Hebei Jingxian Huamei Mining Machinery Manufacturing Co., Ltd. |

|

Verified Suppliers

|

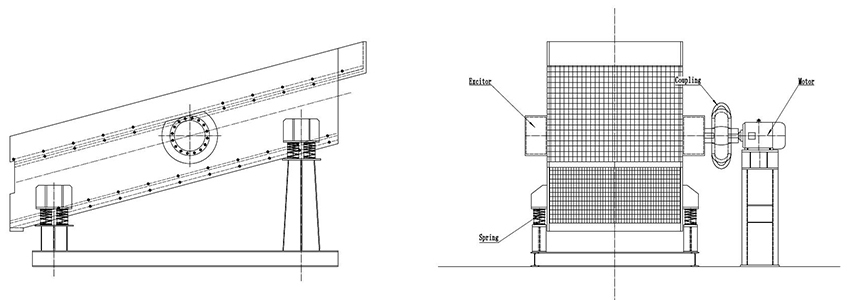

Circular Vibrating Screen

How it works

Circular vibrating screen’s shaft line is at the center of gravity,

resulting in a circular motion on all points of the screen.

Particles are moved forward by the screen motion and gravity effect

causing from screen angle. The material’s travel speed is even all

along the decks.

The shaft line is made of modular vibrators with flange mounted on

the side walls and synchronized by cardan shaft.

The eccentric counterweights of each modular vibrator creating the

wanted stroke. We offer vibrators’ exchange program for facilitate

the servicing.

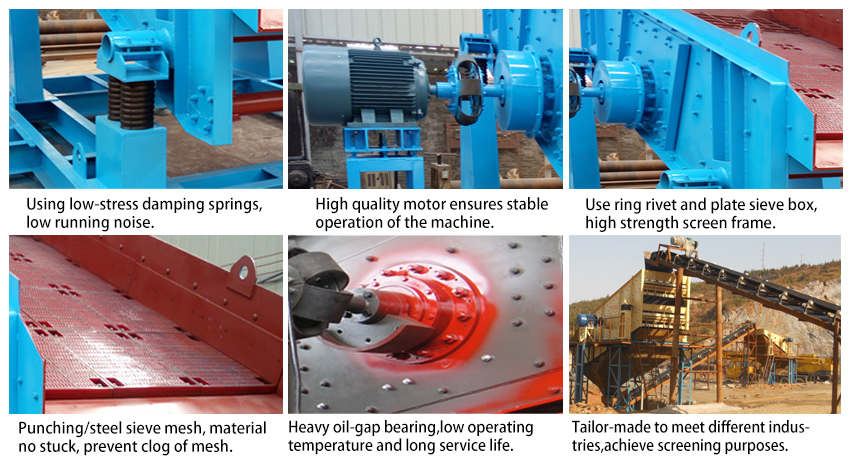

FEATURES

| Circular Vibrating Screen Technical Specifications | ||||||||||

| Model | Layers | Area (㎡) | Angle (°) | Mesh size (mm) | Max feed size (mm) | Capacity (t/h) | Frequency (rpm) | Power (kw) | Overall Dimension (mm) | |

