Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

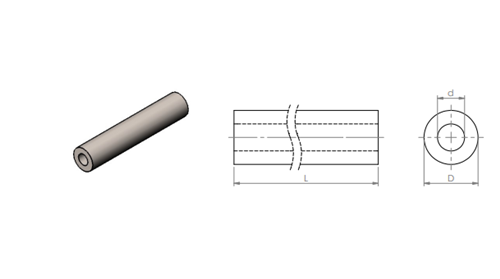

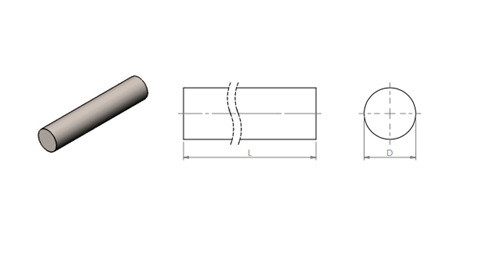

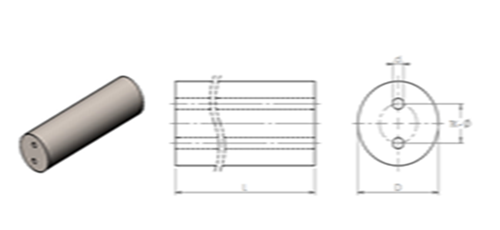

Cemented Carbide Rods K05-K40 Solid Tungsten Carbide Round Bars

Specification

Over pressure sintering tungsten carbide rod have excellent red toughness,high hardness,good wear resistance,high elastic ,high strength,good chemical stability,acid,alkali,high temperature oxidation),Low impact toughness,low

expansion coefficient,thermal conductivity,the characteristics of the conductive similar to iron and other alloy.

1. having all kind sizes for your choose,can supply less than 1000mm length.

2. Sintere by vacuum sintering furnace and HIP machine with excellent specifications without any hole.

3. Supply blank plate with tolerance(-0.15~+0.15)or (0~+0.3).

4. can grinding and polishing the diameter, making chamfer,sharper rod end.

5. process the carbide rod according your request and tolerances.

Product Application

Tungsten carbide rod is available for different grinding geometric parameters and suitable for both cutting materials and nonmetal materials, also it can be applied to conventional, carbide inserts, semi-automatic lathe, automatic lathe and planning machine to work grooves and operate cutting, etc.

As for sintered carbide bar for crusher, below are the general features for your reference. For more details of specific type, please inform us.

1. Made of first-class raw material, have more stable properties, increasing the yield of complete tools;

2. Patented design with better mechanical effect, increasing work efficiency and decreasing cost;

3. HIP sintered, have higher strength and lower breakage;

4. Special grades for different stones and rocks, maximize the performance of products.

5. Full range of types and specifications available, save your purchasing time and cost.

| Cobalt Binder Grades | ||||

| Grade | Binder(wt%) | Density(g/cm3) | Hardness(HRA) | TRS(≥N/mm2) |

| YG3 | 3 | 15.30 | 91.00 | 1180 |

| YG6 | 6 | 15.10 | 92.00 | 1420 |

| YG6X | 6 | 15.10 | 91.00 | 1600 |

| YG8 | 8 | 14.90 | 90.00 | 1600 |

| YG10 | 10 | 14.70 | 89.00 | 1900 |

| YG10X | 10 | 14.70 | 89.50 | 2200 |

| YG15 | 15 | 14.20 | 87.00 | 2100 |

| YG20 | 20 | 13.70 | 85.50 | 2500 |

| YG20C | 20 | 13.70 | 82.00 | 2200 |

| YG30 | 30 | 12.80 | 82.00 | 2750 |

Details Of Tumgsten Carbide Rod

| Outer Diameter (mm) | Inner Diameter (mm) | Length (mm) | OD Tolerance (mm) | ID Tolerance (mm) | Length Tolerance (mm) |

| φ2-7 | φ0.4-3.0 | 330 | +0.6 +0.2 | +0.0 -0.2 | +7.0 +3.0 |

| φ8-11 | φ0.4-7.0 | 330 | +7.0 +3.0 | +0.0 -0.2 | +7.0 +3.0 |

φ12-19+7.0

| φ0.4-10.0 | 330 | +0.9 +0.4 | +0.0 -0.3 | +7.0 +3.0 |

| φ20-30 | φ0.4-16.0 | 330 | +0.1 +0.5 | +0.0 -0.3 | +7.0 +3.0 |

| Specification D*L | Diameter Tolerance (mm) | Length Tolerance (mm) | Specification D*L | Diameter Tolerance (mm) | Length Tolerance (mm) |

| φ1.0-2.5*330 | +0.25 +0.15 | +7.0 +3.0 | φ15.9-19.5*330 | +0.60 -0.30 | +7.0 +3.0 |

| φ3.0-9.5-330 | -0.40 +0.20 | +7.0 +3.0 | φ20.0-29.5*330 | +7.0 +0.40 | +7.0 +3.0 |

| φ10.0-15.0*330 | +0.50 +0.30 | / | / | / | / |

| Outer Diameter (mm) | Double Inner Hole Diameter (mm) | Pitch-raw TK(mm) | Length (mm) | OD Tolerance (mm) | ID Tolerance (mm) | Pitch-raw TK(mm) | Length Tolerance (mm) |

| φ4-11 | φ0.8-1.4 | 1.72-4.85 | 330 | +0.4 +0.3 | ±0.10 | ±0.20 | +7.0 +3.0 |

| φ12-19 | φ1.75-2.0 | 5.85-8.85 | 330 | +0.7 +0.4 | ±0.15 | ±0.25 | +7.0 +3.0 |

| φ20-24 | φ2.5 | 9.80-11.75 | 330 | +0.8 +0.5 | ±0.20 | ±0.30 | +7.0 +3.0 |

| φ25-30 | φ3.0 | 11.75-13.75 | 330 | +0.9 +0.6 | ±0.25 | ±0.35 | +7.0 +3.0 |

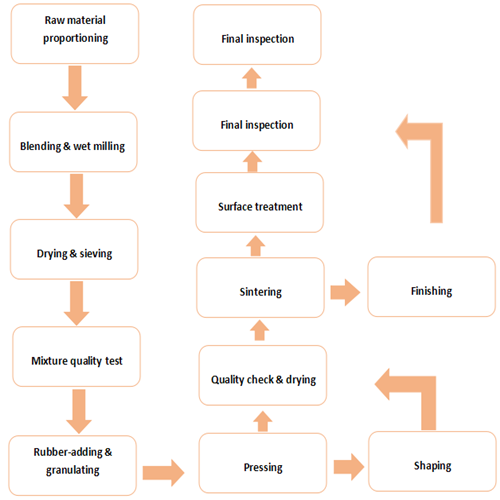

Production Process

FAQ

A1: What is your main product?

Q1: The main product include tungsten carbide bar, carbide wire drawing die, carbide drill bit button, carbide SS10 tips, carbide strip and carbide plate, anvil, carbide inserts, and any other carbide products and customized products.

A2: Do you have certification on your products?

Q2: ISO 9001:2008

A3: What is about your general delivery date?

Q3: Nomally 7-15 workdays .

A4: What is your packing?

Q4: We use standard export packing and customization is available.

A5: Can I get the samples?

Q5: Sure, contact us directly.