Guangdong Blue Whale Ultrasonic Equipment Co;Ltd |

|

Verified Suppliers

|

|

Blue Whale Industrial Ultrasonic Cleaning Machine 61L with Two Baths Cleaning Heating Spraying

1. What is ultrasonic cleaning technology?

Ultrasonic cleaning technology is a cleaning method that utilizes high-frequency sound waves, known as ultrasonic waves, to remove contaminants from surfaces. It involves the use of specialized equipment called ultrasonic cleaners or ultrasonic cleaning machines. Here's an overview of how ultrasonic cleaning technology works:

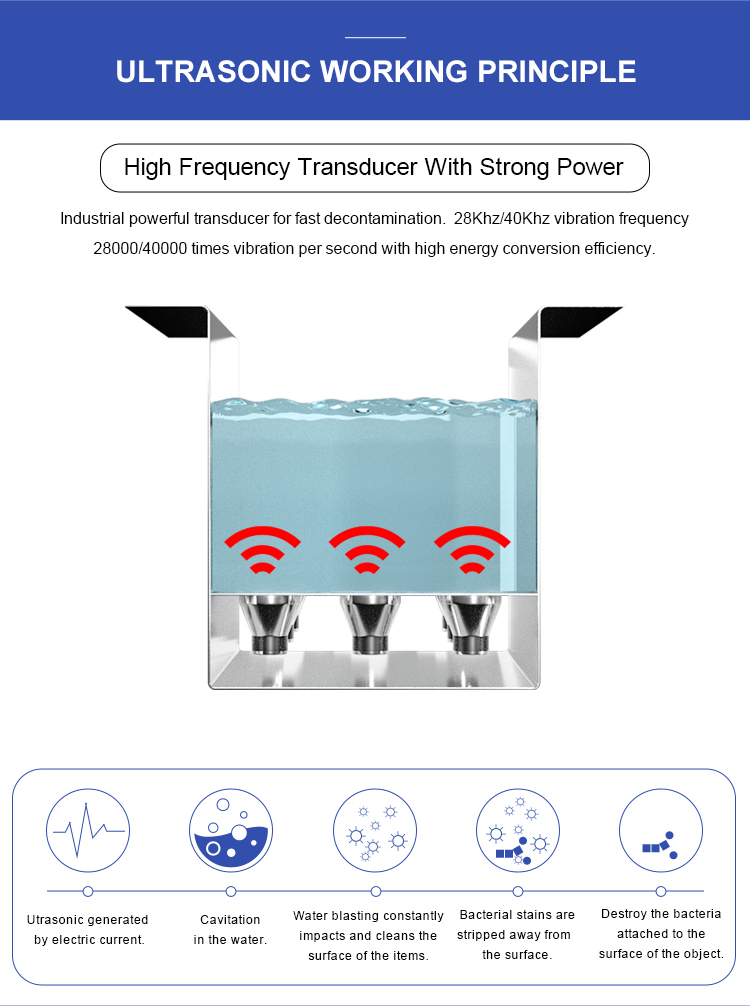

Ultrasonic Transducer: The core component of an ultrasonic cleaning machine is the ultrasonic transducer. It converts electrical energy into high-frequency mechanical vibrations. The transducer is typically made of piezoelectric materials, such as ceramics or crystals, which expand and contract rapidly when an electrical signal is applied.

Generator: The ultrasonic generator supplies the electrical energy to the transducer, producing the ultrasonic waves. The generator controls the frequency and power of the ultrasonic waves, allowing for adjustments based on the cleaning requirements.

Cleaning Tank: The ultrasonic cleaning machine consists of a tank or a chamber filled with a liquid cleaning solution. The cleaning solution can be water-based or may include specific detergents or cleaning agents, depending on the type of contaminants being removed.

Ultrasonic Waves: When the generator activates the transducer, it creates ultrasonic waves that propagate through the cleaning solution. The waves propagate as a series of compressions and rarefactions, creating alternating high-pressure and low-pressure regions in the liquid.

