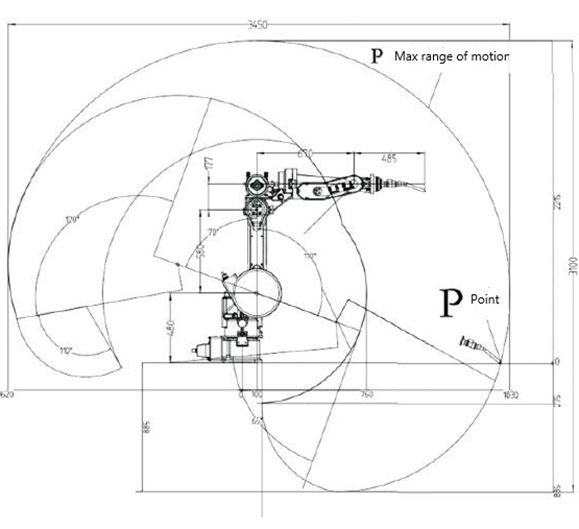

Welding robot motion range

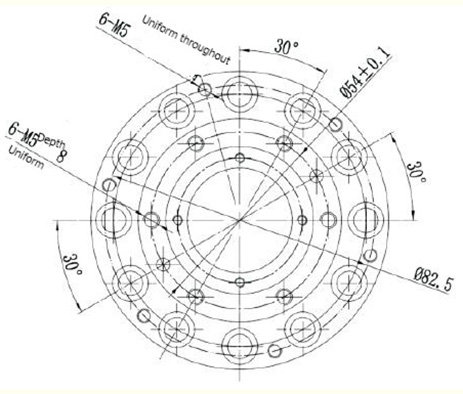

Installation dimensions of welding torch flange

Installation size of robot base

6 - Axis welding robot joint parts introduction

Welding effect

Magmeet welding power source introduction

Ehave CM500H / 500 / 350 / 250 Full Digital Heave Duty CO2 / MAG / MMA Intelligent Welder

MIG welding robot package