Guangdong Blue Whale Ultrasonic Equipment Co;Ltd |

|

Verified Suppliers

|

|

Blue Whale 77L Large Ultrasonic Parts Cleaner with Two Baths for Compressor Car Engine DPF Motorcycle

1. What is the advantages of the ultrasonic cleaning compared with traditional cleaning method?

Ultrasonic cleaning offers several advantages over traditional cleaning methods. Here are some key advantages:

Thorough Cleaning: Ultrasonic cleaning provides a thorough and consistent cleaning process. The microscopic bubbles created by ultrasonic waves penetrate into intricate geometries, blind holes, and hard-to-reach areas, effectively removing contaminants from all surfaces of the objects being cleaned. This level of thoroughness is challenging to achieve with traditional cleaning methods.

Non-Destructive Cleaning: Ultrasonic cleaning is a gentle process that does not cause damage to delicate or sensitive materials. Unlike aggressive scrubbing or abrasive cleaning techniques, ultrasonic cleaning relies on the power of cavitation bubbles to dislodge contaminants without causing scratches, abrasion, or surface damage.

Time and Labor Savings: Ultrasonic cleaning can significantly reduce cleaning time and labor requirements. The cleaning action is rapid and efficient, allowing for simultaneous cleaning of multiple objects. Additionally, the cleaning process is automated, requiring minimal manual intervention. This saves time and reduces labor costs compared to manual cleaning methods.

Increased Cleaning Effectiveness: Ultrasonic cleaning enhances the cleaning effectiveness by combining mechanical and chemical actions. The cavitation bubbles generated by ultrasonic waves create high-pressure streams, shockwaves, and microjets that agitate and dislodge contaminants from surfaces. The cleaning solution used in ultrasonic cleaning can be customized by adding detergents or specific cleaning agents, further improving the cleaning efficacy for different types of contaminants.

Versatility: Ultrasonic cleaning machines are versatile and can be used for cleaning a wide range of objects and materials. They are applicable to various industries, including automotive, electronics, medical, jewelry, optics, and more. The adjustable cleaning parameters, such as frequency, power, and cleaning time, allow customization for different cleaning requirements.

Environmentally Friendly: Ultrasonic cleaning is considered an environmentally friendly cleaning method. It typically uses water-based cleaning solutions, minimizing the use of harsh chemicals. Additionally, the process does not generate significant waste or pollution, making it a more sustainable option compared to some traditional cleaning methods.

Consistency and Reproducibility: Ultrasonic cleaning provides consistent and reproducible cleaning results. The controlled parameters, such as frequency, power, and cleaning time, ensure that the cleaning process is standardized and repeatable. This is particularly important in industries where consistent cleanliness levels are critical for product quality and reliability.

While traditional cleaning methods may still have their applications, ultrasonic cleaning offers distinct advantages in terms of thoroughness, precision, efficiency, and versatility. These benefits make ultrasonic cleaning a preferred choice for many industries seeking reliable and effective cleaning solutions.

2. Product Features:

1). Working process: the 1st tank ultrasonic cleaning with heating,

remove the rust, grease and dust from the cleaning items. The 2nd

tank high pressure spraying to provide deep cleaning service. The

alarm buzzes once complete the spraying process.

2). The inner tank material: the use of 304 stainless steel,

thickened to 2mm, manual argon welding, strong and durable;

3). Adjustable time: 1-99 minutes/hour adjustable, can be opened

often;

4). Memory function: the device has an independent memory chip, and

there is no need to reset over and over after the time is set;

5). Equipment power cord: the use of industrial thickened power

cord, safe and durable;

