LIYANG APEX BIOMASS EQUIPMENT CO.,LTD |

|

Verified Suppliers

|

|

RPF Refused Paper And Plastic Pellet Making Machine Manufacture

“RPF” is an abbreviation for Refuse derived paper and plastics densified Fuel, which is a high-grade solid recovery fuel primarily composed of waste paper and waste plastics from mostly industrial waste .This pellet calorific value ranges from 20900-41800 kJ/kg much higher than wood pellet and coal .

As we know, 90% of paper products are made from wood, and 43% of harvest wood are made into paper products. In this term, Paper recycling contributes to saving wood resources.And those wood waste is kind of high caloric value most be made pellet in power plant ,electric generated ,heating centre . So make the waste paper waste into paper waste pellete is a good recycling way .

And Paper waste means newspapers, magazines, cardboard and any other form of paper which is free of contaminated matter and is capable of being recycled.

Introduction of RPF waste pellet machine

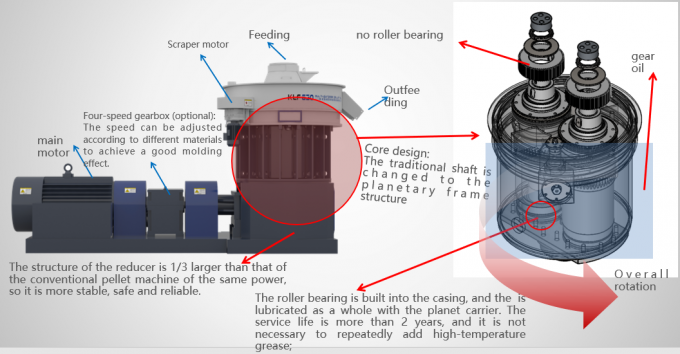

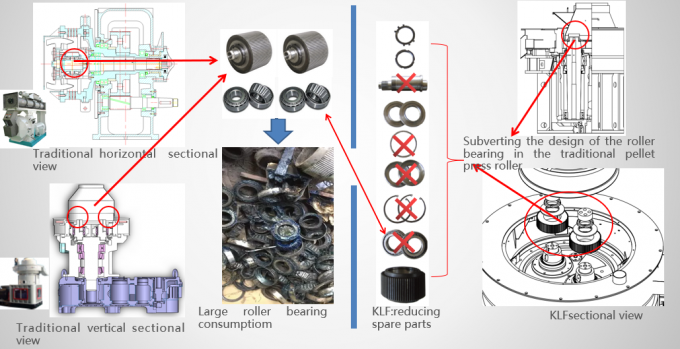

This waste Pellet mill is most eye-catching is to solve the biggest problem of the global pellet mill, burning the roller bearings and using high-cost grease. Subvert the structure and design concept of traditional pellet mill, adopt precise gear transmission, press roller without bearing, and no need for grease, energy saving and environmental protection; unique three-roller setting and high-precision planetary carrier can easily drive the material to form. The bearingless design of the pressure roller realizes continuous 24-hour non-stop work; the pressure roller is made of high-performance steel after forging, and its service life is several times that of similar products.

Quick advantage of RPF waste pellet machine

1. The pressure roller shaft has a built-in box, and no butter is required.

2. The whole oil cooling adopts a constant temperature plate cooling system, the oil temperature is constant, and the production is worry-free.

3. The double-turbo adjustment of the pressure roller is easy to operate and the adjustment is more accurate.

4. The oil temperature control system adopts automatic temperature control alarm.

5. High efficiency, energy saving, under the same power, the production capacity is increased by 30% compared with other models.

6. The double-layer design of the ring die, one ring die is dual-purpose, and the technology is environmentally friendly.

Wide range of material moisture (12%-25%)

7. The precision production of ring die and pressure roller can save 50-70% of the cost compared with other equipment. Without grease, it saves 3-5 usd in production costs compared to other equipment.

8. The equipment has low failure rate and extremely low maintenance cost.

9. Wide range of materials: waste ,sawdust, straw, bagasse,

eucalyptus bark, peanut husk, rice husk, miscellaneous wood,

bamboo, etc

The technical data :

| Model | KLF880 |

| Dimension | 4000*2000*2400 |

| Main power | 200kw |

| Ring Die size | Inner 880mm |

| Support power | 7.5kw |

| Pelletizig chamber | no roller bearing in rollers |

| Running temperature | ≤80℃ |

| Roller adjust | Manual |

| Weight | 14ton |

| Running noise | ≤80 |

| Lubrcating method | oil free |

| Cooling method | Oil cooling |

| Output | 3-4t/h |

| Running time | 24hours |

Waste Pellet mill is suitable to make pellets with the diameters of 22mm, 24mm and 28mm, customers can use different diameters ring die to produce suitable pellets according to the actual requirements.

The total process of waste pellet :

Waste Pellet application :

1. Cement kilns ·

2. RDF power plants ·

3. Coal-fired power plants ·

4. Industrial steam/heat boilers ·

5. Pellet stoves

Application show :