Guangzhou Bogeman Mechanical Seal Co., Ltd. |

|

Verified Suppliers

|

|

Burgmann Type EA560 Water Pump Seal Mechanical Seal 50mm Shaft Hole

Mechanical Seal Burgmann Seal Type EA560 Water Pump Seal Mechanical Seal

Model NO.

560A

Type

560

Balance

Unbalanced

Rotary Ring

Ceramic/Sic

Stationary Ring

Plastic Carbon/Carbon/Sic

Spring

SUS304/SUS316

Secondary Seal

NBR/EPDM/HNBR/

Trademark

Bergman

Transport Package

Carton

Specification

10mm to 50mm

Origin

China

HS Code

84842000

Replace Burgman EA560 type Metric

Operating Limits:

Pressure: | ≤1MPa |

Speed: | ≤12 m/s |

Temperature: | -30℃~+200℃ |

Rotary Ring(Plastic Carbon/Carbon/Sic/tc)

Stationary Ring(Ceramic/Sic/Tc)

Secondary Seal(nbr/Epdm/)

Spring & Other Parts(Sus304/Sus316)

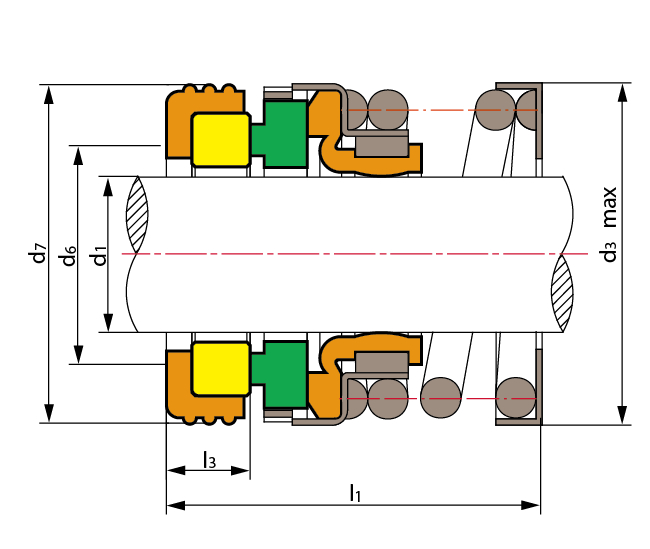

Structural model

EA560 parameter table on the left 560B inch parameter table on the right

Model | d1(mm) | d3 | d6 | d7 | l1 | l3 |

BGM 560A-10 | 10 | 23.5 | 16 | 24 | 25 | 7 |

BGM 560A-11 | 11 | 23.5 | 16 | 24 | 25 | 7 |

BGM 560A-12 | 12 | 26 | 17 | 26 | 25 | 7 |

BGM 560A-14 | 14 | 28 | 21 | 28 | 25.5 | 7 |

BGM 560A-15 | 15 | 30 | 21 | 28 | 29.5 | 7 |

BGM 560A-16 | 16 | 32 | 22 | 28/32 | 33.5 | 10 |

BGM 560A-18 | 18 | 32.5 | 25 | 35 | 36.5 | 10 |

BGM 560A-19 | 19 | 32.5 | 25 | 35 | 36.5 | 10 |

BGM 560A-20 | 20 | 35.5 | 27 | 38 | 38 | 10 |

BGM 560A-22 | 22 | 37.5 | 29 | 38/40 | 40.3 | 10 |

BGM 560A-25 | 25 | 42 | 32 | 44 | 39.3 | 10 |

BGM 560A-28 | 28 | 47 | 34 | 46 | 40 | 10.0 |

BGM 560A-30S | 30 | 46 | 35 | 45 | 38.2 | 7.5 |

BGM 560A-30L | 30 | 48 | 38 | 50 | 40 | 10.0 |

BGM 560A-32 | 32 | 50 | 40 | 54 | 40 | 10 |

BGM 560A-35 | 35 | 54.5 | 44 | 58 | 42 | 10 |

BGM 560A-38 | 38 | 58.5 | 46 | 60 | 42.6 | 10 |

BGM 560A-40 | 40 | 62.5 | 48 | 64 | 42.6 | 10 |

BGM 560A-45 | 45 | 66.5 | 52 | 66 | 45 | 10 |

BGM 560A-50 | 50 | 72.5 | 58 | 72 | 54.6 | 11.5 |

BGM 560A-55S | 55 | 72 | 60 | 75 | 59.4 | 12 |

BGM 560A-55L | 55 | 76 | 60 | 78 | 59.8 | 12 |

BGM 560A-60 | 60 | 80 | 65 | 80 | 63 | 12 |

BGM 560A-65 | 65 | 85 | 70 | 85 | 64 | 13 |

BGM 560A-70 | 70 | 92 | 75 | 92 | 60 | 11 |

Product real shot, excellent workmanship, durable, bulk spot

We are a manufacturer. All seals have bulk inventory and can be shipped to you quickly. We promise to ship you in small quantities within 3 days.Advanced technology, excellence, replace original

1. Different models of mechanicals seals for a wide variety of

Grundfos® pumps, among them: CR(N), NB, NK, CLM, LP, TP, etc.

Available in diverse combinations of materials and different

diameters: 12, 16, 22, 28, 33, etc. Also mechanical seals for

Sarlin®. Division of waster pumps. Available in various materials:

silicon-graphite carbide, silicon carbide-silicon carbide; combined

with EPDM and FKM elastomers.

2. Mechanical seals are available for different references

Gorman-Rupp® pumps. Special models for the transfer of clean water,

sewage, oil industry, agriculture and others.

GRN-38'1

3. Mechanical seals for Fristam® pumps. Wide range of models and

materials in the most standard diameters: 22,30 and 35 mm.