Cavitation Bubble Formation: In the low-pressure regions of the ultrasonic waves, small vapor-filled voids or bubbles, known as cavitation bubbles, form in the cleaning solution. These bubbles are microscopic in size and are too small to be seen with the naked eye.

Cavitation Bubble Implosion: As the ultrasonic waves continue to pass through the cleaning solution, the cavitation bubbles grow in size due to the low-pressure areas. Once they reach a certain size, they become unstable and collapse or implode when they encounter a high-pressure region of the ultrasonic waves.

Cleaning Action: The collapse or implosion of the cavitation bubbles near the surfaces being cleaned generates intense localized energy. This energy release results in the formation of microscale shockwaves, microjets, and high temperatures in the immediate vicinity of the surfaces.

Contaminant Removal: The energetic collapse of the cavitation bubbles near the surfaces creates a powerful scrubbing or agitation action. The shockwaves, microjets, and high-pressure streams of liquid dislodge and remove contaminants, such as dirt, oils, grease, scale, rust, and other residues, from the surfaces.

Thorough Cleaning: Ultrasonic cleaning is highly effective in reaching and cleaning complex geometries, blind holes, crevices, and other hard-to-reach areas. The microscopic agitation and penetration of the ultrasonic waves ensure thorough cleaning of the objects being processed.

Rinse and Dry: After the ultrasonic cleaning process, the objects are typically rinsed in clean water to remove any residual cleaning solution. They are then dried using various methods, such as air drying or using additional drying equipment.

Ultrasonic cleaning technology offers several advantages, including effective removal of contaminants, versatility for different materials and objects, and the ability to clean intricate geometries. It is widely used in various industries ranging from automotive and electronics to medical and jewelry, where precise and thorough cleaning is required.

2. Product Features:

1). Working process: the 1st tank ultrasonic cleaning with heating,

remove the rust, grease and dust from the cleaning items. The 2nd

tank high pressure spraying to provide deep cleaning service. The

alarm buzzes once complete the spraying process.

2). The inner tank material: the use of 304 stainless steel,

thickened to 2mm, manual argon welding, strong and durable;

3). Adjustable time: 1-99 minutes/hour adjustable, can be opened

often;

4). Memory function: the device has an independent memory chip, and

there is no need to reset over and over after the time is set;

5). Equipment power cord: the use of industrial thickened power

cord, safe and durable;

6). Industrial grade transducer: the use of industrial shock head,

strong force and good effect, can work 24 hours uninterrupted;

7). Generator control system: independent generator control system,

flexible control, can be set according to the user's cleaning needs

to adjust the ultrasonic power;

8). Heating automatic constant temperature system: 20-95 degrees

adjustable, equipped with stainless steel heating tube, fast

heating speed.

3. Double Tanks Industrial Ultrasonic Cleaner CHS Series:

Ultrasonic Cleaning, Heating, High Pressure Spraying

4. Can ultrasonic cleaning be used on all types of materials?

While ultrasonic cleaning is highly effective for many materials, it may not be suitable for all types of materials. The compatibility of ultrasonic cleaning with different materials depends on their specific properties and characteristics. Here are some considerations regarding the use of ultrasonic cleaning on various types of materials:

Metals: Ultrasonic cleaning is generally safe for most metals, including stainless steel, aluminum, brass, copper, and titanium. However, certain factors need to be considered, such as the material's hardness, surface finish, and susceptibility to pitting or corrosion. Soft or brittle metals, such as some precious metals or certain alloys, may require lower power or shorter cleaning durations to avoid potential damage.

Plastics: Ultrasonic cleaning can be used for many types of plastics, including acrylic, polycarbonate, ABS, and polypropylene. However, the compatibility depends on the specific plastic formulation and its ability to withstand exposure to the cleaning solution and the ultrasonic energy. Some plastics are more prone to degradation or warping and may require lower power settings or alternative cleaning methods.

Glass: Glass materials are generally well-suited for ultrasonic cleaning. However, delicate or thin glass objects, such as antique glassware or specialized optical glass, may require careful consideration of the cleaning parameters to avoid potential damage or breakage.

Ceramics: Most ceramics are compatible with ultrasonic cleaning. However, certain types of ceramics with fragile or intricate structures, such as fine china or delicate pottery, may require caution and lower power settings to prevent damage.

Rubber and Silicone: Ultrasonic cleaning can be used for rubber and silicone materials. However, it's important to consider the specific formulation and any potential sensitivity to the cleaning solution or ultrasonic energy. Some rubber or silicone materials may require testing or alternative cleaning methods to ensure compatibility.

Electronic Components: Ultrasonic cleaning is commonly used for cleaning electronic components, including PCBs, connectors, and delicate electronic parts. However, sensitive electronic components, such as microchips or certain sensors, may require lower power settings or alternative cleaning methods to prevent damage.

Delicate or Sensitive Materials: Materials such as certain gemstones, delicate jewelry, antique items, or historical artifacts may require careful consideration and testing before subjecting them to ultrasonic cleaning. It is essential to assess the material's susceptibility to ultrasonic energy, the cleaning solution, and any potential risks of damage.

It's important to note that when using ultrasonic cleaning, it's recommended to consult the manufacturer's guidelines, conduct material compatibility tests, and adjust the cleaning parameters accordingly. Every material has its unique characteristics, and understanding their limitations and sensitivities is crucial to ensure safe and effective cleaning.

5. Are there any safety precautions or considerations to keep in mind when using ultrasonic cleaning machines?

Yes, there are safety precautions and considerations to keep in mind when using ultrasonic cleaning machines. Here are some important points to consider:

Protective Gear: When operating an ultrasonic cleaning machine, it's advisable to wear appropriate personal protective equipment (PPE) such as safety goggles or glasses and gloves. This helps protect your eyes and skin from any potential splashes, aerosols, or contact with the cleaning solution.

Ventilation: Ensure that the cleaning area is well-ventilated to prevent the buildup of fumes or vapors from the cleaning solution. If necessary, use local exhaust ventilation or work in an area with adequate airflow to dissipate any potentially harmful or irritating vapors.

Cleaning Solution Safety: Take precautions when handling and using the cleaning solution. Read and follow the manufacturer's instructions and safety data sheets (SDS) for the cleaning agents or detergents being used. Some cleaning solutions may be flammable, corrosive, or have other specific handling requirements.

Electrical Safety: Ensure that the ultrasonic cleaning machine is properly grounded and connected to a suitable power source. Avoid using damaged or frayed electrical cords. Follow the manufacturer's instructions for safe installation, operation, and maintenance of the equipment.

Temperature Control: Pay attention to the temperature limits specified for the cleaning solution and the objects being cleaned. Excessive temperatures can lead to damage or deformation of certain materials. Monitor and control the temperature of the cleaning solution during the cleaning process.

Material Compatibility: Consider the compatibility of the objects being cleaned with the ultrasonic cleaning process. Some materials may be sensitive to the ultrasonic energy or the cleaning solution. Conduct material compatibility tests if necessary, especially for delicate or sensitive items.

Cleaning Time and Power: Adjust the cleaning time and power settings based on the type and condition of the objects being cleaned. Longer cleaning durations or higher power settings may not always be better and can potentially damage certain materials. Follow the manufacturer's recommendations or conduct trials to determine the optimal cleaning parameters.

Maintenance and Inspection: Regularly inspect and maintain the ultrasonic cleaning machine to ensure its safe and effective operation. Clean the tank, transducer, and other components as recommended by the manufacturer. Replace worn-out or damaged parts promptly to avoid any safety risks.

Training and Familiarity: Ensure that operators are adequately trained on the safe and proper use of the ultrasonic cleaning machine. Familiarize yourself with the user manual, safety guidelines, and any specific precautions provided by the equipment manufacturer.

By following these safety precautions and considering the specific requirements of the ultrasonic cleaning process, you can minimize risks and ensure a safe working environment when using ultrasonic cleaning machines.

6. Customer's Cleaning Feedback: