CHENGDU CHUANGRONG TRADING CO.,LTD |

|

Electrofusion HDPE Fittings End Cap for Water and Gas supply PN16 SDR11 PE100

Production Description of Electrofusion HDPE End Cap

-Electrofusion HDPE fittings are welded by electrofusion machine to connect HDPE pipes together:

After electrofusion welding machine plug in electricity and turn on, The copper wire buried inserted in

electric fuse HDPE fittings are heated and make HDPE melt, Which joint HDPE pipe and fittings well.

Adavantages of CHUANGRONG Electrofusion HDPE Fittings

1.Professional Solution

1) Accept customer OEM production, large quantity customization requirements.

2) Technical support:Professional engineers and senior, special engineers provide technical support:

More than 80 Technique personnel,20 Middle class engineer,8 Senior Engineers.

3)More than 100 sets injection molding machine and the largest (300,000g)domestic injection molding

machine;Over 20 units of automation robot, 8 sets automation Electrofusion fittings production system.

4)Various type(Elbow,Coupler,Tee,End Cap,Saddle,Ball Valve etc) and completed specification(Ranged

from 20-630 Electrofusion type)

5)Annual production capacity up to 13000 tons(More than 10 million pieces or more)

2.Technical Support

The key factors of product quality are technical support and material selection

Installed successfully. Our strong and efficient teamwork provides customers with the best solution in a

timely manner: the sales team understands and understands the customer's use and proposes suitable

HDPE pipeline solutions and products. The production department coordinates the production plan to

ensure the fastest delivery time. Engineers and technicians solve and provide technical product perform

ance and technical support.

3.Customized services

The team of CHUANGRONG pipeline system provides corresponding solutions according to customer

needs:Various special solutions can be produced in small batches.

Standardized processes ensure highest quality

Personalized solutions for customers.

4.Thoughtful Service

CHUANGRONG, as China's "GF", we fully understand the needs of customers and provide customers

with the most cost-effective solutions --- one-stop product portfolio of HDPE pipe systems (HDPE pipes,

fittings, welding machines and tools. Also for customers Provide high value-added services, 24 hours to

answer customer questions.

5. Environmental

CHUANGRONG HDPE pipeline system integrates its environmental responsibility into its daily business

activities.HDPE is a green environmental protection material, which can be recycled without causing pollution

to the environment.

We work hard to conserve natural resources and constantly strive to optimize the environmental performance

of our products and how they

used.

Production Workshop of Electrofusion HDPE Fittings

P2:4.7 Pin(4.0 welded by Switched adaptor) P3:Printed Parameters P4:Embedded copper wire

1)Fusion Pin of Electrofusion HDPE fittings

4.7mm Pin of Electrofusion HDPE fittings produced.

Besides switched adaptors for 4.0 Pin supplied to suit claw of 4.0 electrofusion machine.

2)Moulded-in welding parameters

Welding parameters as per EN1555 is printed on the fittings, Such as Products' name,OD(mm),PE100,

PN16 SDR11.

Bar code is also attached on the electrofusion fittings for scanning.

3)Element&Stops

To promote joint quality,all elements are coated with polyethylene before being moulded into the fitting body.

All fittings have removable pipe stops.The stops ensure pipes cannot be inserted past the midpoint,but can

be removed for use in,for example,repair situations.

4)High quality copper wire embed in the HDPE fittings which have Good thermal conductivity.

Details of Electrofusion HDPE End Cap

Products name | Electrofusion HDPE End Cap |

Sizes Available | As below specification sheet in detail |

SDR | SDR11,SDR17 |

PN | PN16,PN10 |

Material Brand | SINOPEC, BASELL, SABIC, BOROUGE etc |

Executive Standard | EN 12201-3:2011,EN 1555-3:2010 |

Colors Available | Black color , blue color, Orange or as request. |

Packing Method | Normal export packing. by carton |

Production Lead Time | Depending on the order quantity. |

Certificate | ISO, CE,BV,Factory Test Report |

Supply Ability | 100000 Ton/Year |

Payment Method | T/T, L/C at sight |

Trading Method | EXW, FOB, CFR, CIF,DDU |

Specification of Electrofusion HDPE End Cap

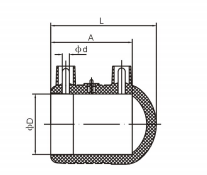

Specification φD | L | A | φd |

| 32 | 60 | 45 | 4.7 |

| 40 | 70 | 55 | 4.7 |

| 50 | 70 | 55 | 4.7 |

| 63 | 80 | 55 | 4.7 |

| 90 | 95 | 55 | 4.7 |

| 110 | 105 | 70 | 4.7 |

Applications of Electrofusion HDPE Fittings

1.Municipal water supply, gas supply and agriculture etc.

2.Commercial & Residential water supply

3.Industrial liquids transportation

4.Sewage treatment

5. Food and chemical industry

7. Replacement of cement pipes and steel pipes

8. Argillaceous silt, mud transportation

9. Garden green pipe networks

Inspection Equipment

Finished products get well inspection before delivery.

Factory Test report

| Test item | Standard | Conditions | Results | Unit |

| 1.Melt Flow Index | ISO1133 | 190°C & 5.0Kg 0.2-0.7 | 0.49 | g/10min |

| 2.Density | ISO1183 | @23°C ≥0.95 | 0.960 | g/cm3 |

| 3.Oxidation Induction Time | ISO11357 | 210°C >20 | 39 | Min |

| 4. Hydrostatic Pressure Test | ISO1167 | 80°C 165h, 5.4Mpa | Passed | |

| 5 Size Check | ISO3126 | 23°C | Passed | |

| 6 Appearance | Clean& Smooth | 23°C | Passed |

Certifications

We can supply ISO9001-2008, BV ,SGS, CE etc certification.

All kinds of products are regularly conducted pressure-tight

blasting test,longitudinal shrinkage rate test,

quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products

totally reach the relevant standards from raw materials to finished products.