Zhengzhou Zhengtong Abrasive Import&Export Co.,Ltd |

|

Verified Suppliers

|

|

Iron-free Ceramic Bead Blasting Media JZB205 for Medical Implant Surface Finish

1. Product Description of Ceramic Blasting Media

Ceramic beads is also called as ceramic blasting media,it selects the high quality imported zircon sand

as main raw material. It has the outstanding characteristics of high hardness, good wear resistance and

low-break down rate, it is especially suitable for metal surface finishing,it can be matched with all kinds

of air and wet blasting equipments.

2. Main Technical Data of Ceramic Bead Blasting

| Commodity Name | Chemical Index | Physical Index |

Ceramic Beads | ZrO2 60-66% SiO2 25-30% Al2O3 7-13% | Vickers Hardness ≥700 HV Bulk Density≥2.3g/cm3 True Gravity: 3.85g/cm3 Process: Melting |

| Particle Size for Ceramic Blasting Media | ||

| B20: 600-850μm | B120: 63-125μm | |

| B30: 425-600μm | B150:0-125μm | |

| B40:250-425μm | B170: 45-90μm | |

| B60:150-300μm | B205: 0-63μm | |

| B80:125-212μm | B400: 30-63μm | |

| B100:106-180μm | B505: 10-30μm | |

| Special size can be customized accordingly. | ||

3. Main Applications of Ceramic Beads

B20,B30: Metal surface sandblasting

B40: Mould surface cleaning for glass bottle

B60: Sandblasting for inner and outer walls of precision steel pipe,

B80:Surface finishing for watch case

B100: Surface cleaning for Titanium alloy bicycle frame

B120: Surface finishing for Golf head

B170: Suface finishing for Iphone metal surface and its built-in parts

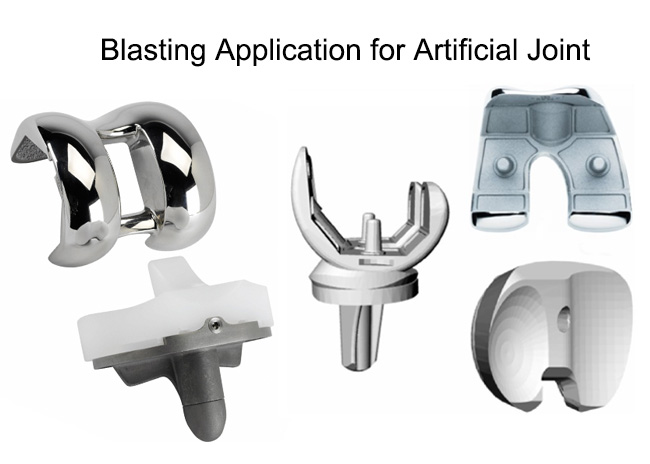

B205: Roughening for dental implant,hib&knee implant,finishing gear...

4. Why ceramic beads can replace glass beads in blasting applications?

Firstly,ceramic beads can be recycled for many times,its service life can be prolonged for at least 20 times

compared with the one of glass beads;

Secondly,ceramic beads has higher density and lower break-down rate,which can finally achieve one more

brighter and consistent visual blasting effect;

Thirdly,ceramic beads will provide one clean and brighter blasting working condition,no hidden dangers of

silicosis for the worker.

Fourthly,little dust generated in the whole blasting process,which will finally reduce the treatment cost of

solid waste.

Therefore ,ceramic beads can replace glass beads where one clean working condition and more consistent

blasting effect is required.

5. Why choose us?

Professional manufacturer of ceramic beads,annual output over 3000mts;

Stricter quality control system,each step can be traced from the raw material to finished products;

All shipment will be sampled and tested in twice even for one small sample;

Professional sales and technical staffs,providing 7*24hrs service support;

Quick response and fast delivery;

Products are exported to USA,Canada,U.K.,New Zealand,Poland,Germany,Australia,India,Vietnam,South Korea,Singapore,Malaysia,Philippines...