Changzhou Taisheng Machinery Equipment Co.,Ltd. |

|

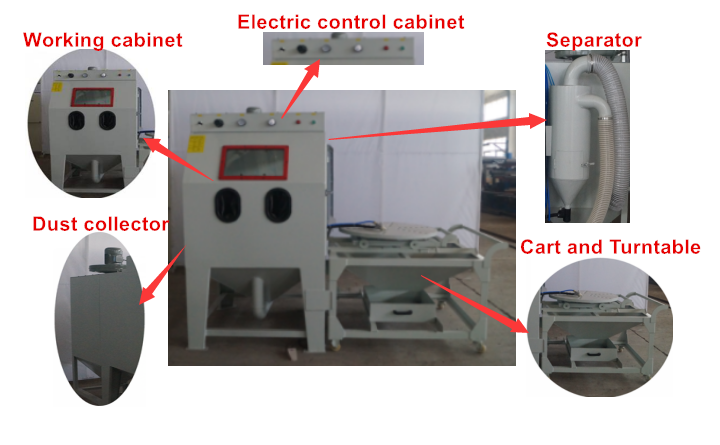

Trolley Common Sand Blast Machine, Turntable Suction Blasti Cabinet For Castings

Specifications

Working cabinet dimensions | 1000mm*1000mm*800mm |

Power Supply | 220V 50Hz |

Air pressure | 0.3-0.7Mpa(kg/cm2) |

Air consumption(Approx) | 0.8~1.2m³/min |

Quantity of process Gun | 1pc |

Load capacity | Decided by clients |

Motor for dust collector | 550W/750W AC220V 50Hz |

Machine lighting | 15W AC220V 50Hz |

Initial media charge(Approx) | 5~10Kg |

Weight of the machine(Approx) | 400Kg |

Abrasive recommended | Alumina oxide, Glass beads |

TS blast cabinets can be customized with many optional accessories like:

Boron carbide nozzles 6, 8, 10 ,12mm

Blow-off (blowing) gun

Blast gun holder

Inside rubber lining

Rubber/plastic blast gloves

Metal ring for glove attachment

Manual turntable

Feet pedal

Recommended equipment and accessories:

Abrasive media

Dust collector or recycling unit

Description:

1. This type machine is suitable for precision workpiece’s surface

treatment.

2. It can make use of fine sand materials to blast.

3. The sand materials can be recycled to use, and low sand

materials consumption, little wear-tear of nozzle, low cost.

4. Good confined, no powder dust pollution.

5. The window is large and equipped with windshield wiper, making

sure the clean visibility.

6. The simple operation, few breakdowns

7. Low noise

8. This machine is made of stainless steel, so it is durable.

9. It can add the rust inhibitor to the sand fluid, preventing iron

workpiece rusting.

Applications:

1. Pretreatment of electroplating, paint spraying, coating, etc. to

completely clean the surface and improve the adhesion and

anti-corrosion ability.

2. Cleaning the mill scale/residues/dirt of casting/pressing

/welding/heat treatment work piece, cleaning the surface of

non-metal items, cleaning the black spots on the ceramic embryo

surface, restoring paint grain pattern, etc.

3. Refurnishing sports part of car, motorcycle, electromechanical

device, etc., eliminating fatigue stress and extending working

life.

4. Removing surface marks of metal/non-metal items, dumb face and

fog treatment processing to enhance the product grade.

5. Dumb face and fog treatment of mould, text composition, mould

cleaning without damage to the mould.

6. Removing the tiny burrs of mechanical parts and injection

plastic parts.

7. Removing unqualified covering,color and printing of products.

8. Enhancing the surface hardness of metal work piece and

eliminating stress, such as processing plane vane, spring,

machining knife, weapons etc.

9. Carving patterns/words and slip resistance treatment on the

surface of metal and non-metal items, such as marble, handle

anti-skid, stamping, stele lettering, etc.

10. Sandblasting/white mark/cat’s whisker effect treatment of jeans

wear.

Competitive Advantage:

1. Dustless Sandblaster with built-in Vacuum system, No dust or

blasting abrasive flying around.

2. Abrasive can be recycled for reuse.

3. Vacuum blasting in enclosed spaces where regular blasting is not

permitted.

4. Mobile, flexible and low start-up costs.

5. Higher Efficiency, shorter clean-up time.

6. No need for special blasting rooms.

Main characteristics of the machine:

Right side door for easy loading.

Resilient-to-scratches LED lighting system for exceptional visibility

Foot pedal operated blasting

Automatic safety switch

Tool-free glass change in minutes

Actual space requirements for a complete system depends on the equipment configuration, options and requested work flow. Take care also about additional work space for the operator and for maintenance access.

Packing: