Shanghai Genius Industrial Co., Ltd |

|

Verified Suppliers

|

|

Mig welding robot description

Robot welding is the use of mechanized programmable robots , which completely automate a welding process by both performing the weld and handling the part.

Automated and robotic MIG welding is a common process in the manufacturing industry. Robots are well suited to welding applications .They can withstand high temperatures and provide constant, consistent, high quality welds with a excellent repeatability. Plus they aren’t susceptible to health complications such as arc eye and welding burns.

Genius welding robot system introduction

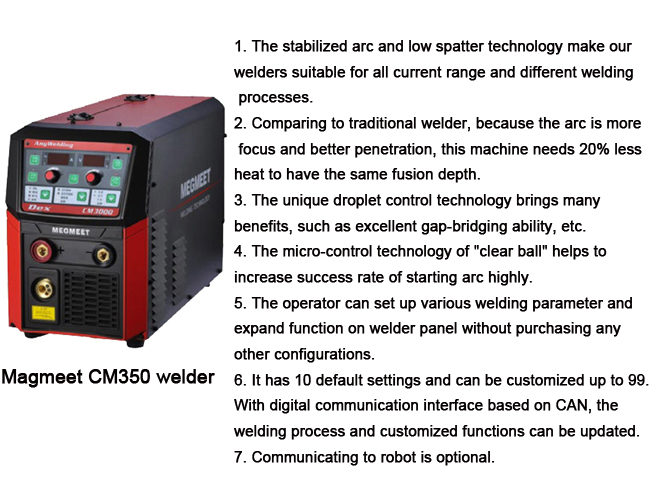

1. Welding system: Magmeet or AOTAI MIG machine, integrated automatic wire feeding system. Stable performance.

2. Automatic alarm system: if any problem on the wire feeding or

gas supply and so on, the welding robot will alarm and the welding

will stop until you clear the alarm.

3. Welding gun system: Integrated welding gun, reducing resistance

of wire through path, wire feeding smoothly.

4. Welding gun cleaning and wire cutting system: Custom made .

5. Working station positioner: It is designed with two sets of

working table. Single table could achieve 360° rotation which is

suitable for multi-angle welding. Two sets of positioner system

could achieve 180°rotation through spindle motor. It could achieve

alternative use so as to increase efficiency.

6. Work piece clamping system: the cylinders will push and clamp

the work piece. Balanced and stable clamping force.

7. Arc light baffle: cylinder pushes automatic rotation. Use for

preventing light pollution during working process.

8. Start control panel system: Touch sensing with portable

structure. Convenient for operation.

Control system functions

Integrated drive and control, open control system, comprehensive compatibility.

Robot body specification

| Robot model | ZK1400-06 | |

| Application | Arc welding | |

| Mounting | Vertical ground installation | |

| Number of axes | 6 | |

| Payload | 6kg | |

| Max working radius | 1400mm | |

| Repeated posiontioning accuracy | 0.03mm | |

| Maximum joint range | J1 | RV reducer ±160° |

| J2 | RV reducer +110°, -70° | |

| J3 | RV reducer +65°, -120° | |

| J4 | RV reducer ±150° | |

| J5 | Hollow harmonic reducer +105°, -110° | |

| J6 | Hollow harmonic reducer ±320° | |

| Maximum joint speed | J1 | RV reducer 201.9°/S |

| J2 | RV reducer 198.3°/S | |

| J3 | RV reducer 198.3°/S | |

| J4 | RV reducer 296.2°/S | |

| J5 | Hollow harmonic reducer 197.5°/S | |

| J6 | Hollow harmonic reducer 247.2°/S | |

| Allowable bending moment N.m | J4 | RV reducer 9.8N.m |

| J5 | RV reducer 9.8N.m | |

| J6 | Hollow harmonic reducer 4N.m | |

| Allowable inertia Kg.㎡ | J4 | RV reducer 0.3kg.㎡ |

| J5 | RV reducer 0.3kg.㎡ | |

| J6 | Hollow harmonic reducer 0.05kg.㎡ | |

| Body total weight | KG | 185KG |

| Operating environment | Temperature | 0℃ - 45℃ |

| Humidity | 20% - 80% | |

| Others | Keep away from corrosive gases or liquids or explosive gases, | |

| Power capacity | 6KVA (Robot) + 24KVA (Welding source) | |

Welding power source introduction

Package picture

Advantages of our company

Shanghai Genius Industrial Co.,Ltd is the overseas sales service center of Nantong Zhenkang Welding Electromechanical Company, which was established in 1993, have more than 20years of history in the welding industry.

Our company professionally manufacture wire feeder, RV gear reducer and industrial robot, which is engaging in research and development, manufacture and sell.

At present, our company occupies an area of 32,000 square meters, with a plant area of 25,000 square meters. It has 72 senior technicians, 42 technicians directly researching and developing, and total assets of 100 million CNY.

Company has advanced and sophisticated manufacturing equipments and testing instruments, CNC machine tools, machining centers, slow wire cutting machines and other equipment more than 200 units; strict quality assurance system, complete testing means; has developed into production CNC, Intelligent assembly and office automation, have realized the advanced ERP management and first - class production site of modern enterprises. The strict ISO9001 and ISO14001 system certifications provide a powerful guarantee for the company to produce high - quality wire feeders, RV reducers and industrial robots.