Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Hongtai Refractory are a renowned manufacturer engaged in offering

Magnesite Bricks to the clients. Our offered bricks are

manufactured under supervision of our skilled professionals using

the best quality materials. Moreover, in accordance with the

international quality standards, these bricks are stringently

checked on various parameters.

The Magnesite brick is one of the most widely used basic refractory

bricks. Different grade magnesite used as raw materials are applied

in Magnesia bricks with various quality.

Magnesite Bricks features:

High temperature, high temperature resistance, anti-erosion

Magnesite Bricks uses:

1.The regenerative chamber for the ceramic frit kiln, sodium

silicate and glass furnace

2.The furnace lining of iron and steel industry, such as

ferroalloys furnace, metal mixer

3.The non-ferrous metallurgy industrial furnace lining, such as the

furnace copper, lead, zinc, tin, etc

4.Calcining kiln, shaft kiln and tunnel kiln for refractory

material industry

5.The lining for cement rotary kiln

Glass kiln regenerator used Magnesia refractory bricks

Index | MZ-89 | MZ-91 | MZ-95 | MZ-97 |

MgO % ≥ | 89 | 91 | 94.5 | 96.5 |

CaO % ≤ | 3 | 2.5 | 2.0 | 1.5 |

Apparent Porosity % ≤ | 20 | 18 | 17 | 16 |

Cold Crushing Strength Mpa ≥ | 50 | 60 | 65 | 70 |

Initial Soften Temperature 0.2Mpa ℃≥ | 1540 | 1550 | 1620 | 1700 |

Reheating linear change(%)1650℃ 2h≤ | 0.6 | 0.5 | 0.4 | 0.4 |

Our main types of high alumina bricks as follows:

General usage high alumina bricks: SK32,SK34,SK36,SK38,SK40

High alumina brick for blast furnace: GL-65, GL-55, GL-48

High alumina brick for hot blast stove: RL-65, RL-55,

RL-48(common type)

DRL-155, DRL-150, DRL-145, DRL-140, DRL-135, DRL-130, DRL-127(Low

creep)

High alumina brick for EAF in steel-making: DL-80, DL-75,

BDL-80, BDL-75

High alumina brick for steel ladle lining: CL-55, CL-65, CL-75

High alumina brick for cement kiln: Spalling resistant high

alumina brick: GKBL-70, KBL-70

Phosphoric acid immersed high alumina brick: PLZ-75, PALZ-77

Silicon-mullite brick: SMLZ-60

High alumina brick for resistance furnace: RLZ-65, RLZ-55, RLZ-48

Andalusite brick for anode baking in aluminium smelting: HLZ-45,

HLZ-60

Andalusite brick for hot blast stove: HLZ55, HZL62, HLZ65

Silicon brick: SLZ-62 Mullite brick: MLZ-72

Mullite corundum brick: MCLZ-80, MSLZ-80

Various size and shape are available, we can produce according to

your drawings.

Packaging of magnesia refractory bricks

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm.

2.Load weight of each pallet: 1.5-2.0 tons.

3. 40 x 25kg plastic woven bags on pallet.

4. 40 x 25kg paper bags on pallet.

5. According to client's special requirement

Shipping of magnesia refractory bricks

1.Our packaging is as per customer's request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity

guaranteed, and also in accordance with the contract and customer's

requirment completely.

1)Raw material to factory→checkout→burdening→stirring→mixing→taking

out the raw material,

2)Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and

Shipment.

2.Quality Assurance

1)Going out the furnace→checkout→packing→qualified product→putting

in storage→sale,

2)The process from raw to product are strictly tested by equipment.

1.Inspection and Control of incoming raw materials: according to

the chemical content,raw materials are classified into different

levels to ensure quality of brick first.

2.Inspection and control of the process: during the

production,every brick will be weighed twice strictly to reduce the

error of weight .

3.Quality audit by quality management: inspection of product

standardization of quality of each product by process control and

experimentation, taking corrective measures timely whenever

deviations are noted.

4.Before delivery, the inspectors will inspect the size,appearance,

physical and chemical properties of brick again in factory.

Hongtai Refractory is professional in manufacturing various types of refractory bricks and raw materials.

Abundant resources and work experience supply high quality product.

Professional and timely service to give you the best guarantee.

1. Strong professional:

Our company has thirty years producing experience in refractory

product. Our manager will supervise on a various refractory' s

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

The main products are:

1)Al2O3-SiO2 series of products: including silica mullite brick,

high al brick resistant to spalling, low porosity fire clay bricks.

fire clay and high alumina, corundum, phosphate high alumina

bricks, brick resistant to aikali, brick resistant to acid, silicon

carbide products, etc.

2)A series of basic bricks including environmental protection

composite brick, toughness composite brick, direct bonded magnesia

chrome brick, modified direct bonded magnesia chrome bricks,

iron-magnesia composite spinel brick.iron-magnesia spinel,

Magnesite Checker Refractory Brick Used for Glass

Kiln,periclase-spinel brick. MgO-Al2O3 spinel brick, fused

rebounded magnesia-chrome birck. fused semi-rebonded

magnesia-chrome brick, AZS brick, refractory ball, etc.

3)Un-shape products including chemical electric power,

metallurgical, building materials fields with all kinds of ramming

material, low cement castable, high Strength Alumina materials,

high strength steel fiber reinforced castable, castable resistant

to alkali corundum castable. mullite castable, ceramic coal and

paint resistant to wear, gunning refractory mix. etc.

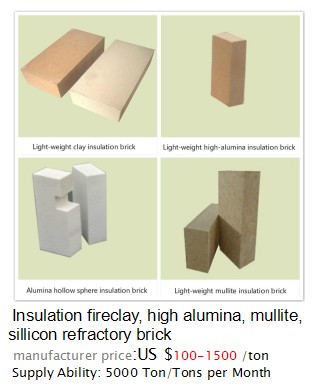

4)Insulation materials Including high alumina heat insulation

brick, mullite heat-insulation bricks, fire clay insulation brick,

alumina hollows ball brick, light weight heat-insulation castable

and various types of calcium silicate Board, ceramic fiber board

and blanket etc.

3. Annual exports:

Now we have gained a global sales network reaching Taiwan, Russia,

Mongolia, South Korea, Vietnam, Pakistan, Bulgaria, Finland,

Greece, Spain, Congo, Angola, South Africa, and Maldives, Jordan

and so on. The export figure is more than USD 4 million.

4. Production equipment:

Production and testing equipments are new, complete and automated

or semi- automated. Such modern facilities and equipments have

provided the fine technical guarantee for the production and

testing.

5. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

1. How can I get your prompt quotation?

We can give you reply with quotation quickly if you kindly send the

inquiry with the detail, such as the quantity, the specifications

and the application of the products.

2. What is the MOQ (minimum order quantity)?

100 pcs is OK.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don't conform to customer's samples or have quality

problems, our company will be responsible to make compensation for

it based on enough evidences.

7. How can I contact you?