Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

Solid Tungsten Carbide Wood Cutting Strip / Solid Carbide Wood Cutter Strip

Application of alloy tungsten carbide bar

carbide strip,tungsten carbide strips,tungsten carbide bar,Carbide

squre bar Carbide strip is widely used for general wood cutters /

hard wood cutters, plastic and tobacco cutting.

And it is suitable for the production of various types of motors,

electronic progressive dies punches.

Adopting HIP sintering technology and cryogenic processing technology, the inner metallographic structure of carbide strips/blanks/plates has been improved,which avoids the crack causing during the strips/blanks/plates cutting and forming process.

All of our tungsten carbide strips/blanks/plates must be strictly

inspected and only those without any harm such as pore, bubbles,

cracks etc. can be shipped out. We produce various sizes and grades

of tungsten carbide strips/blanks/plates as per client's

requirements.

Tungsten carbide strips/blanks/plates are usually used for general

wood cutters / hard wood cutters ,plastic and tobacco cutting . and

meet the ISO9001:2018 quanlity standard. We can make the

shipment in the shortest delivery time with the compeititve price

than any other factory.

We can manufacture various cemented carbide strips/blanks/plates as

per customer's requirments based on the differente markets.

Minimum grind stock: thickness: +0.2mm, width: +0.3mm, length:

+0.2mm.

Parallelism & flatness tolerances: within 0.5mm.

Quality assurance

All the produces must be inspected strictly with the ultrasonic and

only those haven't any harm such as pore can be shipped out

High density, high wear& impact resistance, which lead them a

long life time

1. Raw material purity greater than 99.95%, impurity content is

very small, the physical properties of the sheet more stable

2. Use of spray drying technology, the material in the fully sealed

conditions using high purity nitrogen protection, effectively

reducing the mixing process of oxygen preparation possibilities,

higher purity, the material is not easy to contaminate

3. Plate density uniform: 300Mpa isostatic press suppression,

effectively prevent the production defects, plate density is more

uniform

4. Board compactness is very good, strength and hardness indicators

are very good: the use of low-pressure sintering ship technology,

the plate effectively eliminate the pores, the quality is more

stable

5. Use of low-temperature treatment technology, so that the

internal micro-structure of the board can be improved, the internal

stress can be greatly eliminated, to avoid the board in the cutting

process cracks

Details of tungsten carbide plate

| Grade | YG6A | YG8 | YG15 | YG20 | YS2T | |

| ISO Code | K10 | K20 | K30-40 | K05 | K10-K20 | |

| Co | % | 6 | 8 | 15 | 20 | 15 |

| Wc | % | 94 | 92 | 85 | 80 | 85 |

| Density | G/cm3 | 14.9 | 14.7 | 14.5 | 13.5 | 14.5 |

| T.R.S | Mpa | 1850 | 2400 | 2500 | 2800 | 2350 |

| Hardness | HRA | 92 | 89.5 | 87.5 | 85.5 | 92 |

Grade List

| Grade | ISO Code | Chemical Composition(%) | Physical Mechanical Properties (≥) | Application | ||||

| WC | Co | Density g/cm3 | Hardness(HRA) | T.R.S N/mm2 | ||||

| YG3 | K01 | 97 | 3 | 14.90 | 91.00 | 1180 | Suitable for finishing of cast iron,non-ferrous metals,alloys and non-metallic materials,and semi-finishing vehicles for intermittent cutting. | |

| YG6 | K10 | 94 | 6 | 15.10 | 92.00 | 1420 | Finishing of chilled hard alloy cast iron and heat resistant alloy steel and ordinary cast iron. | |

| YG6X | K20 | 94 | 6 | 15.10 | 91.00 | 1600 | Cast iron, non-ferrous metals and alloys, non-metallic materials, medium to cutting, semi-finishing and finishing. | |

| YG8 | K20-K30 | 92 | 8 | 14.90 | 90.00 | 1600 | Suitable for casting of cast iron, non-ferrous metals and their alloys and non-metallic materials, roughing of sections and rough cutting. | |

| YG10 | K40 | 90 | 10 | 14.70 | 89.00 | 1900 | Suitable for the production of drawing dies, wear parts and stamping parts and cores for hard alloy automatic presses. | |

| YG10X | K40 | 89 | 10 | 14.70 | 89.50 | 2200 | Suitable for small diameter micro drills, end mills, rotary boring tools, etc. | |

