Active Member

|

Address: Block A1, Xingfu Lantian technology zone,Tangxia Yong, SongGang Town, Bao'an district, Shenzhen, China

Contact name:Sharon Hu

NTT Mould Co., Ltd. |

|

OEM PC ABS Injection Molding Tool Green Parts Cerified ISO9001 2008

Project Details

| Project Number: | NTT-601-40 |

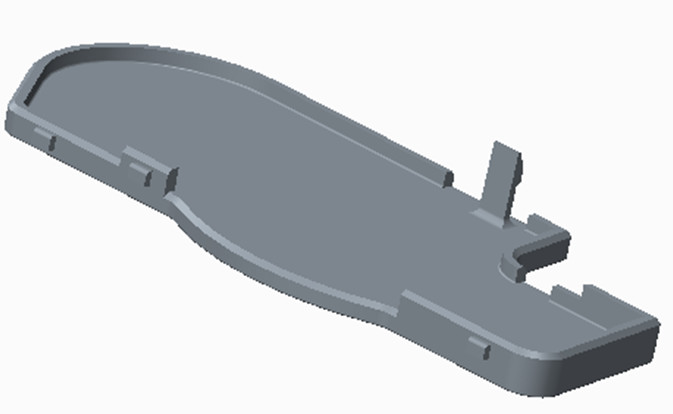

| Part Name: | Cover service |

| Drwaing Number: | DM-01002520 |

| Injection System: | Cold runner, sub gate |

| Numbers of Cavity: | 1 cavity |

| Resin: | ABS+PC |

| Shrinkage: | 0.5% |

| Core/ Cavity Steel: | 1.2738 |

| Part Color: | Green |

Drawing Picture

Order Process:

1. Send us the drawing with specifications for the quality, mould

life and others requirments.

2. Get a quote from us with Moluld costs and basis information and

part prices.

3. Negotiation of the quality, price, material, delivery time,

payment term and others

4. Confirm and Place an order with first downpayment.

5. We will analyse with your products and provide a DFM to you for

making sure is good to make mold and producing.

6. Send mold design for customer approval before making mold

7. Order materials and begin to machining, update the manufacturing

information once a week.

8. Assemble the mold and Try out for the First samples.

9. self- inspecting and send the samples with our inspection report

to customer for confirmation

7. If the first sample comes out and satisfied, the mold finished.

If not satisfied, we will modify until meeting customer's

requirements.

8. Delivery of goods by sea or by air according customer's

requirement

If you have any new inquiry, you can go ahead to send for quoting, we are pleased to show our price to you.