Changzhou DLX Alloy Co., Ltd. |

|

Verified Suppliers

|

|

Inconel X-750 alloy is a nickel based high-temperature alloy that has good corrosion resistance and oxidation resistance below 980 ℃, high strength below 800 ℃, good relaxation resistance below 540 ℃, as well as good formability and welding performance.

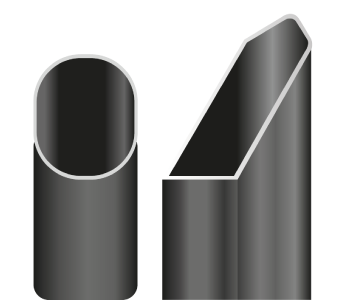

This alloy is mainly used to manufacture plane springs and coil springs with high strength and resistance to relaxation for aircraft engines operating below 800 ℃. It can also be used to manufacture parts such as turbine blades for steam turbines. The available varieties include plate, strip, bar, forging, ring parts, wire, and pipe.

1. Raw material preparation: High-purity nickel alloy is selected as the raw material, ensuring

it meets specific chemical composition and quality standards.

2. Mixing and batching: The high-purity nickel alloy is mixed with other alloying elements

according to a predetermined formula. These alloying elements may

include chromium, iron, aluminum, titanium, etc.

3. Melting: The mixed raw materials are placed in a high-temperature furnace

to melt into alloy liquid. During this process, it is ensured that

the desired chemical composition and uniform mixing are achieved.

4. Casting: The molten alloy liquid is poured into pre-designed molds to form

pipes of the required size and shape. Control at this stage is

crucial for the final product's performance.

5. Heat treatment: The cast pipes undergo heat treatment. This step aims to adjust

the grain structure and improve the mechanical properties of the

material. Common heat treatments include aging and solution

annealing.

6. Cooling and Cutting: The heat-treated pipes are cooled and then cut to the desired

lengths. It is ensured that the cutting process does not adversely

affect the properties of the pipes.

7. Surface Treatment: Necessary surface treatments such as polishing, cleaning, or other

surface coatings are performed to meet specific customer

requirements.

8. Final Inspection: Comprehensive quality inspection is conducted on the produced

Inconel X-750 alloy pipes. This includes visual inspection,

chemical composition analysis, mechanical property testing, etc.,

to ensure the product meets standard requirements.

9. Packaging and Shipping: The inspected alloy pipes are packaged to prevent damage during

transportation. Product specifications, quality certifications,

etc., are indicated, and shipping arrangements are made.

| Element | Ni +Co | Cr | Nb | Ti | C | Mn | Si | Cu | Al | S | Iron |

| Chemical Composition (%) | 70% Min | 14%- 17% | 0.7%- 1.2% | 2.25%- 2.75% | 0.08% max | 1% max | 0.5% max | 0.30% max | 0.4%-1.0% | 0.01% max | 5%-9% |

1. Aerospace Industry: Inconel X-750 alloy pipes are widely used in the aerospace industry

for manufacturing components of aircraft engines, such as turbine

blades, combustion chambers, and jet pipes. Its high-temperature

strength and excellent corrosion resistance make it an ideal

material for these critical components.

2. Energy Sector: In the energy sector, Inconel X-750 alloy pipes are commonly

used for manufacturing high-temperature and high-pressure equipment

for oil and gas extraction, such as well pipes, valves, and oil

& gas pipelines. Its corrosion resistance and high-temperature

strength enable it to operate stably in harsh working environments

for extended periods.

3. Chemical Industry: Due to its outstanding corrosion resistance, Inconel X-750

alloy pipes are also widely used in the chemical industry for

manufacturing chemical reactors, steam generators, and

high-temperature reaction equipment.

4. Nuclear Industry: In the nuclear industry, Inconel X-750 alloy pipes are used

for manufacturing components of nuclear reactors, such as reactor

pressure vessels, fuel elements, and heat exchangers. Its

high-temperature strength and radiation resistance make it an ideal

material for nuclear equipment.

| AMS Number | Alloy | Type | UNS | Cross Ref. Spec | Misc./Shape | |

|---|---|---|---|---|---|---|

| AMS 5542 Custom Tube | Inconel X750 | Nickel | N07750 | - | Custom Tube |  |

| AMS 5542 Plate | Inconel X750 | Nickel | N07750 | - | Plate |  |

| AMS 5542 Sheet | Inconel X750 | Nickel | N07750 | - | Sheet |  |

| AMS 5542 Strip | Inconel X750 | Nickel | N07750 | - | Strip |  |