| YA1236 | 1 | 4.3 | 20 | 6~50 | ≤200 | 75~245 | 845 | 11 | 3757*2364*2456 | |

| 2YA1236 | 2 | 4.3 | 20 | 6~50 | ≤200 | 75~245 | 845 | 11 | 3757*2364*2456 | |

| YA1530 | 1 | 4.5 | 20 | 6~50 | ≤200 | 80~255 | 845 | 11 | 3184*2670*2280 | |

| YA1536 | 1 | 5.4 | 20 | 6~50 | ≤200 | 95~310 | 845 | 11 | 3757*2670*2419 | |

| 2YA1536 | 2 | 5.4 | 20 | 6~50 | ≤200 | 95~310 | 845 | 15 | 3757*2715*2419 | |

| YAH1536 | 1 | 5.4 | 20 | 6~50 | ≤400 | 240~660 | 755 | 11 | 3757*2670*2437 | |

| 2YAH1536 | 2 | 5.4 | 20 | 6~150 | ≤400 | 240~660 | 755 | 15 | 3757*2715*2437 | |

| YA1542 | 1 | 6.3 | 20 | 6~50 | ≤200 | 110~360 | 845 | 11 | 4331*2670*2655 | |

| 2YA1542 | 2 | 6.3 | 20 | 6~50 | ≤200 | 110~360 | 845 | 15 | 4331*2715*2675 | |

| YA1548 | 1 | 7.2 | 20 | 6~50 | ≤200 | 125~410 | 845 | 15 | 4904*2715*2854 | |

| 2YA1548 | 2 | 7.2 | 20 | 6~50 | ≤200 | 125~410 | 845 | 15 | 4904*2715*2861 | |

| YAH1548 | 1 | 7.2 | 20 | 6~150 | ≤400 | 320~780 | 755 | 15 | 4904*2715*2943 | |

| 2YAH1548 | 2 | 7.2 | 20 | 30~150 | ≤400 | 320~780 | 755 | 15 | 4904*2715*2943 | |

| YA1836 | 1 | 6.5 | 20 | 6~50 | ≤200 | 115~370 | 845 | 11 | 3757*2975*2419 | |

| 2YA1836 | 2 | 6.5 | 20 | 6~50 | ≤200 | 115~370 | 845 | 15 | 3757*2975*2419 | |

| YAH1836 | 1 | 6.5 | 20 | 6~50 | ≤400 | 290~800 | 755 | 11 | 3757*2975*2437 | |

| 2YAH1836 | 2 | 6.5 | 20 | 30~150 | ≤400 | 290~800 | 755 | 15 | 3757*3020*2437 | |

| YA1842 | 1 | 7.6 | 20 | 6~50 | ≤200 | 135~430 | 845 | 15 | 4331*3020*2675 | |

| 2YA1842 | 2 | 7.6 | 20 | 6~50 | ≤200 | 135~430 | 845 | 15 | 4331*3020*2675 | |

| YAH1842 | 1 | 7.6 | 20 | 6~50 | ≤400 | 340~900 | 755 | 15 | 4331*3020*2700 | |

| 2YAH1842 | 2 | 7.6 | 20 | 6~150 | ≤400 | 340~900 | 755 | 15 | 4331*3020*2700 | |

| YA1848 | 1 | 8.6 | 20 | 6~50 | ≤200 | 150~490 | 845 | 15 | 4904*3020*2861 | |

| 2YA1848 | 2 | 8.6 | 20 | 6~50 | ≤200 | 150~490 | 845 | 15 | 4904*3020*2861 | |

| YAH1848 | 1 | 8.6 | 20 | 30~150 | ≤200 | 385~1000 | 755 | 15 | 4904*3020*2943 | |

| 2YAH1848 | 2 | 8.6 | 20 | 6~150 | ≤400 | 385~1000 | 755 | 15 | 4904*3020*2943 | |

| YA2148 | 1 | 10 | 20 | 6~50 | ≤200 | 175~570 | 748 | 18.5 | 4945*3423*3515 | |

| 2YA2148 | 2 | 10 | 20 | 6~50 | ≤200 | 175~570 | 748 | 22 | 4945*3463*3515 | |

| YAH2148 | 1 | 10 | 20 | 30~150 | ≤400 | 445~1200 | 708 | 18.5 | 4945*3423*3501 | |

| 2YAH2148 | 2 | 10 | 20 | 6~150 | ≤400 | 445~1200 | 708 | 22 | 6092*3463*3501 | |

| YA2160 | 1 | 12.6 | 20 | 6~50 | ≤200 | 220~715 | 748 | 18.5 | 6092*3423*3674 | |

| 2YA2160 | 2 | 12.6 | 20 | 6~50 | ≤200 | 220~715 | 748 | 22 | 6092*3463*3674 | |

| YAH2160 | 1 | 12.6 | 20 | 30~150 | ≤400 | 565~1400 | 708 | 30 | 6116*3619*3849 | |

| 2YAH2160 | 2 | 12.6 | 20 | 6~150 | ≤400 | 565~1400 | 708 | 30 | 6116*3619*3849 | |

| YA2448 | 1 | 11.5 | 20 | 6~50 | ≤200 | 200~650 | 748 | 18.5 | 4945*3728*3473 | |

| YAH2448 | 1 | 11.5 | 20 | 30~150 | ≤400 | 515~1300 | 708 | 30 | 4970*3925*3638 | |

| 2YAH2448 | 2 | 11.5 | 20 | 30~150 | ≤400 | 515~1300 | 708 | 30 | 4970*3925*3638 | |

| YA2460 | 1 | 14.4 | 20 | 6~50 | ≤200 | 250~810 | 748 | 30 | 6091*3925*3850 | |

| 2YA2460 | 2 | 14.4 | 20 | 6~50 | ≤200 | 250~810 | 748 | 30 | 6091*3925*3850 | |

| YAH2460 | 1 | 14.4 | 20 | 30~150 | ≤400 | 645~1500 | 708 | 30 | 6091*3925*3846 | |

| 2YAH2460 | 2 | 14.4 | 20 | 30~150 | ≤400 | 645~1500 | 708 | 30 | 6091*3925*3846 | |