Active Member

|

[China]

Address: North 5th floor, West technology park, West Wenyi Road, Zhongxin Road, Yuhang city, Zhejiang Province, China

Contact name:Hogo Lv

Hangzhou Altrasonic Technology Co., Ltd |

|

20K Ultrasonic Machining Assist For High Quality Drilling or Milling In Mould industry

Description:

Ultrasonic machining, or strictly speaking the "Ultrasonic vibration machining", is a subtraction manufacturing process that removes material from the surface of a part through high frequency, low amplitude vibrations of a tool against the material surface in the presence of fine abrasive particles.

Ultrasonic machining mechanism:

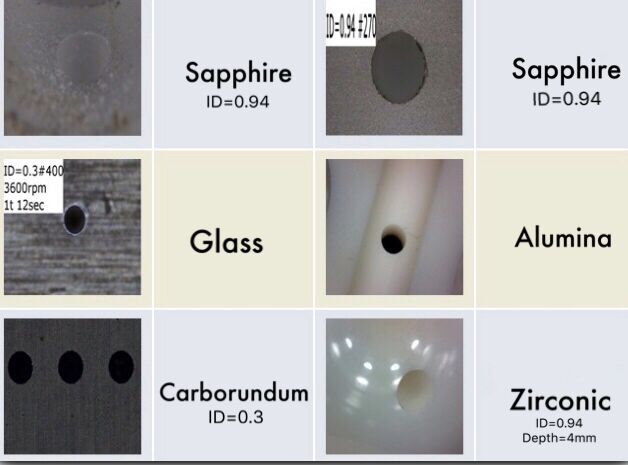

Ultrasonic machining is a molding processing method that uses the ultrasonic vibration of the tool end face to process hard and brittle materials through the abrasive suspension. Its processing materials are as follows:

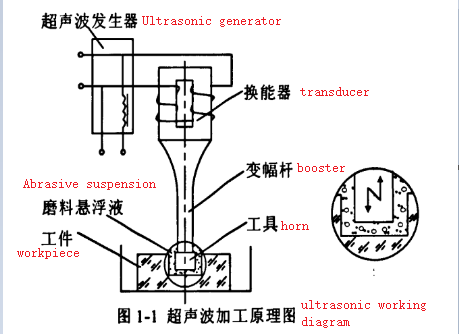

The ultrasonic generator generates a high-frequency alternating current signal of 16Khz or more, which is sent to the ultrasonic transducer, converted into ultrasonic mechanical vibration, and the amplitude is amplified by the booster, so that the tool at the lower end of the horn is strongly vibrated. Driven by the tool, the suspension containing water and abrasive also generates strong vibrations and constantly impacts the surface of the workpiece. During processing, the tool is lightly pressed against the workpiece with a small force. The surface of the workpiece is impacted by the high frequency of the abrasive at a high speed and acceleration, and is pulverized into fine particles, which are detached from the surface of the workpiece. Although the volume of particles generated by each impact is small, there are still some processing speeds due to the number of impacts per second as many as 16,000 times. The circulating flow of the suspension takes away the particles that have fallen off and the abrasive is continuously renewed. At the same time, the suspension is subjected to hydraulic shock and cavitation by ultrasonic vibration at the end of the tool, which also accelerates the mechanical damage of the workpiece surface. The tool is continuously fed, the machining process continues, and the shape edges of the tool are "copied" on the workpiece until the desired size and shape are achieved.

Technical Parameters:

| Frequency | 20Khz/40Khz |

| Output Power | 500-1000W |

| Voltage | 110- 240V |

| Speed | 3000 - 10000 r/min |

| Power Adjusting | Step or continuous |

| Working Time Control | 24 Hours |

| Weight | 30 KG |

| Application | Ultrasonic Drilling/Milling/Cutting |

| Generator | Digital Generator, auto-tuning |

| Resonance point amplitude | 10um or more |

| Matching tool | mill head Φ2-Φ13; disk cutter Φ50; dilling head Φ2-Φ6 |

| Length of cable | or Customized |

Advantages:

Applications:

It is suitable for punching, cutting, grooving, nesting, engraving, etc. of various hard and brittle materials such as glass, quartz, ceramic, silicon, ferrite, gemstone and jade. Batch deburring of small parts, surface polishing of the mold and dressing of the grinding wheel.