Suzhou Vanforge Metals Co., Ltd. |

|

15NiCuMoNb5-6-4 PRESSURE VESSEL STEEL is a weldable fine grained steel which is characterized by high yield strength at elevated temperatures. 15NiCuMoNb5-6-4 PRESSURE VESSEL STEEL is produced using basic oxygen steelmaking process. Its properties are achieved by normalizing and tempering or, for thicknesses exceeding 100 mm by normalizing and tempering or water quenching and tempering.

15NiCuMoNb5-6-4 PRESSURE VESSEL STEEL is used as plate or formed part for boilers, pressure vessels, piping and other fabricated parts operating at temperatures up to 500 °C.

Product description

Range of application

15NiCuMoNb5-6-4, Material No. 1.6368, is standardized in EN 10028, part 2, for thicknesses

up to 200 mm and qualified in accordance with VdTÜV material data sheet 377/1 for the application range of the AD 2000-Merkblätter in thicknesses up to 180 mm.

Applications:

- Boilers in accordance with EN 12952/ EN12953 (TRD 101) for temperatures up to 500 °C.

- Pressure vessels in accordance with AD 2000-Merkblatt W1, HP 8/1, EN 13445 and CODAP 2005 for temperatures from -20 °C up to 500 °C.

This data sheet applies to heavy plates with thicknesses from 6 to 250 mm.

Chemical analysis in %

For the ladle analysis the following limiting values are applicable:

| C | Si | Mn | P | S | N | Al | Ni | Cu | Mo | Nb | Cr |

| ≤0.19 | 0.20-0.56 | 0.75-1.30 | ≤0.030 | ≤0.013 | ≤0.022 | ≥0.010 | 0.90-1.40 | 0.40-0.90 | 0.22-0.54 | 0.005-0.055 | ≤0.35 |

Fully killed, fine grained steel with metallurgical treatment in the ladle.

Delivery condition

thicknesses ≤ 100 mm normalized and tempered

thicknesses > 100 mm normalized and tempered or water quenched and tempered

In accordance with EN 10028-2 a water quenching and tempering treatment is already possible for thicknesses equal or superior to 100 mm.

If the heat treatment is to be performed during processing, the plates can be delivered in the normalized condition, and in exceptional cases in the as rolled condition by special agreement before the order. In this case testing of the mechanical properties is provided on the basis of simulated heat treated specimens.

Mechanical properties in the delivery condition (heat treated condition)

Tensile test at ambient temperature (transverse test specimens)

| Plate thickness | Yield strength ReH | Tensile strength Rm | Elongation A5 |

| [mm] | [MPa], minimum | [MPa] | %, minimum |

| ≤ 40 | 460 | 610-780 | 16 |

| > 40 ≤ 60 | 440 | 610-780 | 16 |

| > 60 ≤ 100 | 430 | 600-760 | 16 |

| > 100 ≤ 150 | 420 | 590-740 | 16 |

| > 150 ≤ 200 | 410 | 580-740 | 16 |

| > 200 ≤ 250 | 400 | 580-740 | 16 |

For plate thicknesses ≥ 15 mm, the fulfilment of one of the three quality classes Z15, Z25 or Z35 in accordance with EN 10164 or similar standards can be stipulated on the order.

Tensile test at elevated temperature (transverse specimens in accordance with 10028-2)

| Plate thickness | Minimum yield strength Rp0,2 [MPa] at test temperature | |||||||

| [mm] | 100 °C | 150 °C | 200 °C | 250 °C | 300 °C | 350 °C | 400 °C | 450 °C |

| ≤ 40 | 420 | 415 | 403 | 391 | 380 | 366 | 351 | 331 |

| > 40 ≤ 60 | 410 | 397 | 385 | 374 | 363 | 350 | 335 | 317 |

| > 60 ≤ 100 | 401 | 388 | 377 | 366 | 355 | 342 | 328 | 309 |

| > 100 ≤ 150 | 392 | 379 | 368 | 357 | 347 | 335 | 320 | 301 |

| > 150 ≤ 200 | 382 | 370 | 359 | 349 | 338 | 327 | 313 | 295 |

| > 200 ≤ 250 | 373 | 361 | 350 | 340 | 330 | 318 | 305 | 288 |

Impact test with Charpy-V transverse specimens

| Test temperature [°C] | -20 | 0 |

| Minimum impact value [J] | 27 | 34 |

The specified minimum value is the average of 3 tests. Not more than one individual value is permitted to be below this minimum value and not more than 30 % below it. For plate thickness ≤ 11 mm the test can be carried out on Charpy-V specimens or Charpy-V-type specimens with reduced width. The minimum impact value will be reduced proportionally to the reduction of the specimen’s cross section.

Unless otherwise agreed, the test is only performed at -20 °C. If the order is placed also in accordance with VDTÜV material data sheet 377/1 the test is only performed at 0 °C. Upon agreement lower test temperatures or higher minimum impact values as e.g. 40J in accordance with EN 10028-2 can be confirmed.

