Allwin Machine & Equipment Co.,Ltd |

|

Verified Suppliers

|

|

18.5kW 220V Higher Performance Silicon Carbide Ceramics For Water Base 20 Litre Horizontal Bead Mill With 1" Feed Pump

※ This Sand mills are main consists of chamber and disc dispersing system.

※ The double end mechanical sealing with independent technology could resistant to more than 1600 kinds of solvents.

※ The series have great flow rate and super fine discharging, the finally fineness can be reach 200-300nm for D90 .

※ The cooling efficiency is better than normal mills because the sectional double spiral water course is more beneficial to heat exchange. The grinding efficiency is higher 15-30% than traditional mill machines; the combined disperser can rapidly increase dispersing efficiency.

※ The materials of inner chamber is Silicon carbide Ceramic with higher production capacity and low temperature and keeping better color.

The main feactures:

1.Different materials could meeting different needs:

Adopted high abrasive-resisting materials: silicon carbide ceramics, like hard alloy, 9Cr18Mo alloy steel, SUS 304 stainless steel, to guarantee strengthen working life of bead mill machine. Meanwhile we suggest the suitable grinding beads to match with the inner chamber materials.

2. Decrease the temperature:

Applied self-owned double spiral cooling technology to enhance the space of heat rejection, with superior material with good thermal conductivity and lower the temperature before cooling come in pipe. Also temperature is lower if choose the inner chamber of Silicon carbide ceramics.

3. Strengthen the fineness:

The different fineness after grinding can be reached for your different demands, the smallest grinding media of 0.1mm with 200-300nm.

4. Enhance the efficiency:

High efficiency with energy saving, have grinding and dispersing technology, normally the efficiency is higher 10-30% than traditional machines. Also it's more better if choose the temperature is better.

The Technical Data

| No | main parameters | SP20 | Note |

| 1 | Non Explosion-proof motor kW | 18.5/22kW (Non Ex) | |

| 2 | Effective volume of grinding chamber (L) | 20 | |

| 3 | Water pressure (MPa) | 0.3 | |

| 4 | Cooling water consumption (L/min) | 2.5 -3m3/h | Advise offer the Cooling water less 10°C |

| 5 | Dimensions:L*W*H (mm) | 1940*900*1900 | |

| 6 | Weight (kg) | 1500 |

The Configuration instructions

| No | Main parts | SP 20 Non Ex-proof | Notes |

| 1 | Outter chamber | 304 stainless steel | |

| 2 | Inner chamber | Silicon Carbide Ceramics | |

| 3 | Dispersing shaft | 40Cr with hard chromium plating | |

| 4 | Dispersing disk | wear resistant steel | |

| 5 | Feeding and discharging end covers on the cylinder | 304 stainless steel | |

| 6 | Turbine centrifugal separator and pegs | 304 stainless steel and YG6 pegs | |

| eg | Static discharge screen ring | Wire Wound screen ring with 304.Gaps: 0.5mm. | |

| 8 | Mechanical seal | Intelligent double mechanical seal with mandatory lubricating-cooling system | |

| 9 | Feeding pump | 1.” ARO diaphragm pump; | |

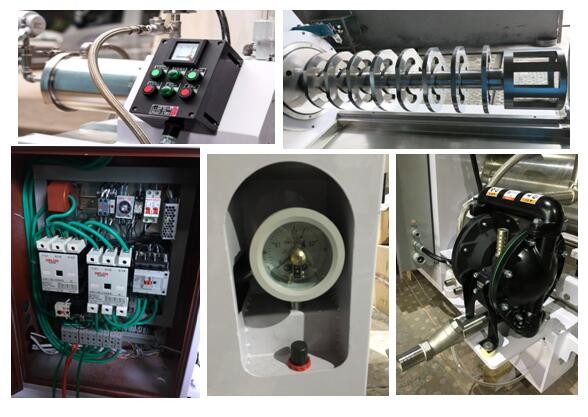

10 | Appliance configuration | Non Explosion-proof machine, suitable for water base materials, motor 55kW. Non Explosion-proof parts: operation column,electrical appliance boxes;electric contact pressure gauge, temperature,solenoid valves with NO ex electrical contacts., Control system (button type) | |

| 11 | Fasteners and connecting parts | Stainless steel clamp-type connecting parts | Quick and convenient |

The Application filed: Paint and Coating,Pigment and dyestuffs,Printing inks/ Digital inkjet ink,Gravure inks,Medicine and Cosmetics,Pesticide and Agrochemical industry,Food and food processing,Non-metallic minerals,HI-Tech nanometer products,Paper and Paper making chemical.

The After sales service:

1. Video instructions for installation and commissioning, if need, we will arrange engineer to your factory.

2. 12-24H feedback any customers questions, firstly offer the video help you solving, if need arrange maintenance engineer for you.

Also offered the related products: Dispersing machine & the Zirconical beads, This 2 products are much important for the Bead mills, this materials is pre-dispersing well, It's better for grinding with bead mill after pre-dispesing well. Also the zirconia beads (grinding beads with different size for meeting different finally fineness.

If need more detailed information and Price, please don't hesitate contact us, Also Warmly welcome to visit us.