Shenzhen Bwin Precision Tools Co., Ltd. |

|

CHaracteristic:

High quality tungsten steel raw material

New coating process

Sharp edge

Smooth chip removal

Good shockproof performance

Description:

HRC45 2 flute flat end mill uses high-quality wear-resistant raw materials, 0.6-0.8UM ultra-fine grains, with concentrated particle size distribution, excellent wear resistance, and can greatly improve tool life; The blade is coated with TLALN coating. All kinds of steel parts, such as mold steel, alloy steel, stainless steel, cast iron, and materials below HRC45 °, can be processed easily and directly from high-speed rough processing to fine processing. Chamfering, easy to use, is a versatile milling cutter for high hardness and high speed cutting applications. The super-large capacity cutting groove has powerful cutting, and the discharge cutting is more smooth, which can achieve high efficiency processing, and the workpiece is more precise and shiny.

Milling parameters:

HRC45 2F Carbide Flat End Mill | Tool length | fz&v | |||||

Short | 1 | ||||||

Long1 | 0.9 | ||||||

Overlength | 0.8 | ||||||

Speciality | 0.6 | ||||||

Type | Material | Strength N/mm²

Hardness HRC | Cooling | ||||

Air | Dry cutting | Lubricating fluid | |||||

P | PI | P1.1 | Non alloy structural steel, free cutting structural steel, carburized steel and quenched and tempered steel | <700 | √ | √ | √ |

P1.2 | quenched and tempered steel | <1200 | √ | √ | √ | ||

P2 | P2.1 | Alloyed nitrided steel, carburized steel and quenched and tempered steel | <900 | √ | √ | √ | |

P2.2 | Tool steel, bearing steel, spring steel and high-speed steel | <1400 | √ |

| √ | ||

P3 | P3.1 | Tool steel, bearing steel, spring steel and high-speed steel | <900 | √ | √ | √ | |

P3.2 | Tool steel, bearing steel, spring steel and high-speed steel | <1500 | √ |

| √ | ||

| Sloting | |||||||||||

Vc | fz(mm/Tooth) | |||||||||||

Diameter | ||||||||||||

2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 | |||||

112 | 0.01 | 0.018 | 0.026 | 0.034 | 0.041 | 0.048 | 0.06 | 0.069 | ||||

92 | 0.01 | 0.017 | 0.025 | 0.032 | 0.038 | 0.045 | 0.056 | 0.065 | ||||

100 | 0.01 | 0.018 | 0.026 | 0.034 | 0.041 | 0.048 | 0.06 | 0.069 | ||||

72 | 0.009 | 0.015 | 0.022 | 0.028 | 0.034 | 0.04 | 0.05 | 0.058 | ||||

64 | 0.01 | 0.018 | 0.025 | 0.032 | 0.039 | 0.045 | 0.057 | 0.066 | ||||

56 | 0.009 | 0.016 | 0.023 | 0.029 | 0.036 | 0.041 | 0.052 | 0.06 | ||||

| Roughing | |||||||||||

Vc | fz(mm/Tooth) | |||||||||||

Diameter | ||||||||||||

2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 | |||||

228 | 0.018 | 0.031 | 0.045 | 0.057 | 0.070 | 0.081 | 0.101 | 0.118 | ||||

208 | 0.017 | 0.029 | 0.042 | 0.054 | 0.065 | 0.071 | 0.095 | 0.11 | ||||

184 | 0.018 | 0.031 | 0.045 | 0.057 | 0.070 | 0.081 | 0.101 | 0.118 | ||||

144 | 0.015 | 0.026 | 0.037 | 0.048 | 0.058 | 0.068 | 0.085 | 0.098 | ||||

132 | 0.017 | 0.03 | 0.042 | 0.054 | 0.066 | 0.077 | 0.096 | 0.112 | ||||

112 | 0.015 | 0.027 | 0.039 | 0.05 | 0.060 | 0.07 | 0.088 | 0.102 | ||||

| Finish | ||||||||||

Vc | fz(mm/Tooth) | ||||||||||

Diameter | |||||||||||

2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | ||

332 | 0.028 | 0.05 | 0.07 | 0.091 | 0.11 | 0.128 | 0.144 | 0.16 | 0.173 | 0.186 | |

272 | 0.026 | 0.046 | 0.066 | 0.085 | 0.103 | 0.12 | 0.135 | 0.15 | 0.162 | 0.173 | |

304 | 0.028 | 0.05 | 0.07 | 0.091 | 0.11 | 0.128 | 0.144 | 0.16 | 0.173 | 0.186 | |

212 | 0.023 | 0.041 | 0.059 | 0.076 | 0.092 | 0.107 | 0.121 | 0.134 | 0.145 | 0.155 | |

196 | 0.027 | 0.047 | 0.067 | 0.086 | 0.104 | 0.122 | 0.137 | 0.152 | 0.165 | 0.177 | |

168 | 0.024 | 0.043 | 0.061 | 0.079 | 0.095 | 0.111 | 0.125 | 0.139 | 0.150 | 0.161 | |

Note:

If the following carbide flat end mill cannot meet your requirements, we support OEM customized production. The diameter of 0.2mm to 25mm, the total length of 50mm to 200mm, 4F, 5F, 6F, 8F and logo can be customized, including inch size end milling cutter. Please contact us to select or customize non-standard carbide end mill according to your needs.

