Phoenix (suzhou) electronic Co.,ltd |

|

3V 20MA 0.2W 2016 20-30LM 2700-6000K PPA SMD LED CHIP USED FOR

MOBILE CAMERA LIGTING AND HOME APPLIANCE DISPLAY

automobile:

Viewing angle:120 deg

Ø The materials of the LED dice is InGaN

Ø 2.2mm*1.6mm*0.6mm

Ø RoHS compliant lead-free soldering compatible

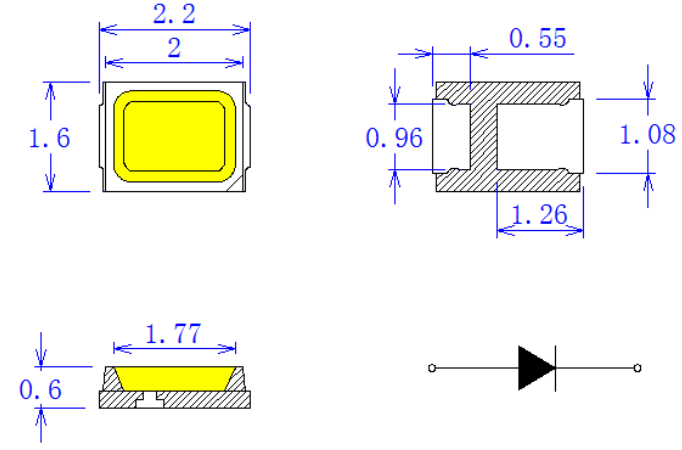

2. Package Structure:

Unit: mm Tolerance: +/-0.2mm

Figure: 0.2W medium power thin series circuit diagram

Tolerance: ±0.2mm unless otherwise noted

Electrodes: Ag Plating Copper Alloy

Encapsulating Resin: Silicon Resin

Package: Heat-Resistant Polymer

3. Electro-Optical Characteristics: (Each LED @ 60mA, Ta 25℃ )

| Product No. | Material | VF(V) | Color | RA | Flux(lm) | ||

| min | max | CIE coordinates x, y | min | max | |||

| QT-2016ZW-1CSAZ | InGaN | 2.8 | 3.5 | Typ x=0.33, y=0.33 | 80 | 85 | 28 |

4. Product Specification:

| Item | Specification | Material | Quantity |

| Chip | InGaN | InGaN | 1 in 1 |

| Reflector | White | PPA | |

| Frame | C2680 | Silver-Plated Copper | |

| Gold wire | 0.9mil | Alloy | |

| Phosphor | Yellow | YAG | |

| Encapsulant | MilkyWhite | Resin | |

| Carrier tape | According to EIA 481-1A specs | Conductive black tape | 4000pcs per reel |

| Reel | According to EIA 481-1A specs | Conductive black | 4000pcs per reel |

| Label | Repsn standard | Paper | |

| Packing bag | 220x240mm | Aluminum laminated bag/ no-zipper | One reel one bag |

| Carton | Repsn standard | Paper | Non-specified |

5. Absolute Maximum Ratings:

| Item | Symbol | Absolute Maximum Ratings | Unit |

| Forward Current | IF | 60 | mA |

| Reverse Voltage | Vr | 5 | V |

| Pulsed Forward Current | IFP* | 90 | mA |

| Power dissipation | PD | 0.2 | W |

| Operating Temperature | TOP | -40~85 | ℃ |

| Storage Temperature | TST | -40~85 | ℃ |

| Electrostatic Discharge | ESD | 2000(HBM) | V |

| Junction Temperature | Tj | 110 | ℃ |

| LED Thermal resistance | Rth s-j | 27 | ℃/W |

6. Typical Electro-Optical characteristics curves:

7. LED Reliability Test List:

| Test Item | Test Conditions | Standard | Qty(Pcs) |

| Life Test | 25℃,1000Hrs@60mA | / | 22 |

| High Temperature | 85℃,1000Hrs@60mA | / | 22 |

| Low Temperature | -40℃,1000Hrs@60mA | / | 22 |

| High Humidity Heat | 85℃,85%RH, 1000Hrs@60mA | / | 22 |

| Low Temperature Storage | -40℃,1000Hrs | JEITA ED-4701 200 202 | 22 |

| High Temperature Storage | 100℃,1000Hrs | JEITA ED-4701 200 201 | 22 |

| Temperature Cycle | (-40'C 30mins --25'C(5mins)--100'C(30mins) ,Temp changing rate:3+/-0.6'C/min) | JEITA ED-4701 100 105 | 22 |

| Thermal Shock | -40'C(15mins) --100'C(15mins),changing time <5mins ,300C | MIL-STD-202G | 22 |

| Pulse Life Test | Tp=1ms,DC=0.1,D=Tp/T @ 3×60mA,1000Hrs | / | 22 |

| ESD Test(HBM) | 2000V,200V/Step, Forward & Reverse Test both 3times | AEC (Q101-001) | 22 |

| Soldering Resistance | 260±5℃,10S,3times Pre-treatment 30℃,70%RH | JEITA ED-4701 300 302 | 22 |

| Reflow IV Decay | 260±5℃,10S,1time Pre-treatment 30℃,70%RH,168Hrs | / | 22 |

| Judgment Criteria | |||

| Forward Voltage VF | VF Max-Increase < 1.1x | ||

| Reverse Current IR | IR Max-Increase < IRmax | ||

| Luminous Intensity IV | IV Decay < 40% | ||

| ※Solder ability test criteria:coverage is not less than 95% | |||

| Note:Measurement shall be taken after the tested samples have been returned to normal ambient conditions (generally after two hours) | |||

8. Cautions:

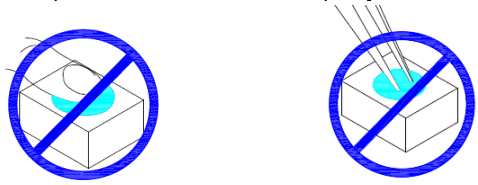

The encapsulated material of the LEDs is silicone. Therefore the LEDs have a soft surface on the

Top of package. The pressure to the top surface will be influence to the reliability of the LEDs. Precautions Should be taken to avoid the strong pressure on the encapsulated part. So when use the picking up nozzle,The pressure on the silicone resin should be proper.

8.1: Soldering iron :

8.1.1 When hand soldering, the temperature of the iron must less than 300℃ for 3 seconds.

8.1.2 The hand solder should be done only one times

8.2: SMT Reflow Soldering Instructions SMT:

8.2.1 Reflow soldering should not be done more than two times;

8.2.2 When soldering , do not put stress on the LEDs during heating;

8.2.3 The recommended reflow soldering profile as following:

8.3 Handling Precautions

8.3.1 Handle the component along the side surface by using forceps or appropriate tools;

8.3.2 Do not directly touch or handle the silicone lens surface. It may damage the internal circuitry;