Long time properties at elevated temperatures

The table below shows preliminary guidance data on creep strain limit and creep rupture strength. The specified values represent the average of the scatter band known to date.

| Temperature [°C] | Strength for 1% (plastic) creep strain [MPa] | Creep rupture strength [MPa] | ||

| 100,000 h | 1,000,000 h | 100,000 h | 1,000,000 h | |

| 400 | 324 | 294 | 402 | 373 |

| 410 | 315 | 279 | 385 | 349 |

| 420 | 306 | 263 | 368 | 325 |

| 430 | 295 | 245 | 348 | 300 |

| 440 | 281 | 227 | 328 | 273 |

| 450 | 265 | 206 | 304 | 245 |

| 460 | 239 | 180 | 274 | 210 |

| 470 | 212 | 151 | 242 | 175 |

| 480 | 180 | 120 | 212 | 139 |

| 490 | 145 | 84 | 179 | 104 |

| 500 | 108 | 49 | 147 | 69 |

Testing

Sampling, testing method and tests are in accordance with the provisions in EN 10028. For orders in accordance with VdTÜV material data sheet 377/1, the conditions indicated there are respected. Additional tests can be agreed upon. The plates are delivered with inspection certificate 3.1 or 3.2 in accordance with EN 10204. The document type and, in case of inspection certificate 3.2, the inspection representative are to be stated on the order.

Identification of plates

Unless otherwise agreed the marking is carried out via low stress steel stamps with at least the following information:

• steel grade (15NiCuMoNb5-6-4 PRESSURE VESSEL STEEL)

• heat number

• number of mother plate and individual plate

• the manufacturer's symbol

• inspectors' sign

Fabrication properties

The entire processing and application techniques are of fundamental importance to the reliability of the products made from this steel. The user should ensure that his design, construction and processing methods are aligned with the material, correspond to the state-of-the-art that the fabricator has to comply with and are suitable for the intended use. The customer is responsible for the selection of the material. The recommendations in accordance with EN 1011-2 should be observed.

Forming properties and weldability

15NiCuMoNb5-6-4 PRESSURE VESSEL STEEL can be hot or cold formed and can be welded and flame cut according to the general procedures. The guidelines given in EN 1011 (Welding), CEN/TR 10347 (Guidance for forming of structural steels in processing) as well as the provisions of VdTÜV-material data sheet 377/1 shall be observed.

Heat treatment

| Austenitizing/Cooling/Tempering 1) | Stress relieving | |

| • Austenitizing: 880-940 °C | 580-620 °C 2) | |

• Cooling: After temperature equalization (880-940 °C) over the whole section cooling in air or water according to plate thickness.

• Tempering: 640-680 °C After equalization over the whole section holding time at least 30 min. Cooling in still air. | Thickness (t) [mm] | Time [Minutes] |

≤ 15 > 15 ≤ 60 > 60 | ≥ 30 ≥ 2 x t 120

| |

| Cooling in still air | ||

If stress relieving and tempering are joined together in one process, the tempering conditions apply.

General technical delivery requirements

Unless otherwise agreed, the general technical delivery requirements in accordance with EN 10021 apply.

Tolerances

Unless otherwise agreed, tolerances are in accordance with EN 10029, with class B for the thickness and class N for the flatness.

Surface condition

Unless otherwise agreed, the provisions in accordance with class B2 of EN 10163-2 are applicable.

General notes

If special requirements, which are not listed in this material specification, are to be met by the steel due to its intended use or processing, these requirements are to be agreed before the order.

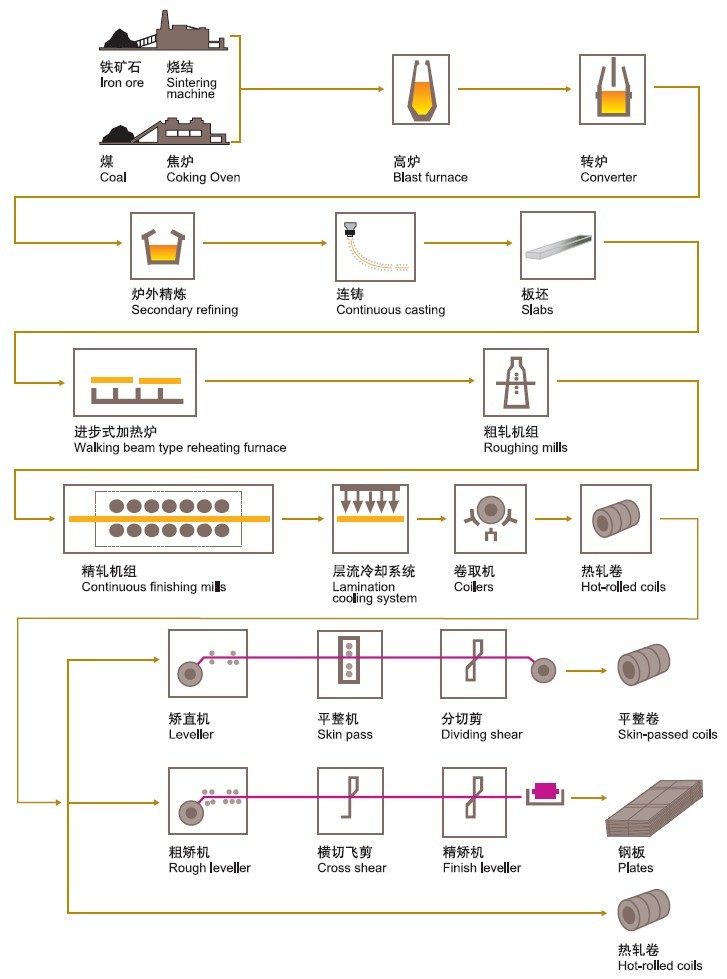

Production process