Different assembly possibilities for the most well-known pump

models: FP, FL and FT.

4. Broad range of mechanical seals compatible with Flygt® and

Grindex® waste water pumps. These mechanical seals are

characterized by their easy and fast installation, without having

to make any modification to the pump. Manufactured in stainless

steel and in solid tungsten carbide. Special tools are not

necessary for their installation.

5. Mechanical seals for EMU® pumps. They get two static faces and

one rotating face. We can supply the complete seal or spare faces.

6. Different designs of mechanical seals for Ebara® pumps, single

and double seals in combinations carbide-silicon carbide and

graphite-aluminium oxide.

7. Mechanical seals for all types of Calpeda® pumps: centrifugal

pumps, multistage, submersible. Different models of mechanical

seals in a wide range of materials.

8. Mechanical seals compatible for APV® pumps, among them: Puma,

ZMA, ZMB, ZMD, ZMS, ZMH, ZMK. Rosista® and Pasilac®, W and W+. Some

designs with wave spring like the special seals for APV Howard®

pumps and Crepaco Clean Line®. All of them have been manufactured

in materials suitable for working with fluids such as juices, milk

and drinks in general.

9. Allweiler, Simple design of mechanical seals simple but with

special measures for this type of pump.

10. Different models of mechanical seals compatible for Alfa-Laval®

pumps series CM, FM, MR, LKH,GM and ALC. Also the models for the

range of lobular SSP and SR pumps. Mechanical seals in different

combination of materials tungsten carbide, silicon carbide,

graphite; combined with different types of elastomers: NBR, EPDM

and FKM.

11. Mechanical seals for ABS® submergible pumps specific wastewater

treatment. Different models of mechanical seal available: oil

chamber mechanical seal and water mechanical seal.

Factory real shot, production site, finished product inventory, bulk spot

Fixing and Applying Directions of Mechanical Seals

1. The radial acting deviation for the shaft(shaft sleeve) of the installed mechanical seal shall be 0.04mm by maximum while the axial movement value of the rotor shall be no more than 0.1mm. |

2. The seal cover (or shaft cover) of the stationary ring of the installed mechanical seals,the vertical degree of the seal face should be 0.04mm by maximum. |

3. When installing the mechanical seals,the shaft(shaft

sleeve),seal chamber,seal face as well as the mechanical seal face |

4. When conveying medium of over high or low temperature,with medium which are easy catch fire,easy for explosion.Related mechanical seal standards must be referred to take appropriate measures such as quench,rinsing,coolong and filtrating. |

5. Appropricate lubrication must be choosen when mechanical seal is installed.The installment size of the mechanical seal must be guaranteed to the installment instruction. |

6. Before the machine starts running,the hermetic compartment shall be full of medium and well lubricated.Dry friction which may lead to the damage of the air-tightness is strict forbidden. |