Active Member

|

[China]

Address: North 5th floor, West technology park, West Wenyi Road, Zhongxin Road, Yuhang city, Zhejiang Province, China

Contact name:Hogo Lv

Hangzhou Altrasonic Technology Co., Ltd |

|

High Speed 20K Ultrasonic Spindle For Spline, Gear and Thread Elaborate Processing

Description:

Ultrasonic machining is non-traditional machining process which is used to machine brittle and hard material. This machining process comes into existence in 1950 for finishing EDM surface. Now this process is used in many industries to remove metal due to its lower cost, no heat generation, and effective machining.

Technical Parameters:

| Frequency | 20Khz/40Khz |

| Output Power | 500-1000W |

| Voltage | 110- 240V |

| Speed | 3000 - 10000 r/min |

| Power Adjusting | Step or continuous |

| Working Time Control | 24 Hours |

| Weight | 30 KG |

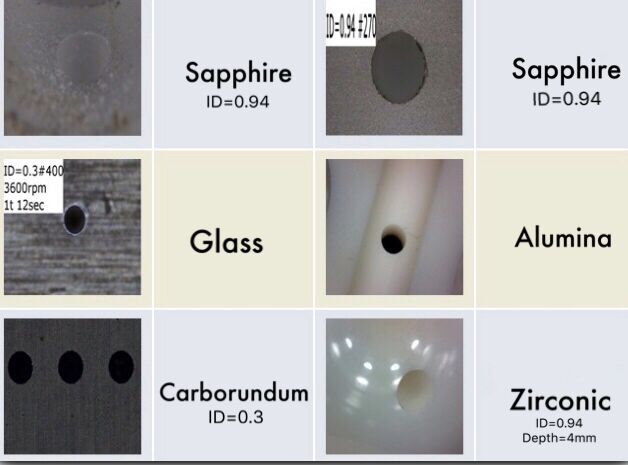

| Application | Ultrasonic Drilling/Milling/Cutting |

| Generator | Digital Generator, auto-tuning |

| Resonance point amplitude | 10um or more |

| Matching tool | mill head Φ2-Φ13; disk cutter Φ50; dilling head Φ2-Φ6 |

| Length of cable | or Customized |

Advantages:

Applications: