Changzhou Taisheng Machinery Equipment Co.,Ltd. |

|

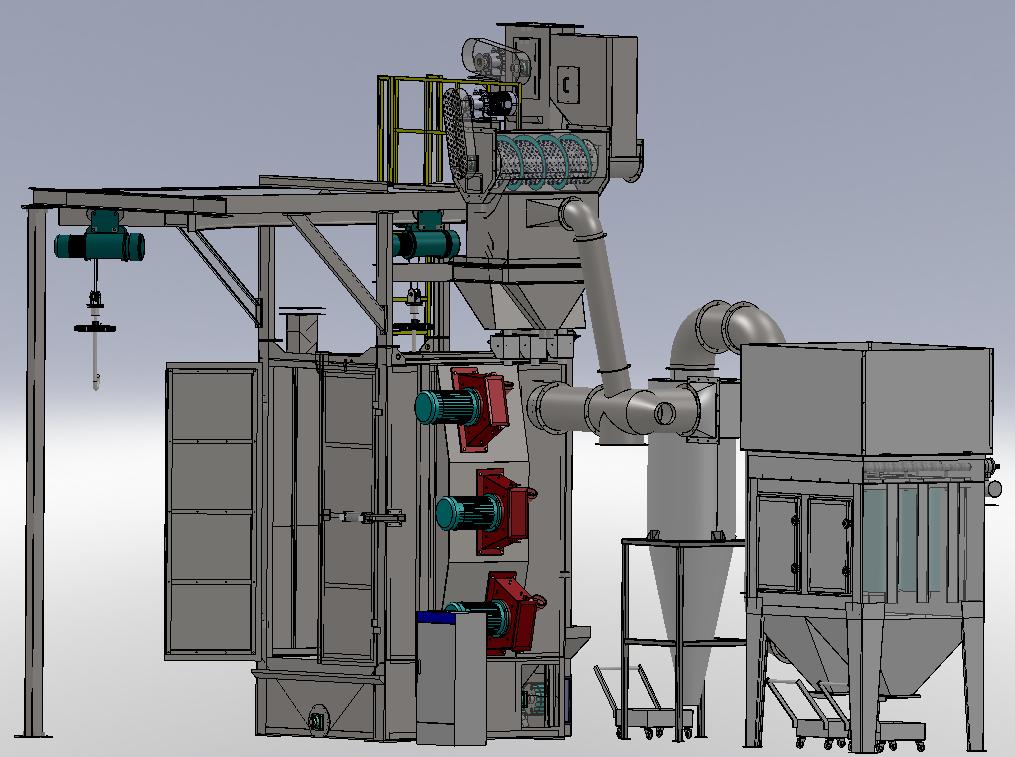

Q3710 Double Spinner Hanger Shot Blasting Machine Manual Opening Door Cleaning Forging

Quick detail

| Workpiece Description | Max part dimension | Φ1000*2000mmH |

| Max part weight | <1000kg | |

| Cleaning requirement | Meet standard of GB8923-88 A-B Sa2½, surface roughness Ra12.5 | |

| Time of cleaning one hook | Casting 8-15min; Forging 5-8min | |

| Noise Level | ≤85 dB | |

| Dust Emission | ≤80 mg/m³ | |

| Recommend Abrasive | Φ0.2~Φ1.0mm steel cut wire or steel shot | |

| Abrasive Initial Feed | 1.0-1.5T | |

| Machine Footprint | L2730mm*W5760mm* H4690mm | |

| Pit Foundation | Not required | |

| Compressed Air Consumption | <0.8m3/min | |

| Power Consumption | 32kw | |

Application possibilities

TS Spinner Hanger Machines are designed to clean a wide range of parts size and shapes. These shot blasting machines can be set up with dual swing doors, I or Y hanger and with multiple blast wheels. Parts are loaded onto a hanger and moved in, started rotating, got blasted and moved out.

Widely used in small and medium size of stainless steel parts, castings, die castings, forgings, welding structures and heat treatment parts surface cleaning and strengthening.

Advantages of using TS Spinner Hanger Machine

Machine Introduction

It is composed by shot blasting cabinet, blasting system, electrical hanger system, rotation system, abrasive recovery system, dust removal system, electrical control system and so on.

1. Blast wheel

2. Electrical Hosit

3. Hanger

4. Electrical Control Panel

5. Ladder

6. Cylone Separator

7. Dust Collector

Customer Case