Active Member

|

Address: Block A1, Xingfu Lantian technology zone,Tangxia Yong, SongGang Town, Bao'an district, Shenzhen, China

Contact name:Sharon Hu

NTT Mould Co., Ltd. |

|

ABS Plastic Parts Injection Mould Tool 1 Cavity Mold Cold Runner Wedge

1. Product introduction

| Mold No. | NTT-607-16 |

| Part Name | 2AE-00281_IST-2_TSG_WEDGE |

| Material | NAK80 |

| No. of Cavities | 1 |

| Injection System | Cold Runner/ Edge gate |

| Shrinkage | 1.005 |

| Resin | PC/ABS |

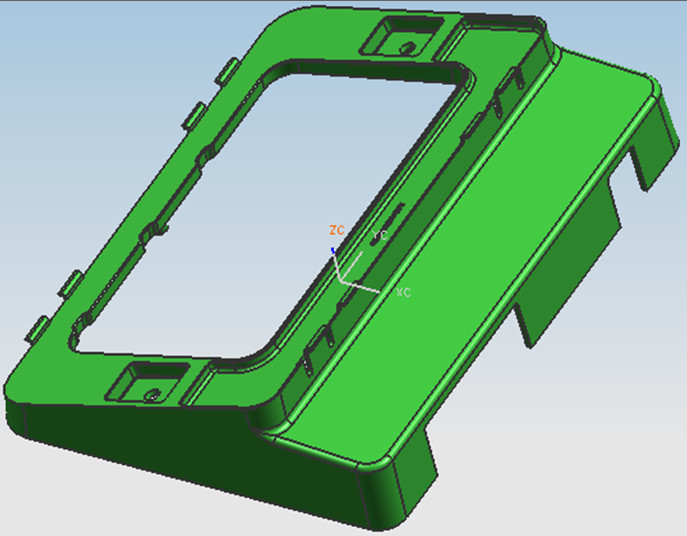

Part 3D Drawing

NTT Mould specializes in manufacturing a variety of plastic injection molds, molded parts and assembly.

Over 90% of molds and parts export to North America as well as Europe, such as United Staes, Canada, Germany, Australia, and many more.

If possible, we would like to invite anyone who may interest to pay a visit to our facility, so that you might be better to understand our capabilities to be of assistance to your company.

Please keep in mind NTT Mould if there is any new projects coming up, thanks.

Our capabilities and rich experience enable us to undertake projects from concept to completion.

2. Why customers choose NTT Mould?

1. Design experience for many years

2. The strength of production capacity, can supply 300--400

sets per year and delivery on time

3. Good quality

4. Good cuminication skills and good service with customers,

schedule are made

Weekly reports with detaild photos, sent to customers for

monitoring

5. We are not only supply plastic mould, also supply rapid

prototypes

6. Provide low-volume production for ensure mould quality

before shipment

3. Plastic Mold Expertise:

1. Injection moulds for automotive(Auto Bumper mould, Auto

Door mould, Auto Lamp mould...)

2. Plastic moulds for Home Appliances(washing machine mould,

TV mould, air conditioner mould)

3. Plastic injection mold for electronic products

4. Plastic molding for household products(bucket mould.

Basket mould, trash bin mould, chair mould...)

4. Documents for Mold Shipment

1. Tool check-list.

2. Steel certifications.

3. Steel dimensions report.

4. Mold tryout process sheet.

5. Tool assembly drawing printings.

6. Part drawing and latest dimensions report.

7. CD contains 2D & 3D mold drawing, electrode data and

all above information.

5. Advantage:

| 1. Huge capacity |

| 2. Ensure quick response to any problem. |

| 3. Our equipments to serve the whole process from machining to inspection to mold trials,can provide mould progess photos every week. |

| 4. We can provide steel certification,and heat treatment certification |

6. Project Process

● RFQ

● Quotation

● PO

● DFM

● Mold Design

● Design Approved

● Steel Ordering

● Machining

● Mold Trial

● Sample Approved

● Texture

● Delivery

1. Before mold build, a rough layout of the mold design (DFM) can be sent as a PPT format.

2. After you approve the DFM, we would give you a full detailed mold design in 2D and 3D drawing.

3. Once the mold design approved, we will start to build the mold strictly according to your requests.

Every week, we will send you weekly report with components (electrode, cavity, core, mold base) picture to show you the process of the project.

4. When we make T1 samples, we will make a video to you, and also send samples with molding report for your approval.

5. Only everything of the mold and sample is confirmed OK from your side, we will arrange the mold shipment and send you mold inspection report as well.

We take carefully with every step to make sure our quality, and what we can do, we surely try our best to work on it.

If you have any new mould project, please sent your 2D/3D drawing or sample picture with whole of dimentions to us, we will reply your soon.