Changzhou Victory Technology Co., LTD |

|

Verified Suppliers

|

|

Product Description

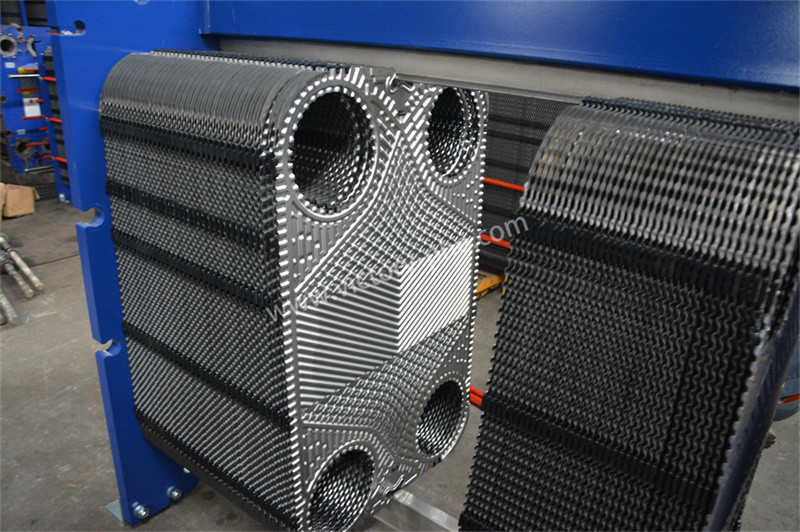

Water Oil heat Exchange Sondex Heat Exchanger Plates S100 S121 S4A Types

Sondex Heat Exchanger Plates

Heat exchanger plates are used for heat transfer in various applications due to several key advantages they offer:

Efficient Heat Transfer: Heat exchanger plates provide a large surface area for heat transfer between two fluid streams, allowing for efficient and rapid thermal exchange.

Compact Design: Plate heat exchangers offer a compact and space-efficient solution for heat transfer compared to traditional shell-and-tube heat exchangers. This is particularly advantageous in applications where space is limited.

Versatility: Heat exchanger plates can be configured in different patterns and designs to accommodate various fluid types, flow rates, and temperature differentials, making them versatile for a wide range of applications.

Energy Efficiency: By facilitating efficient heat transfer, heat exchanger plates contribute to energy savings and improved process efficiency in heating and cooling systems.

Temperature Control: Heat exchanger plates allow for precise temperature control and thermal management, making them essential in applications where maintaining specific temperature levels is critical.

Reduced Fouling and Scaling: The design of heat exchanger plates minimizes the risk of fouling and scaling, leading to improved operational efficiency and reduced maintenance requirements.

Corrosion Resistance: Heat exchanger plates are often made from materials that offer high corrosion resistance, making them suitable for use with aggressive or corrosive fluids.

Overall, the use of heat exchanger plates for heat transfer is driven by the need for efficient, reliable, and versatile solutions for heating, cooling, and thermal energy management across a wide range of industrial, commercial, and residential applications.

| Brand | Model |

Sondex | S1,S4,S4A,S7A,S8,S8A,S9A,S14,S14A,S17,S19A,S20A,S21A S22A,S31A,S22,SW26,S37,SW40A,S41,S41A,S42,S42A,S62,S43 S47,SN51,S52,S64,S65,S81,S100,S121,SF123,SF160 |

| Material | Specification |

| Stainless Steel | SUS304 316 316L 310S 904 |

| Titanium and titanium-palladium alloy | TAi TAi-Pd |

| Hastelloy | C276 D205 B2G |

| Nickel | Ni200 Ni201 |

| Molybdenum | 254 |

Heat Exchanger Plate Material Choose:

Applacations

| Plate material | Suitable for fluids |

| Stainless steel (SUS304.316, etc.) | Purified water, river water, edible oil, mineral oil |

| Titanium and titanium palladium (Ti, Ti-Pd) | Sea water, salt water, salt compounds |

| 20Cr,18Ni,6Mo(254SMO) | Dilute sulfuric acid, dilute salt aqueous solution, inorganic aqueous solution |

| Nickel (Ni) | High temperature, high concentration caustic soda |

| HASTELLOY alloy (C276, D205, B2G) | Concentrated sulfuric acid, hydrochloric acid, phosphoric acid |