Anhui Oursun Resource Technology Co., Ltd. |

|

High Performance Tyre Pyrolysis Oil Distillation Plant That Turning Plastic Into Fuel

Description of waste plastic Pyrolysis Plant:

Pyrolysis plant is aimed to convert waste tires or plastics into fuel oil . In general 2.5 ton waste tyres or waste plastics can get 1 ton oil, the fuel oil through distillation can get diesel and gasoline. There is no pollution to the air, the system not only can solve solid pollution in your country but also can bring much profit to you,

Our continuous waste plastic pyrolysis plant adopts the latest pyrolysis technology, and have obtained several patents and certificates after decades of innovation and development. It has been widely recognized at home and abroad, with superior performance, competitive price, high efficiency, maintenance convenience and cost saving.

Our skilled professionals will supply customers with optimal all-in-one solutions required on civil drawings, installation & erection,supervision,

commissioning and personnel training as well as after-sale service.

Main raw material: PP, PE and PS.

Power required: around 280KWH / Ton

Daily capacity to process waste plastic: between 10 tons to 500 tons

Oil ratio: between 50% to 90% according to the different raw materials

Advantages:

Safety

Professional sealing technology for cover, oil outlet.

Zero pollution

Installation of a complete set of production process is running in the smokeless tasteless environment, protect the environment,

Warranty

2 years warranty;

Satisfied after sales service.

Technology

Can be realized under the high temperature of 350 degrees Celsius continuousfeeding and output the slag fully closed condition.

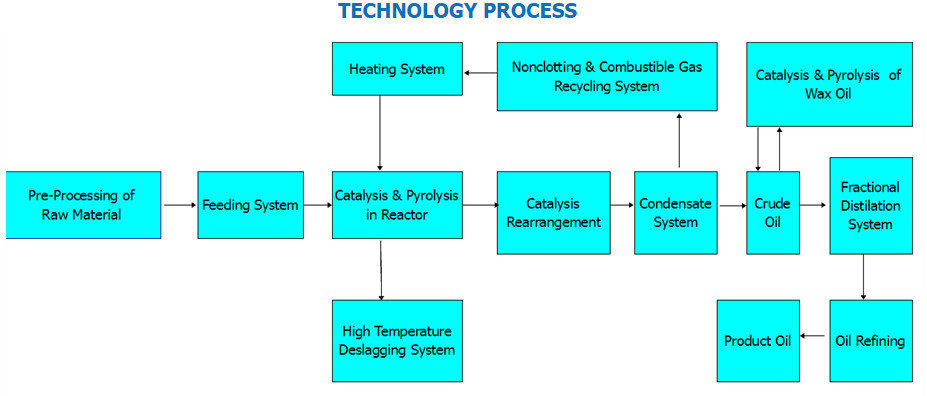

Technology and technological process

The technology and technological process of Environmental Protection and Energy Saving equipment for producing fuel from waste Plastics are developed independently by our company, which has won 4 national invention patents, 29 items of practical models. And more new technology is under researching and developing.

Environmentally friendly waste plastic pyrolysis technology has the leading level at home and abroad, especially the energy-saving technology.

The existing daily treatment of 10 tons of waste plastics and arbitrary handling capacity of the unit equipment for customers to choose.

The 4 final products we get after pyrolysis and distillation. And the usages of them is below.

1- The refining oil

(1) diesel oil (0# or 5#)

It contains 75 - 80% for all oil. And it can be used in forklift and other engineering truck, vessel, generator and etc.

(2) gasoline oil

It contains around 20% for all oil. And it can be as car oil after blending with oil of higher octain value in 1:1, or it used in gasoline generator directly.

2- Gas

It will be reused. (The combustible gas generated in processing can be recycled as fuel to heat equipment itself, which will save a lot of energy for the whole plastic pyrolysis process.)

3- Water

It will be reused as condensation water.

4- Slag

It can be made active carbon and carbon rod or combustion alongwith coal and carbon.

After sales service