| YG15 | K30 | 85 | 15 | 14.70 | 87.00 | 2100 | Forging, perforating and stamping tools for steel bars and steel tubes with high compression ratios and working under large stresses. | |

| YG20 | K30 | 80 | 20 | 13.70 | 85.50 | 2500 | Stamping die, stamping watch parts, musical instrument spring piece. | |

| YG20C | K40 | 80 | 20 | 13.70 | 82.00 | 2200 | punching battery case, toothpaste skin mold, small size steel ball, screw, nut stamping die, hot rolling twist drill bit plate. | |

| YG30 | G60 | 70 | 30 | 12.80 | 82.00 | 2750 | Production of standard parts, bearings, tools and other industries for cold heading, cold punching, cold pressing die. | |

| ISO Code | Grain Size (μm) | Co (mass) % | TRS (GPa) *1 | Hardness | Application | Work Material | |||||||

| HRA *2 | HV *3 | For Automatic Lathes | Cemented Carbide Plates | General Steel | Stainless Steel | Cast Iron | Non-ferrous Metal | Heat Resistant Alloy | |||||

| Cemented Carbide | K20 | <0.9 | 10 | 2.5 | 91 | 1550 | √ | √ | O | ||||

| K10 | <1.0 | 6 | 2 | 92 | 1700 | √ | √ | O | O | ||||

| M20 | <3.0 | 9 | 2 | 90.5 | 1450 | √ | √ | O | O | ||||

| Cermet | P10 | <2.0 | 18 | 2 | 91.2 | 1500 | √ | O | |||||

| P20 | <2.0 | 19 | 2 | 90.5 | 1450 | √ | O | ||||||

Detail Specification For Tungsten Carbide Strips

| Dimensions(mm) | ||||||

| L | W | R | T | |||

| 15 | ±1.0 | 3 | ±0.5 | R3 | 2~6 | ﹢0.5 |

| 15 | ±1.0 | 4 | ±0.5 | R3 | 2~6 | ﹢0.5 |

| 20 | ±1.0 | 2 | ±0.5 | R4 | 2~4 | ﹢0.5 |

| 20 | ±1.0 | 3 | ±0.5 | R3 | 2~6 | ﹢0.5 |

| 20 | ±1.0 | 4 | ±0.5 | R3 | 2~6 | ﹢0.5 |

| 20 | ±1.0 | 5 | ±0.5 | R3 | 2~6 | ﹢0.5 |

| Type Number | Dimensions(mm) | ||||||

| L | W | R | T | ||||

| 20*6*T*R3 | 20 | ±1.0 | 6 | ±0.5 | R3 | 2~6 | ﹢0.5 |

| 25*4*T*R3 | 25 | ±1.0 | 4 | ±0.5 | R3 | 2~6 | ﹢0.5 |

| 30*4*T*R3 | 30 | ±2.0 | 4 | ±0.5 | R3 | 2~6 | ﹢0.5 |

| 30*3*T*R4 | 30 | ±2.0 | 3 | ±0.5 | R4 | 2~6 | ﹢0.5 |

| 30*4*T*R3 | 30 | ±2.0 | 4 | ±0.5 | R4 | 2~6 | ﹢0.5 |

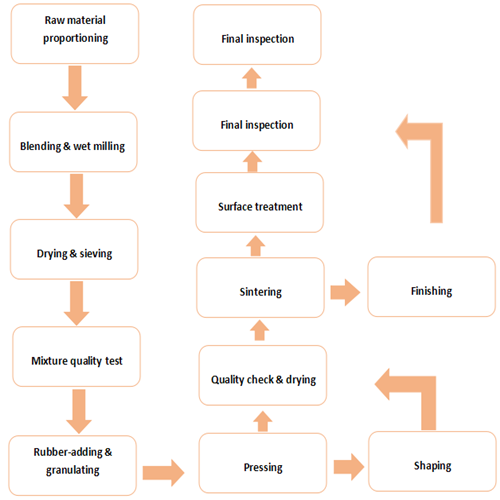

Production Process

FAQ

A1: What is your main product?

Q1: The main product include tungsten carbide bar, carbide wire drawing die, carbide drill bit button, carbide SS10 tips, carbide strip and carbide plate, anvil, carbide inserts, and any other carbide products and customized products.

A2: Do you have certification on your products?

Q2: ISO 9001:2018

A3: What is about your general delivery date?

Q3: Nomally 7-15 workdays .

A4: What is your packing?

Q4: We use standard export packing and customization is available.

A5: Can I get the samples?

Q5: Sure, contact us directly.