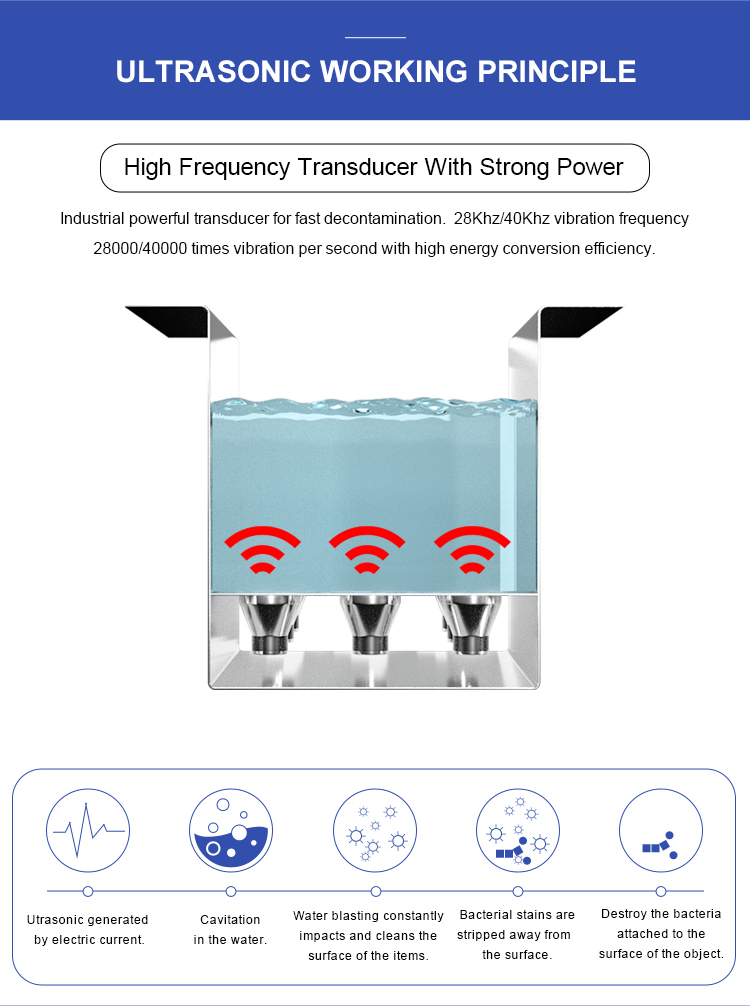

6). Industrial grade transducer: the use of industrial shock head,

strong force and good effect, can work 24 hours uninterrupted;

7). Generator control system: independent generator control system,

flexible control, can be set according to the user's cleaning needs

to adjust the ultrasonic power;

8). Heating automatic constant temperature system: 20-95 degrees

adjustable, equipped with stainless steel heating tube, fast

heating speed.

3. Double Tanks Industrial Ultrasonic Cleaner CHS Series:

Ultrasonic Cleaning, Heating, High Pressure Spraying

4. How does ultrasonic cleaning compare to other non-traditional cleaning methods?

Ultrasonic cleaning is a highly effective non-traditional cleaning method, but it's worth comparing it to other non-traditional cleaning methods to understand their differences. Here's a comparison with some commonly used non-traditional cleaning methods:

Ultrasonic Cleaning vs. High-Pressure Water Jetting:

Ultrasonic Cleaning: Ultrasonic cleaning uses cavitation bubbles

produced by ultrasonic waves to dislodge contaminants. It is

effective for intricate geometries and hard-to-reach areas. It is

gentle and non-destructive, making it suitable for delicate

materials.

High-Pressure Water Jetting: High-pressure water jetting uses a

focused stream of water at high pressure to remove contaminants. It

is effective for removing stubborn and adherent particles. It may

not be suitable for cleaning delicate or sensitive materials due to

the forceful nature of the cleaning process.

Ultrasonic Cleaning vs. Dry Ice Blasting:

Ultrasonic Cleaning: Ultrasonic cleaning uses cavitation bubbles in

a liquid cleaning solution to clean surfaces. It is effective for

removing various contaminants and is suitable for a wide range of

objects and materials.

Dry Ice Blasting: Dry ice blasting involves using compressed air to

propel dry ice pellets at high speed to clean surfaces. It is

effective for removing residues, coatings, and contaminants. Dry

ice blasting may not be suitable for sensitive materials and can

produce noise and carbon dioxide emissions.

Ultrasonic Cleaning vs. Laser Cleaning:

Ultrasonic Cleaning: Ultrasonic cleaning uses cavitation bubbles

and mechanical agitation to clean surfaces. It is effective for

removing contaminants and is widely applicable across industries.

It is gentle and does not damage most materials.

Laser Cleaning: Laser cleaning uses a focused laser beam to remove

contaminants through ablation. It is effective for precise cleaning

and can remove surface layers. Laser cleaning may not be suitable

for all materials and can generate heat and potentially cause

damage if not properly controlled.

Ultrasonic Cleaning vs. Plasma Cleaning:

Ultrasonic Cleaning: Ultrasonic cleaning relies on cavitation

bubbles to clean surfaces. It is effective for removing

contaminants and provides thorough cleaning. It is commonly used in

various industries and is gentle on materials.

Plasma Cleaning: Plasma cleaning involves using ionized gas to

remove contaminants. It is effective for surface activation,

removing organic residues, and modifying surface properties. Plasma

cleaning requires specialized equipment and may not be suitable for

all materials.

It's important to note that the choice of the cleaning method depends on the specific cleaning requirements, the nature of the contaminants, the material being cleaned, and the desired cleaning outcome. Each non-traditional cleaning method has its advantages and limitations, and the selection should be based on a careful assessment of these factors.

5. Can you explain how ultrasonic cleaning works and what makes it so effective?

Ultrasonic cleaning works based on a process called ultrasonic cavitation, which involves the generation and implosion of microscopic bubbles in a liquid cleaning solution. Here's an explanation of how ultrasonic cleaning works and what makes it effective:

Ultrasonic Wave Generation: Ultrasonic cleaning machines have a transducer that converts electrical energy into ultrasonic waves. The transducer, typically made of piezoelectric materials, vibrates rapidly when an electrical signal is applied to it, generating ultrasonic waves.

Cavitation Bubble Formation: The ultrasonic waves propagate through a liquid cleaning solution, creating alternating high-pressure and low-pressure regions. In the low-pressure regions, tiny vapor-filled voids or bubbles form in the liquid. These bubbles are known as cavitation bubbles.

Bubble Growth and Instability: As the ultrasonic waves pass through the liquid, the cavitation bubbles continue to grow due to the low-pressure areas. Once they reach a certain size, they become unstable and cannot absorb any more energy from the ultrasonic waves.

Bubble Collapse or Implosion: The unstable cavitation bubbles collapse or implode when they encounter a high-pressure region of the ultrasonic waves. This collapse is a highly energetic event and is responsible for the cleaning action.

Energy Release during Collapse: The collapse of the cavitation bubbles generates intense localized energy in the form of shockwaves, microjets, and high temperatures. This energy is released near the surfaces of the objects being cleaned.

Cleaning Action: The implosion of cavitation bubbles near the surfaces of the objects produces a powerful microscale scrubbing action. The shockwaves, microjets, and high-pressure streams of liquid generated during implosion agitate and dislodge contaminants from the surfaces.

Penetration into Complex Geometries: Ultrasonic waves can penetrate into intricate geometries, blind holes, and recessed areas of the objects being cleaned. This allows for thorough cleaning of hard-to-reach areas that are often challenging to clean using traditional methods.

Cleaning Solution and Detergents: The liquid cleaning solution used in ultrasonic cleaning machines plays a crucial role. It facilitates the cavitation process, enhances the cleaning action, and emulsifies or dissolves various contaminants such as oils, greases, dirt, and other residues.

Detergents or specialized cleaning agents may be added to the solution to improve cleaning effectiveness for specific types of contaminants.

What makes ultrasonic cleaning so effective is the combination of mechanical and chemical actions. The implosion of cavitation bubbles creates intense localized energy that can dislodge even stubborn and tightly adhered contaminants. The microscopic scrubbing action reaches all surfaces of the objects, ensuring thorough cleaning. Additionally, the penetration of ultrasonic waves into complex geometries ensures that hard-to-reach areas are effectively cleaned.

Moreover, ultrasonic cleaning is a gentle process that doesn't cause damage to most materials, making it suitable for delicate and sensitive objects. The cleaning parameters such as frequency, power, and cleaning time can be adjusted to optimize the cleaning process for different types of contaminants and materials.

Overall, the powerful and precise cleaning action, along with the versatility and adaptability of ultrasonic cleaning, contribute to its effectiveness in a wide range of cleaning applications across various industries.

6. Can you provide examples of industries that commonly use ultrasonic cleaning?

Ultrasonic cleaning is widely used across various industries due to its effectiveness in removing contaminants and providing thorough cleaning. Here are some examples of industries that commonly use ultrasonic cleaning:

Automotive Industry: Ultrasonic cleaning is used for cleaning automotive components such as fuel injectors, carburetors, intake manifolds, engine parts, brake calipers, and pistons. It helps remove carbon deposits, oil, grease, and dirt from these components.

Electronics Industry: Ultrasonic cleaning is utilized for cleaning printed circuit boards (PCBs), electronic components, connectors, and precision instruments. It helps remove flux residues, soldering residues, oils, and other contaminants from delicate electronic parts.

Medical and Dental Industry: Ultrasonic cleaning is employed for cleaning surgical instruments, including forceps, scalpels, clamps, and dental instruments such as dental drills, picks, and mirrors. It helps remove biological residues, blood, tissue, and contaminants from medical devices.

Aerospace Industry: Ultrasonic cleaning is used for cleaning aerospace components, such as turbine blades, fuel nozzles, hydraulic valves, and critical aircraft parts. It helps remove dirt, carbon deposits, lubricants, and contaminants from these components.

Jewelry Industry: Ultrasonic cleaning is applied for cleaning jewelry items like rings, necklaces, bracelets, and watches. It helps remove dirt, oils, polishing compounds, and other residues from precious metals and gemstones.

Optics Industry: Ultrasonic cleaning is utilized for cleaning precision optics, lenses, prisms, mirrors, and optical components. It helps remove fingerprints, dust, oils, and contaminants from optical surfaces.

Manufacturing and Precision Engineering: Ultrasonic cleaning is used for cleaning machined parts, molds, dies, and components before assembly or further processing. It is employed to remove cutting fluids, lubricants, and contaminants from precision-engineered parts.

Restoration and Conservation: Ultrasonic cleaning is applied for cleaning artifacts, historical objects, and museum pieces. It helps remove dirt, soot, corrosion, and contaminants from delicate and sensitive materials.

Food and Beverage Industry: Ultrasonic cleaning is utilized for cleaning equipment such as stainless steel tanks, pipes, filters, and containers in the food and beverage industry. It helps remove food residues, oils, and contaminants from processing equipment.

These are just a few examples, and ultrasonic cleaning finds applications in many other industries where thorough and precise cleaning is required. The versatility and effectiveness of ultrasonic cleaning make it a preferred choice for various cleaning applications across different sectors.

7. Customer's Cleaning Feedback: