Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

High Performance Tungsten Carbide Rotating Bushing / Rotating Shaft

Sleeves

Features of cemented carbide bushing

1. High hard resistance

2. High corrosion resistance

3. Pressured resistance

4. Wear resistance

5. High bending strength

6. We adapt HIP sintering technology which make good quality

7. No shape change, high bending strength when temperature below 1000°C, long service life, the maximum height can reach 270mm

Application of tungsten carbide sleeve/bushing

Tungsten carbide bushing applications is widely, which is a device to protect important components. In actual working, it have a great relationship between the rule and application environment.

Valve applications as sealing parts : bushings be installed in the valve stem cap trap, in order to reduce the valve leakage, for sealing;

bearing applications as protecting parts:the use of bush to reduce wear between the bearing and the shaft seat, avoid the gap between the shaft and the hole increases and so on.

Tungsten carbide bushing production and processing of high-strength, can withstand prolonged load, with high chemical stability, alkali,alcohol,hydrocarbons, acid, oil, detergent, water (sea water), and has no smell , non-toxic, tasteless, non-rust characteristics, its widely used in petrochemical industry for Submerged Oil Pump, slurry pump, water pump, Centrifugal Pump,etc.

Grade List

| Grade |

ISO | specification | USE WAY of tungsten carbide | ||

| Density | TRS | Hardness | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG6X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

| YG6A | K10 | 14.7-15.1 | ≥1580 | ≥91.0 | |

| YG6 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

| YG8 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, nonmetal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts. |

| YS2T | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Qualified for low speed rough machining, milling titanium alloy and refractory alloy, especially for cut-off tool and silk prick. |

| YL10.2 | K30-M30 | 14.4-14.6 | ≥2100 | ≥91.5 | |

| YK25 | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Qualified for molding the drills for heavy-duty rock drill: detachable bits used for deep hole drilling, rock drill trolley etc. |

| YG11C | K40 | 14.0--14.4 | ≥2060 | ≥86.0 | |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Qualified for hard rock drilling, steel bars with high compression ratios, pipe drawing, punching tools, core cabinet of powder metallurgy automatic molders etc. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Qualified for making dies with low impact such as punching watch parts, battery shells, small screw caps etc. | |

| YG20C | 13.4-14.8 | ≥2480 | ≥82.5 | Qualified for making moulds of cold heading, cold stamping and cold pressing used for manufacturing standard parts, bearings etc. | |

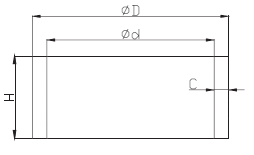

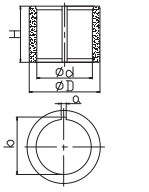

Details Carbide Bushing

| Deimensions of A Type Straight Sleeves (mm) | ||||

| Type No. | D | d | H | C |

| XA1 | 14.5-20 | 12.16 | 6.0-10.0 | 1.3 |

| XA2 | 12.5 | 3.5-7.0 | 12.7 | 4.5 |

| XA3 | 21-60 | 15-50 | 51 | 3 |

| XA4 | 75-130 | 60-115 | 55-100 | 6 |

| XA5 | 140-300 | 120-200 | 60-150 | 10 |

| Deimensions of A Type Straight Sleeves (mm) | |||

| D | d | C | H |

| 25.0-30.0 | 9.0-14.0 | 2.0-3.5 | 21.0-25.0 |

| 31.0-50.0 | 14.0-35.0 | 2.0-3.5 | 21.0-25.0 |

| 60.0-100.0 | 47.0-85.0 | 2.0-3.5 | 30.0-70.0 |

| Deimensions of A Type Straight Sleeves (mm) | |||

| D | d | H | a |

| 20.0-40.0 | 17.0-30.0 | 10.0-36.0 | 1.6 |

| 41.0-80.0 | 31.0-70.0 | 10.0-36.0 | 3.2 |

Product Application Scene

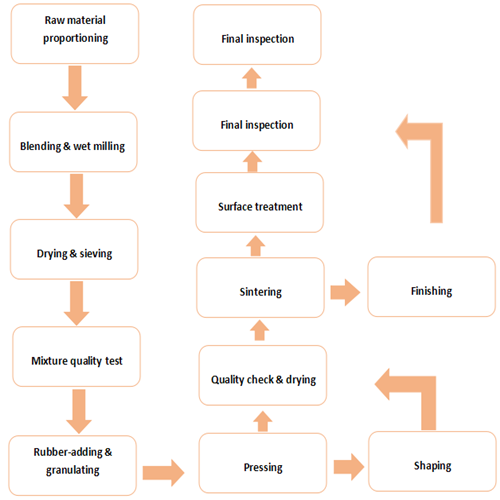

Production Process

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are factory.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is

25-35 days if the goods are not in stock, it is according to

quantity.

Q3: Do you provide samples ? is it free or extra ?

A3: Yes, we could offer the sample for free charge but do not pay

the cost of freight.

Q4: What is your terms of payment ?

A4: Payment<1000USD, 100% in advance. Payment>1000USD, 30%

T/T in advance ,balance before shipment.