LIYANG APEX BIOMASS EQUIPMENT CO.,LTD |

|

Verified Suppliers

|

|

Refused Paper And Plastic Pellet Mill Machine RDF Pellet Mill

There is a waste-derived fuel that produces a higher calorific value called RPF. The full name of RPF is Refuse Paper and Plastic Fuel. It is a solid waste-derived fuel made of waste paper and waste plastics sorted from industrial waste and domestic waste as raw materials. The calorific value ranges from 20900-41800 kJ/kg. .

As we know, 90% of paper products are made from wood, and 43% of harvest wood are made into paper products. In this term, Paper recycling contributes to saving wood resources.And those wood waste is kind of high caloric value most be made pellet in power plant ,electric generated ,heating centre . So make the paper waste into paper waste pellete is a good recycling way .

And Paper waste means newspapers, magazines, cardboard and any other form of paper which is free of contaminated matter and is capable of being recycled.

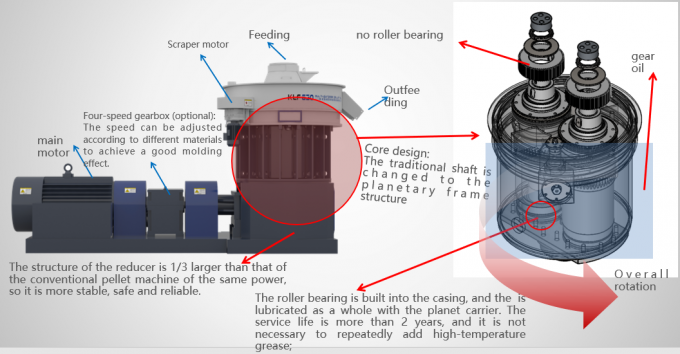

The introduction of Refused Paper And Plastic Pellet Mill Machine

The technical data :

| Model | KLF880 |

| Dimension | 4000*2000*2400 |

| Main power | 200kw |

| Ring Die size | Inner 880mm |

| Support power | 7.5kw |

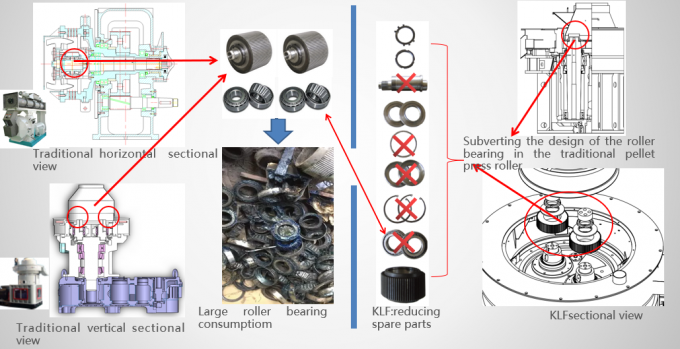

| Pelletizig chamber | no roller bearing in rollers |

| Running temperature | ≤80℃ |

| Roller adjust | Manual |

| Weight | 14ton |

| Running noise | ≤80 |

| Lubrcating method | oil free |

| Cooling method | Oil cooling |

| Output | 3-4t/h |

| Running time | 24hours |

Refused Paper And Plastic Pellet Mill Machine is suitable to make pellets with the diameters of 22mm, 24mm and 28mm, customers can use different diameters ring die to produce suitable pellets according to the actual requirements.

Application show :