Zhengzhou Zhengtong Abrasive Import&Export Co.,Ltd |

|

Verified Suppliers

|

|

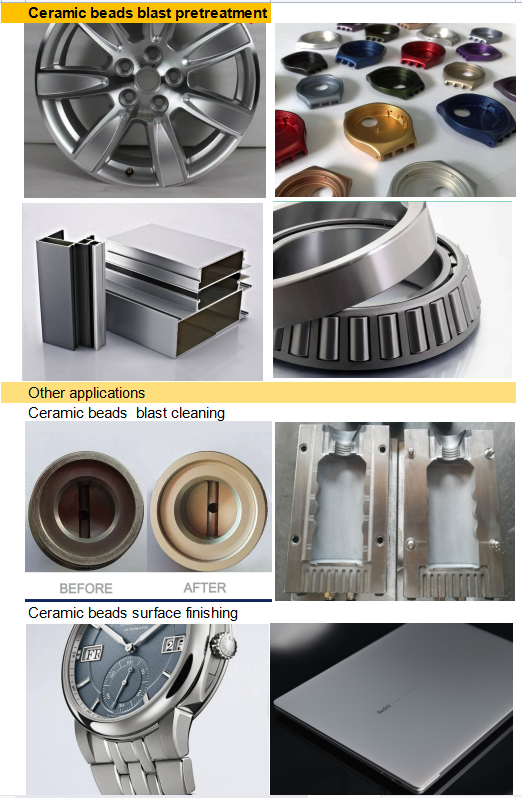

Ceramic Beads Blasting Media for metal blast pretreatment before coating / plating

DESCRIPTION

Ceramic beads also called ceramic media, ceramic bead blasting media, or ceramic blasting beads.

It is of high hardness, good elasticity, high gloss and high impact strength. Ceramic blasting beads

mainly used for blast cleaning, debluring, removing oxice layers of castings and forging parts, also

for metal surface finishing, and pretreatment before coating and plating.

SPECIFICATION

| Chemical Index | ZrO2 | SiO2 | Al2O3 |

| 60-65% | 25-30% | 7-13% | |

| Typical Value | 62.20% | 26.10% | 9.05% |

| Bulk Density | 2.3g/cm3 | ||

| Specific Density | 3.85g/cm3 | ||

| Vickers Hardness | 700HV | ||

| Grit size | B20 | B30 | B40 | B60 | B80 | B100 | B120 |

| Microns μm | 600-850 | 425-600 | 250-425 | 125-250 | 180-250 | 125-180 | 63-125 |

| Grit size | B125 | B170 | B205 | B400 | B505 | Special sizes like B150 can be customized | |

| Microns μm | 0-125 | 45-90 | 0-63 | 30-63 | 0-63 | ||

| Grit size | Z850 | Z600 | Z425 | Z300 | Z210 | Z150 | Z100 |

| Microns | 850-1180 | 600-850 | 425-600 | 300-425 | 210-300 | 150-210 | 100-150 |

APPLICATION

Ceramic beads can be used for blast pretreatment beforecoating or plating.

Among all surface cleaning methods, the ceramic beads sandblasting

method is a thorough, universal, and extensive method, because:

1. Sandblasting is more efficient, thorough and cheaper than other

pretreatment processes.

2. The sandblasting process allows you to freely choose the

cleanliness and roughness of your workpiece.

Sandblasting with ceramic beads can produce a uniform and

uneven rough surface on the cleaned surface to facilitate

mechanical bonding of the coating. Using clean compressed air to

drive clean ceramic sand to spray on the surface of the workpiece

can generate compressive stress on the surface of the substrate,

remove the surface oxide film, and cause lattice distortion of part

of the surface metal, which is conducive to the physical bonding of

the coating. The substrate metal can be sandblasted to obtain a

clean, rough and highly reactive surface. This is an important

preprocessing method.

The quality of the pre-treatment of the sandblasting process affects the adhesion, appearance, moisture resistance and corrosion resistance of the coating. If the pretreatment work is not done well, the rust will continue to spread under the coating, causing the coating to fall off in pieces.

APPLICABLE EQUIPMENT

Manual sandblasting machine

Automatic sandblasting machine

Open type sandblasting machine

Sandblasting machine room

CONTACT US

No matter you’re the end users, blasting service suppliers, sandblasting equipment dealers or ceramic

blasting media and other blasting abrasive distributors, welcome to contact us. More details of ceramic

blasting beads, updated prices and samples will be available.