Specification | Flute Dia(φ) | Flute Length (C) | Shank Dia(D) | Overall Length(L) |

φ1*3*d4*50L | 1 | 3 | 4 | 50 |

φ1.5*4*d4*50L | 1.5 | 5 | 4 | 50 |

φ2*5*d4*50L | 2 | 5 | 4 | 50 |

φ2.5*7*d4*50L | 2.5 | 7 | 4 | 50 |

φ3*8*d4*50L | 3 | 8 | 4 | 50 |

φ4*10*d4*50L | 4 | 10 | 4 | 50 |

φ5*13*d6*50L | 5 | 13 | 6 | 50 |

φ6*15*d6*50L | 6 | 15 | 6 | 50 |

φ8*20*d8*60L | 8 | 20 | 8 | 60 |

φ10*25*d10*75L | 10 | 25 | 10 | 75 |

φ12*30*d12*75L | 12 | 30 | 12 | 75 |

φ14*45*d14*100L | 14 | 45 | 14 | 100 |

φ16*45*d16*100L | 16 | 45 | 16 | 100 |

φ18*45*d18*100L | 18 | 45 | 18 | 100 |

φ20*45*d20*100L | 20 | 45 | 20 | 100 |

Notice:

1. Please use equipment and fixtures with good rigidity and high precision.

2. Please select the cutting fluid applicable to the workpiece material.

3. During high-speed machining, avoid using cutting fluid with strong flammability.

4. When the used equipment cannot increase the speed, please reduce the feed speed and speed by the same proportion.

5. When clamping the flat end mill, please control the runout of the blade tip within 0.01mm.

Reminder:

The coating color will vary with the manufacturing batch, but the quality and performance will not be affected, so you can use it with confidence.

As the coating is non-conductive, please do not use conductive tool setting instrument.

Applications:

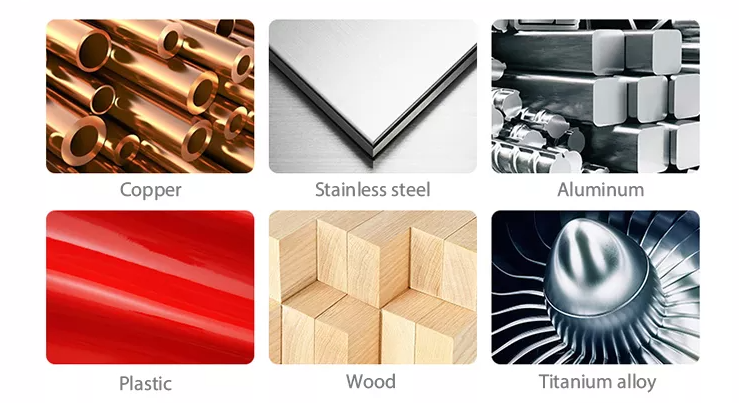

Pre-hardened Steel, stainless steel, Die steel, steel plate, Heat-resistant steel,pipe, copper and aluminum, cast iron, Nonferrous Metal, Wood, Plastic,FRP and sO on. General-purpose operation slotting, rilling, profiling.

FAQ

Q1. The tool breaks when cutting in or pulling out the workpiece

The feed rate and cutting depth can be reduced, and the cutting edge length can be shortened to the minimum of the necessary length.

Q2. Tool breaks during normal machining

Reduce the feed rate and cutting depth.

The tool shall be passivated.

Replace the clamp or spring collet.

The tool with high cutting edge number changes the tool with low cutting edge number to improve chip removal and prevent chip blockage.

Replace dry milling with wet milling (using cutting fluid), and use it with vortex tube gun to reduce tool temperature and avoid tool overheating.

If the wet milling fluid supply direction is changed from the front to the oblique rear or transverse top, the coolant flow should be sufficient.

Q3. The tool breaks when the feed direction changes

(1) Use arc interpolation (NC machine tool), or temporarily stop (temporarily) feeding.

(2) Reduce (decrease) the feed before and after the direction change.

(3) Replace the clamp or spring collet.

Q4. Problem: Part of the blade tip breaks

Chamfer the corners with manual grinding.

Change down milling to up milling.