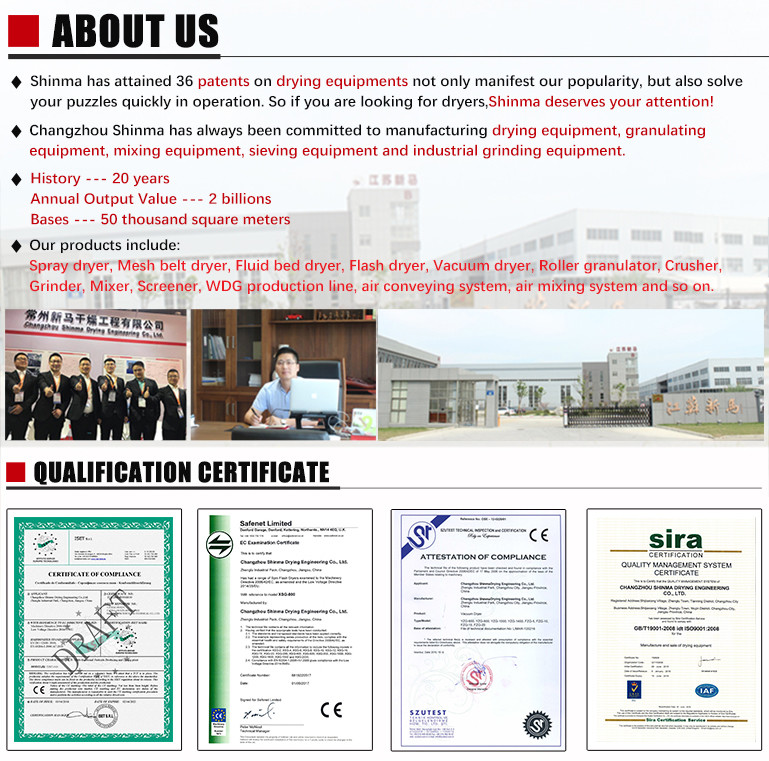

Changzhou Shinma Drying Engineering Co.,LTD. |

|

Verified Suppliers

|

|

Xsg Series Spin Flash Dryer for Cassava Flour Corn Starch Dregs

XSG Spin Flash Dryer Description

Features:

♦ Removal of surface moisture in a single-stage

♦ Short residence time and therefore low product temperature and

optimum product quality

♦ Easy to operate

♦ Fit for the purpose by using our own equipment such as fans,

cyclones, filters and screw conveyors

♦ It is possible for small equipment to carry out large-scale

production.

No | Item (XSG-10) | Data |

1 | moisture evaporation amount | 400kg/h |

2 | inner diameter(mm) | 1000 |

3 | air volume(m³/h) | 12000 |

4 | Install power(kw) | 75 |

5 | Max height(m) | 6.5 |

6 | Occupied area(㎡) | 45 |

1. Several feeding device can be chose, feeding is continuous andstable, no phenomenon of bridging.

2. There is special cooling device at the bottom of dryer, it canavoid the material that in the bottom high temperature area be bad.

3. There is special air sealing device and cooling device for bearing,it can make the life of transmission part longer effectively.

4. There is special air distributing device, it can reduce

theresistance of equipment, and make the air speed in drying

towerbecome balance.

5. There is classify ring and turbojet plate, the fineness and

finalmoisture of product can be adjusted and

controlled.6.Circumference air speed in the drying tower is high,

theresidence time of material is short, it can avoid the material

stick onthe wall and thermal sensitive materials go bad.