Shenzhen Bwin Precision Tools Co., Ltd. |

|

Feature

Description

Specifications

| Brand | BWIN |

| Model | SDMT20512 |

| Color | Colorful |

| Workpiece | Cast iron/Steel/Stainless steel |

| Type | SDMT 1205 milling tool insert |

| Material | Tungsten Carbide Muti Face Milling Inserts |

| Processing Type | Medium Cutting |

| Feature | Excellent substrate |

| Strong universality | |

| Smooth cutting | |

| Anti collapse and wear resistance | |

High smoothness | |

| Standard | ISO |

| Quantity | 10pcs/box |

| Weight | 0.015kg |

| Package | Plastic Box |

| Customized Support | OEM, ODM |

Lead Time

| antity(pieces) | 1 - 3000 | >3000 |

| Lead time (days) | 7 | To be negotiated |

Notice

Applications

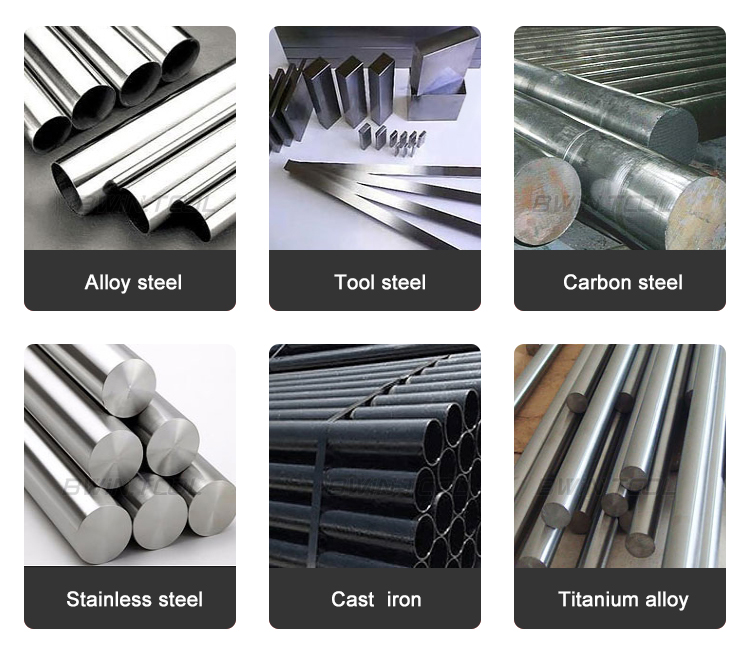

Our milling carbide inserts could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following:

Advantages

1. Flank Wear?

Higher cutting resistance,Notch wear on flank,Poor roughness of

surface, or deterioration of accuracy.

Soft grades,Excessive cutting speed,Small flank angle,Low feed.

Select a higher,wear-resistant grade,Reduce cutting speed,Increase

flank angle,Increase feed.

2. Crater Wear?

Uncontrolled chip,Poor surface quality,when finishing High speed

processing carbon steel

Soft grades,Excessive cutting speed,Excessive feed,The strength of

chip breaker Insufficiet.

Change to a higher wear-resistant grade,Reduce cutting speed,Reduce

feed,Select a higher strength chip breaker.

3. Chipping?

Sudden fracture of cutting edge(rake face and flank),Instability

insert life

Toughness insufficient,Excessive feed rate,Strength of cutting edge

insufficient,Instability of the tool.

Select a tougher grade,Decrease feed rate,Increase honing of

cutting edge(chamfering to rounding),Increase the stability and

setting angle

4. Insert Fracture?

Cutting resistance increased Poor surface roughness.

Toughness insufficient,Excessive feed rate,Strength of cutting edge

insufficient,Instability of the tool.

Select a tougher grade,Decrease feed rate,Increase honing of

cutting edge(chamfering to rounding),Increase the stability and

setting angle.